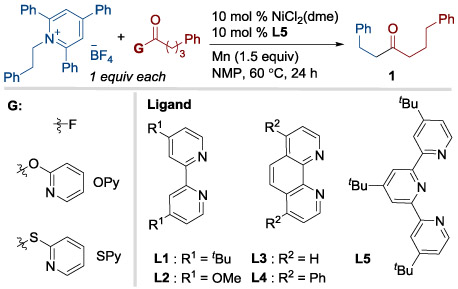

Table 1.

Optimal conditions for primary pyridinium salts.

| |||

|---|---|---|---|

| Entry[a] | Change in condition from scheme | G | 1 (%)[b] |

| 1 | None | F | 82 (79) |

| 2[c] | In situ formation of acyl fluoride | F | 75 |

| 3 | L1 instead of L5 | F | 62 |

| 4 | L2 instead of L5 | F | 65 |

| 5 | L3 instead of L5 | F | 53 |

| 6 | L4 instead of L5 | F | 41 |

| 7 | Different G | SPy | 4 |

| 8 | Different G | OPy | 11 |

| 9[e] | Zn instead of Mn | F | 5 |

| 10[d] | No nickel | F | 0 |

| 11[d] | No ligand | F | 0 |

| 12[e] | No Mn reductant | F | 0 |

Pyridinium salt (0.125 mmol, 1 equiv), acyl fluoride (0.125 mmol, 1 equiv), NiCl2(dme) (0.0125 mmol, 10 mol %), ligand (0.0125 mmol, 10 mol %), Mn (0.1875 mmol, 1.5 equiv) was stirred in NMP (0.8 mL) at 60 °C for 24 h.

GC yield vs 1,3.5-trimethoxybenzene standard. Isolated yield in parentheses.

Carboxylic acid (0.125 mmol, 1 equiv), TFFH (0.125 mmol, 1 equiv), 1,8-bis(dimethylamino)naphthylene (0.125 mmol, 1 equiv), NMP (0.8 mL).

Significant amount of acyl fluoride recovered.

Both starting materials recovered.

G = Activating Group.