Table 1.

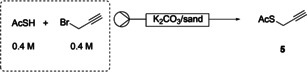

Propargylation of thioacetic acid to obtain thioester 5 in flow.[a]

|

| ||||

|---|---|---|---|---|

|

Entry |

Solvent |

Base [wt %] |

Residence t [min] |

Yield 5 [%] |

|

1 |

THF/CH2Cl2 (1:1) |

7 |

20 |

19 |

|

2 |

THF/CH2Cl2 (1:1) |

7 |

40 |

42 |

|

3 |

THF/CH2Cl2 (1:1) |

7 |

60 |

45 |

|

4 |

THF/CH2Cl2 (1:1) |

14 |

30 |

49 |

|

5 |

THF/CH2Cl2 (1:1) |

21 |

30 |

46 |

|

6 |

THF |

7 |

20 |

50 |

|

7 |

THF |

21 |

30 |

79 |

|

8 |

THF |

42 |

18 |

84 |

|

9 |

THF |

56 |

14 |

57 |

|

10 |

THF |

42[b] |

24 |

82 |

[a] Conditions: HPLC K120 Knauer Analytical pump with thioacetic acid and propargyl bromide (0.4 m) in dry solvent, column: K2CO3/sand (20 g total) in OmniSep® column (15×150 mm). [b] Column: repacked Biotage® SNAP Ultra cartridge (30 g total). The column volume and, therefore, flow rate was varied between each run due to the percentage of base.