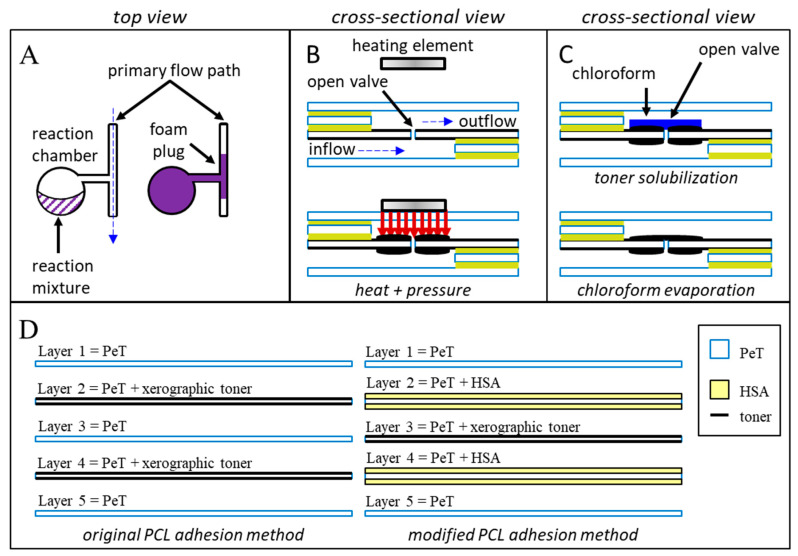

Figure 1.

Schematic diagrams of the three putative closure methods. Method (A): Foam producing reagents are manually added to upstream reagent chambers within the device. Centrifugal pumping combines and mixes the two components. Upon mixing, the rapidly expanding polyurethane foam fills and blocks the target downstream channel. Method (B): Heat and pressure are applied directly to a previously opened laser hole. Controlled compression and melting of the polymeric layers and adhesives induce intermingling and permanent bonding of the polymeric materials. Upon cooling, a permanent, channel sealing weld is formed. Method (C): Chloroform is added to a previously opened laser patch, dissolving a portion of the xerographic toner. Rapid evaporation of the chloroform redeposits the toner into a uniform layer that covers the previously ablated laser hole. (D) Microdevices featured in this manuscript consisted of five laminated PeT films that were prepared and assembled using the “print-cut-laminate” (PCL) method of fabrication.