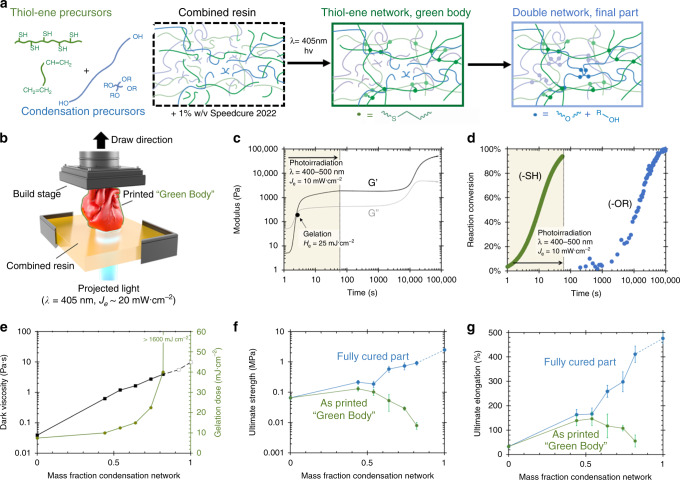

Fig. 1. 3D printing double network silicones (SilDNs).

a The precursors to a photocured thiol-ene silicone (green species) and a condensation silicone (blue species) combine to create the 3D printing resin. When exposed to light, the thiol-ene network crosslinks to form a green body that traps in the condensation components that slowly crosslink at room temperature to form the second network. These reactions are orthogonal and yield two distinct networks that occupy the same volume. b A schematic overview of the stereolithography (SLA) printing process. c, d The 82%MM10T resin’s rheological behavior (c) and the chemical conversion of crosslinkable groups (green circles denote thiol groups; blue circles denote alkoxy groups) (d) shows the independent development of the two networks during the printing process. e The dark viscosity (black line) and gelation dose (green line) of SilDN resins as a function of the relative mass fraction of the two networks. Open symbols denote compositions that are unprintable (N = 3). f, g Ultimate strength (f) and elongation (g) in the as-printed green body (green line) and final part (blue line) as a function of mass fraction of the two networks. Error bars represent the SD in measured values (N > 7).