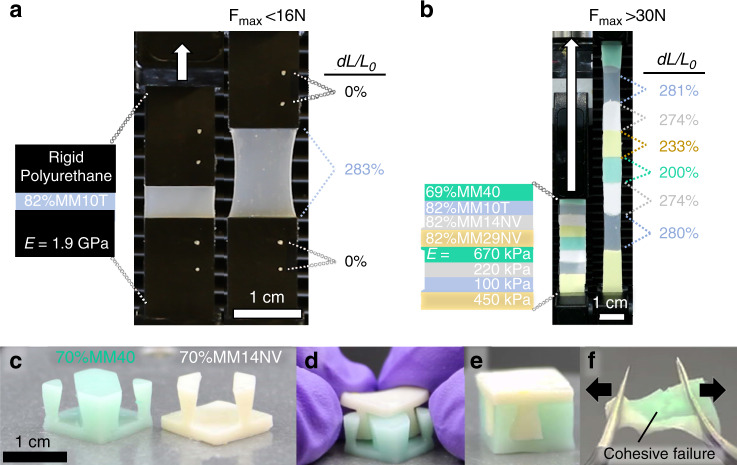

Fig. 4. Multi-material assembly of SilDNs for programmed mechanical gradients.

a A photocured 82%MM10T (E100%= 100 kPa) block is attached to rigid polyurethane segments to form a tensile coupon (3 mm thick) with a steep modulus gradient. When loaded, the strain is localized entirely to the soft SilDN section (calculated visually, white dots added for tracking). The concentration of stress at the interface causes failure prior to reaching 16 N of applied force. b SilDNs are combined post photocure to form a tensile coupon with a shallow modulus gradient. The relative strain of each segment is inversely proportional to the stiffness of the SilDN component. The smooth gradient allows this coupon to sustain a load in excess of 30 N. c A pair of objects containing complementary tapered features (dovetails) printed from different SilDN materials. d Aligning the compliant green bodies to form a mechanical interlock. e The assembly after fully curing the SilDN components shows f, cohesive failure during destructive testing.