Graphical abstract

Keywords: Fully resolved simulation, Bioaerosol, Lattice Boltzmann method, Immersed boundary method

Abstract

In recent years, manipulation of particles by inertial microfluidics has attracted significant attention. However, most studies focused on inertial focusing of particles suspended within liquid phase, in which the ratio of the density of the particle to that of the medium is O(1). The investigation on manipulation of aerosol particles in an inertial microfluidics is very limited. In this study, we numerically investigate the aerosol particle's motion in a 3D straight microchannel with rectangular cross section by fully resolved simulation of the particle–air flow. The air flow is modeled by the Navier–Stokes equations. The particle's motions, including translation and rotation, are governed, respectively, by the Newton's second law and the Euler equations without using any approximation models for the lift and drag forces. The coupled mathematical model is numerically solved by combining immersed boundary with lattice Boltzmann method (IB-LBM). We find that the Reynolds number (Re), the particle's initial position, particle's density and diameter are the influential parameters in this process. The equilibrium positions and their stabilities of aerosols are different from those suspended in liquid.

Introduction

Air pollution with suspended aerosols or airborne particulate matter (PM) has been extremely serious today, either indoor or outdoor. One of the most hazardous matter is bioaerosol, such as viruses, bacteria, pollen, fungi and enzymes, etc. Serious diseases can be caused once these airborne pathogenic microorganisms contact with human body or domestic animals, including asthma, allergies, pneumonia and infectious diseases (Douwes, Thorne, Pearce, & Heederik, 2003; Lu, He, Yu, & Hu, 2014). The epidemic Covid-19 that broke up at the end of 2019 is a rather convincing example of how fast these diseases can spread by aerosol. Therefore, rapidly and effectively detecting them is very important and crucial for disease control and human health protection (Zhang, Bi, Liu, & Qiao, 2018). To monitor these pathogenic airborne microorganisms (Hong, Kang, Lee, Kim, & Jung, 2015), the first key step is to sample bioaerosols. There are various types of bioaerosols with sizes ranging from 20 nm to 200 microns in diameter (Mazzoli & Favoni, 2012). In addition, they are suspended along with other particles, such as dusts, droplets, salts, etc. Therefore, efficient separation, collection or capture of the target bioaerosols from background environment is the foremost step prior to subsequent bioanalysis (Bian et al., 2016). Traditional methods for isolation and identification of the target aerosols, such as the semiquantitative plate sedimentation culture method (Yu, Li, Li, Tang, & He, 2017), mass spectrometry (MS) (Pietrowska et al., 2009), and loop-mediated isothermal amplification (LAMP) (Han, 2013) are time-consuming, difficult and complicated (Zhang et al., 2018).

Microfluidics, a new technique rapidly developed since 1990s, becomes another prominent method to provide direct capture and downstream airborne pathogen analysis (Metcalf, Narayan, & Dutcher, 2018; Sui & Cheng, 2014). Over the past few years, several studies have demonstrated separation of submicron aerosols and bioaerosols on microchips according to their inertial differences, size differentiation and special structure (Schaap, Chu, & Stoeber, 2012), which have shown significant advantages of being simple, rapid, portable and low-cost. For example, Chin et al. (Chin et al., 2011) used microfluidics to enable a single, easy-to-use point-of-care (POC) diagnostics and early detection of infectious diseases. Jing et al., 2013, Jing et al., 2014 successfully developed a simple microfluidic device for capture and enrichment of airborne bacteria by using an S-shaped microchannel and staggered herringbone mixer structures. Hong et al. (2015) presented a curved microchannel to separate viruses and bacteria from large particles by centrifugal force. Recently, a double-spiral sawtooth wave-shaped microchannel with herringbone structures was designed, fabricated, and tested for efficient capture of bacterial from polluted air (Bian et al., 2016). Liu et al. (2016) fabricated a first portable direct analysis system for the rapid detection of airborne pathogen using a microfluidic chip which has both enrichment and identification functions. Yin, Wan, and Mason (2017) demonstrated an I-shape pillar-based deterministic lateral displacement (DLD) microfluidic device for portable and real-time monitoring of PM2.5.

However, the aforementioned designs mainly depend on experience. The particle's detailed motion in microchannels remains unclear, though a large body of research has been devoted to particles’ motions suspended in liquid (Lu, Liu, Hu, & Xuan, 2017; Su, Chen, & Hu, 2018; Zhang et al., 2016) instead of air. In a straight liquid microchannel, initial randomly distributed neutrally buoyant particles will finally migrate to several symmetric equilibrium positions due to the inertial effect (Liu, Hu, Jiang, & Sun, 2015; Martel & Toner, 2014; Zhang et al., 2016). The viscoelasticity of fluid (Xiang, Dai, & Ni, 2016; Yuan et al., 2018) and complex channel (Jiang, Huang, Zhao, Tang, & Xiang, 2018; Kim et al., 2016) also significantly affect the particle migration dynamics. However, the aerosol particles are no longer neutrally buoyant in air since the properties of air medium are significantly different from those of liquid medium, especially density and viscosity. The dynamics and transport process of aerosol particles are expected to be different from those of particles immersed in liquid medium. Motivated by this and the spread of Covid-19 virus in aerosol particles, we investigate the detailed dynamics of aerosol particles in microfluidic channels by fully resolved simulation based on immersed boundary-lattice Boltzmann method (IB-LBM) without using any empirical formula for forces acting on the particle.

Theoretical analysis

The air flow in a microchannel can be described by the Knudsen number, Kn = λ/L, which is the ratio of the mean free path of air, λ, to the representative geometry length scale, L. Here, L is the hydraulic diameter of the straight, 3D microchannel with a rectangular cross-section, D h = 2HW/(H + W), with H and W being height and width of the microchannel, respectively. The calculated Kn << 1.0 according to the physical conditions in this study, suggesting that the flow is continuum in the current study and the geometry boundary is no-slip. On the other hand, the aerosol particles simulated in this work are finite size with diameters ranging from 2.5 μm to 10 μm and the corresponding Peclet number is significantly larger than 1. Therefore, the Brownian motion is minor and can be ignored. In addition, the particles are assumed to be rigid, spherical and inertia, and the research focuses on their inertial migration behaviors in a straight, 3D microfluidic channel.

Subsequently, the differences between the air–particle system and the conventional liquid–particle system are discussed. As shown in Table 1 , the physical parameters of the two systems, such as particle density ρ p, particle diameter D p, channel height H, and inlet fluid average velocity U f, are set to be the same. The air density ρ f is 1.205 kg/m3, which is much lower than that of liquid with 1000 kg/m3. This yields that the fluid kinematic viscosity in the air–particle system is larger than that in the liquid–particle system, while the fluid dynamic viscosity in the former is much lower than that in the latter system. For example, the dynamic viscosity μ f and kinematic viscosity ν f of air are approximately 1.79 × 10−5 Pa s and 1.48 × 10−5 m2/s, respectively. Those of liquid (i.e., water), however, are approximately 1.01 × 10−3 Pa s and 1.01 × 10−6 m2/s, respectively. As a result, the fluid's inertial, i.e., channel Reynolds number, is considerably smaller in the air–particle system than that in the liquid–particle system. In contrast, the particle's inertial, i.e., Stokes number (Brennen, 2005), is far greater in the air–particle system than that in the liquid–particle system. Here, the channel Reynolds number Re c and particle Stokes number St p are defined as follows (Akhatov, Hoey, Swenson, & Schulz, 2008b; Hoey, Lutfurakhmanov, Schulz, & Akhatov, 2012):

| (1) |

| (2) |

where τ p and τ f are, respectively, the relaxation times of the particle motion and fluid flow. Particles with small Stokes number can easily follow the fluid flow, while particles with large Stokes number can detach from fluid flow when the fluid flow changes magnitude or direction. Large Stokes number will also induce particles to lag behind the fluid in fluid-driven particle motion, and produces a larger slip-shear velocity between particle and fluid (Akhatov, Hoey, Swenson, & Schulz, 2008a; Deng et al., 2008; Jebakumar, Premnath, & Abraham, 2016). As shown in Table 1, particle Stokes number is merely 0.22 at moderate Reynolds number (Re c = 100) in a liquid–particle system, while it becomes 12.54 at low Reynolds number (Re c = 6.8) in an air–particle system. Therefore, the ratio of the particle Stokes number to fluid Reynolds number in an air–particle system is 1.84, which is nearly 103 times of that in a liquid–particle system (i.e., 2.2 × 10−3). This result suggests that the particle's inertia is relatively more significant in the air–particle system.

Table 1.

Comparison of parameters in a liquid (water)–particle system and an air–particle system in a square microfluidic channel.

| Parameters | Liquid–particle system | Air–particle system | ||

|---|---|---|---|---|

| Same | Particle density, ρp | 1000 kg/m3 | = | 1000 kg/m3 |

| Particle diameter, Dp | 5 μm | = | 5 μm | |

| Channel height, H | 25 μm | = | 25 μm | |

| Inlet fluid average velocity, Uf | 4.04 m/s | = | 4.04 m/s | |

| Difference | Fluid density, ρf | 1000 kg/m3 | >> | 1.205 kg/m3 |

| Fluid dynamic viscosity, μf | 1.01 × 10−3 Pa s | >> | 1.79 × 10−5 Pa s | |

| Fluid kinematic viscosity, νf | 1.01 × 10−6 m2/s | < | 1.48 × 10−5 m2/s | |

| Channel Reynolds number, Rec | 100 | >> | 6.8 | |

| Particle Stokes number, Stp | 0.22 | << | 12.54 |

In order to explain particle's motion and behavior, we further analyze forces acting on particles. In the liquid–particle system, there are two dominant forces: shear gradient lift force induced by the parabolic velocity profile and the wall induced lift force caused by the hydrodynamic repulsive effect between particle's surface and channel wall (Amini, Lee, & Di Carlo, 2014; Martel & Toner, 2014; Zhang et al., 2016). The former force directs towards the wall and the latter towards the channel centerline, as schematically shown in Fig. 1a. The balance of these two forces eventually focused the particle to an equilibrium position in the crossflow direction. However, in an air–particle system, there are at least two additional forces, as shown in Fig. 1b. One is the Saffman lift force (Akhatov et al., 2008a, Saffman, 1965) induced by the large slip-shear velocity between fluid and particle. This force directs towards the channel centerline when the particle lags behind the fluid, while towards the wall when it leads the fluid. The other is the buoyant force as a result of the large density ratio of the heavy particle to the air fluid, which approximates O(103). Its direction remains towards downward because the gravity always directs towards downward. In fact, because the particle has a finite size, the slip-shear velocities between its two ends, one of which is close to the channel center with a high air velocity and the other is close to the channel wall with a low air velocity, are unequal. This may cause the particle to rotate and generates another lateral force on the particle, called Magnus force (Barkla & Auchterlonie, 1971). Its direction changes depending on the rotation direction of the particle and its magnitude depends on the relative angular rate (Hoey et al., 2012). Therefore, there are at least four or more forces governing the particle motion in an air–particle system. In addition, the smaller dynamic viscosity in the air–particle system can cause the velocity profile to be steeper with much larger shear rate (Bruus, 2008), as shown in the left part of Fig. 1b. This will increase the shear gradient lift force. As a result, the force acting on a particle in an air–particle system is much more complicated and significantly distinct from that in the liquid–particle system. Note that Akhatov's group (Akhatov et al., 2008a, Akhatov et al., 2008b, Hoey et al., 2012) have extensively explored the force model of particle motion for the 3D direct-write technologies based on aerosol jet system. However, their model is not applicable for the conditions in this study. One reason is that the fluid velocity is very high (50–200 m/s) in the aerosol direct-write system with a certain compressible effect, while it is low (less than 10 m/s) in the aerosol sampling system with incompressible effect. Another reason is that the finite size of the particle in the former system is neglected, which should be considered in microfluidics as indicated by many previous literatures (Amini et al., 2014; Amini, Sollier, Weaver, & Carlo, 2012; Di Carlo, Edd, Humphry, Stone, & Toner, 2009) and the simulation results depicted in Section “Results and discussions”.

Fig. 1.

Forces acting on a particle in (a) a liquid–particle system and (b) an air–particle system.

In this work, we implemented the fully resolved direct numerical simulation (FR-DNS) (Maxey, 2017) based on immersed boundary-lattice Boltzmann method (IB-LBM) to consider all the forces and the finite-size effect. By doing this, the construction of the complicated force model acting on a particle is avoided, while it is the key in the conventional Euler-Lagrangian method based on a point particle model (Akhatov et al., 2008b; Lee, Hwang, Kim, Kim, & Lee, 2013; Tavakoli, Mitra, & Olfert, 2011). The current study aims to present a detailed and consolidated comparison between single particle focusing behavior in the air–particle system and the conventional liquid–particle system. The effects of channel Reynolds number, particle's initial position, particle's diameter, and particle's density are considered.

Numerical methods

The numerical simulations were carried out by an in-house CFD code, PFlows, based on the immersed boundary coupling with lattice Boltzmann method (IB-LBM) (Jiang, Li, & Liu, 2020a, 2020b; Jiang & Liu, 2019; Jiang, Zhang, & Liu, 2018). The lattice Boltzmann method (Aidun and Clausen, 2009, Chen and Doolen, 1998) has been a popular CFD numerical tool due to its advantages in simplicity, meshless, efficiency, and parallel scalability. Ladd (Chun and Ladd, 2006, Ladd, 1994a, Ladd, 1994b) employed the LBM for the simulation of particle migration behaviors in straight channels and calculated the interaction forces. It has been used by several groups in the research of liquid–particle system in microfluidics (Asmolov, Dubov, Nizkaya, Harting, & Vinogradova, 2018; Haddadi & Di Carlo, 2017; Wu, Chen, Wang, & Chung, 2016) and gas–particle system (Lu, Liu, Li, et al., 2017; Xiong et al., 2012). Recently, immersed boundary method (IBM) (Mittal & Iaccarino, 2005) was further coupled with the LBM to overcome certain shortcomings, such as calculation complexity of distinguishing interface between particle boundary and fluid, particle boundary unsmooth and pseudo oscillation of hydrodynamic force. Sun et al. (Jiang, Tang, Xiang, & Ni, 2016; Sun & Bo, 2015; Sun, Jiang, Xiang, Chen, & Ni, 2013; Sun, Wang, Dong, & Sun, 2016) have successfully applied this method to the particle–fluid interaction and complex particle dynamics in fluid–particle systems, including the moving, rotation, migration and focusing of a single particle or particle group in straight and non-straight microchannels.

In the IB-LBM coupled method, the fluid flow is solved by LBM based on fixed Cartesian orthogonal lattices and the particle is represented by a large number of moving Lagrangian points uniformly distributed at its surface. The particle–fluid hydrodynamic interaction is solved by the communication between the fixed fluid lattices and the moving surface points at the local region near the immersed particle surface (boundary). The details and validations of the numerical method can be referred to Jiang and Liu (2019), Jiang, Qian, and Liu (2018), which is briefly described below.

Immersed boundary-lattice Boltzmann method

For incompressible viscous flows laden with particles in this case, we adopt the single-relaxation time (SRT) LBGK model with the external force term (Guo, Zheng, & Shi, 2002a; Qian, D’Humières, & Lallemand, 1992) as

| (3) |

where f α is the velocity distribution function of a fluid particle moving in the αth direction. In this study, 19 discrete directions of the D3Q19 model for 3D flows are adopted. e α is the discrete velocity. The discrete velocity vectors e α are given by

| (4) |

where the lattice speed , and are respectively the lattice spacing step and time step. is the equilibrium distribution function with a form of

| (5) |

with u being the fluid velocity. w α is the corresponding weighting coefficients, as w 0 = 1/3, w 1–6 = 1/18, and w 7–18 = 1/36. The last term F α(x,t) at the right-hand side of equation (3) is the external force term, defined as

| (6) |

where f(x,t) is the local force term acting on the fluid calculated by immersed boundary method. τ is the dimensionless relaxation time, determined by . The fluid density ρ f and velocity u corrected by the contribution from the immersed boundary force density f(x,t) are as follows:

| (7) |

| (8) |

The immersed boundary method is usually implemented in three main steps:

Velocity Interpolation: the first step is to solve the intermediate fluid velocity u bn at the particle surface by interpolating the fluid velocity u f from the nearby Eulerian lattices (x f, y f, z f) to the Lagrangian points (X n, Y n, Z n), as

| (9) |

Boundary force calculation: the second step is calculating the IB-related force density at the Lagrangian points according to the no-slip boundary condition

| (10) |

Boundary force spreading: the third step is spreading the obtained force density F bn from the Lagrangian points to the neighboring Eulerian lattices

| (11) |

where drs n and dA n are respectively the boundary thickness and the surface area of the surface point n. The obtained boundary force density f f can be substituted to the right-hand side of the Eqs. (6) and (8) to correct the fluid flow. In the interpolation and spreading steps according to Eqs. (9) and (11), the regularized Dirac delta function δ ij (·) is used, due to its smooth, compact support and calculation efficiency. Here we use the 4-points functions (Peskin, 2002) corresponding to the maximum scope of influence being 4 lattices for each boundary Lagrangian point as:

| (12) |

Based on this, the hydrodynamic force F h and moment T h acting on the particle can be directly calculated by integrating the surface forces and moments as:

| (13) |

| (14) |

with r n being the arm of the force.

Governing equations for particle motion

The governing equations for the translational and rotational motions of particles using the Newton's second law are as follows:

| (15) |

| (16) |

| (17) |

| (18) |

| (19) |

| (20) |

where m p and I p are the mass and moment inertia of the pth particle, respectively. a p, u p, α p, w p, and θ p are the translation acceleration and velocity, rotational acceleration, rotational velocity and angular of the pth particle, respectively. The second term of the right-hand side of Eq. (15) represents the buoyant force as F b = (ρ f/ρ p − 1.0)·m p g, which is constant due to the constant densities of fluid and particle. The term F p-p/w is the short range interaction force between particle and particle/wall, which can be calculated by lubrication model when the net distance between the particle surface and the channel wall is less than a lattice (Nguyen & Ladd, 2002).

Code validation

To validate the accuracy of our in-house code based on the IB-LBM, two benchmark cases were implemented. The first one is the lateral migration of a freely moving and neutrally buoyant particle in a 3D square microchannel filled with liquid at Re c = 100, referred to the previous literature (Lashgari, Ardekani, Banerjee, Russom, & Brandt, 2017). The geometry and the particle migration trajectories in the channel cross-section are shown in Fig. 2a and b. Two obvious migration steps were observed: the first fast migration from the initial position to the equilibrium plane parallel to the wall and the second slow migration to the final equilibrium position along the isoplane of the streamwise velocity. In addition, the particles from different initial positions except the symmetric planes migrated to the same equilibrium position (approximately 0.2H away from the channel wall). The qualitative migration processes and quantitative equilibrium position both agree well with the literature (Lashgari et al., 2017). In the second case, we calculated the lateral lift force coefficient f L = F z/(ρ f U3 f/H) for further quantitative comparison, which has been obtained by Di Carlo et al. (2009) and Nakagawa et al. (2015) with finite element method and immersed boundary method, respectively. F z is the lateral lift force on the particle and can be solved by Eq. (13). In this case, the particle is fixed in the y and z directions while freely moving in the streamwise x direction and freely rotating in any direction. The results are shown in Fig. 2c, which shows that our results also agree well with the corresponding results from the literature (Di Carlo et al., 2009, Nakagawa et al., 2015).

Fig. 2.

(a) Flow visualization of the motion of a single particle in a square duct. (b) Lateral trajectories of individual particles projected onto the streamwise velocity gradient plane in one-eighth of a square duct at Rech = 100. The ratio between particle diameter and duct height is dp/Hch = 0.2. (c) Non-dimensional lateral forces, fL, on a particle when the particle is placed on the x–y middle plane for dp/Hch = 0.22 and Rech = 40. The corresponding results for fL obtained by Di Carlo et al. (2009) and Nakagawa et al. (2015) are shown by hollow red squares and blue hollow circles, respectively.

Simulation setup

In this work, a straight microchannel with constant square cross-section was used and scaled as L × H × H = 90 × 20 × 20 μm, as shown in Fig. 3a. The Poiseuille flow in this microchannel is driven by the pressure difference ΔP applied between inlet and outlet. The hollow arrowhead depicts the flow direction. The fluid flow are characterized by an approximate theoretical average bulk velocity U f and the corresponding channel Reynolds number defined as U f = ΔPH 2 /32μ f L and Re c = ρ f U f H/μ f (Sun et al., 2016), respectively. The inlet and outlet boundary conditions are set to be periodical. The velocity and pressure boundary conditions at the wall, inlet and outlet are implemented by non-equilibrium extrapolation method with second order accuracy (Guo, Zheng, & Shi, 2002b). The lattice grid step is set as Δx = 0.3125 μm after grid independence test for the uniform and orthogonal lattices, as shown in Fig. 3b. The number of the lattices is 289 × 65 × 65 = 1.22 million. The resolution of particle diameter is d p/Δx = 16 for the PM5.0 particle and 790 Lagrangian points are uniformly distributed at its surface to represent the particle. The time step is set as Δt = 2.5 × 10−9 s to ensure that the relaxation time τ and Mach number Ma can satisfy 0.5 < τ < 1.0 and Ma << 1 for accuracy and stability requirements. Initially, the fluid flow is fully developed and the particle is static (i.e., the initial velocity of the particle is zero). In addition, all the calculations are speedup by MPI parallel strategy on 12 computational cores.

Fig. 3.

Computational setup: (a) the streamwise velocity at different cross section of the microchannel when the PM5.0 particle reaches its equilibrium position at Rec = 2.0. (b) The computational fluid lattice used in the numerical simulation. (c) The Lagrangian points distributed on the particle surface.

Results and discussions

Interactions between fluid and particle

In the present work, the simulation is firstly carried out for PM5.0 particle at Re c = 2. Fig. 4 shows the air streamwise velocity, shear rate and shear rate gradient at the cross section of the straight microchannel. The air velocity, shear rate and the shear rate gradient are all significantly disturbed due to the presence of a finite-size PM5.0 particle. When particle is absent, they are symmetrical based on the horizontal midline, vertical midline and diagonal lines, as shown in Fig. 4a–c. The maximum value of the velocity and the minimum value of the shear rate are at the center of the channel, while the minimum values of the shear rate gradient are positioned at the four diagonal lines. However, when a particle is present, it occupies a certain volume and hence changes the distribution of flow field around the particle to be asymmetrical, as shown in Fig. 4d–f. In addition, the shear rate and shear rate gradient are bigger in the vicinity of the particle. These phenomena are the results of the relative slip motion between particle and fluid caused by the large value of particle's Stokes number, and will have significant influence on the particle's motion. For example in Fig. 4e, the shear rate at the bottom zone below the particle is much larger than that at the overhead zone above the particle. This will cause particle to rotate from up to bottom, with the direction depicted by the red dashed arrow. Rotation will generate the Magus force (Barkla & Auchterlonie, 1971) to push the particle moving towards the channel center. However, it should be pointed out that this effect cannot be obtained by the traditional Eulerian-Lagrangian method, in which the particle is only treated as a Lagrangian point.

Fig. 4.

Fluid streamwise velocity, shear rate and shear rate gradient with and without a particle in the straight microchannel at Rec = 2. (a)–(c) Pure fluid without particle; (d)–(f) Fluid with a single PM5.0 particle. (a) and (d) Streamwise velocity; (b) and (e) Shear rate calculated based on the streamwise velocity; (c) and (f) Shear rate gradient calculated based on the streamwise velocity. The locally disturbed zones affected by the particle are approximately depicted by the enclosed dashed black curves. The dashed red curve line in (e) represents the particle rotational direction as from paper to outside and then downside.

Fig. 5 shows the middle x-z plane view of the fluid pressure P*, streamwise velocity U and vertical velocity W in the presence of a single particle located at non-symmetrical position Z* = 0.85 (Fig. 5a–c) and symmetrical position Z* = 0.5 (Fig. 5d–f). The pressure P* has been nondimensionalized based on P 0 as P* = P/P 0. The particle's coordinates have been nondimensionalized based on the channel height as X* = x p/H, Y* = y p/H and Z* = z p/H. The pressure strip from left to right can be obviously observed in Fig. 5a and d because the fluid is driven by the pressure difference ΔP between left inlet with P in = P 0 + 0.5ΔP and the right outlet with P out = P 0–0.5ΔP. The flow field is significantly disturbed by the particle only at the local positions closed to the particle. Due to the interaction between particle and channel wall, fluid pressure is low at left and high at right over the particle, while high at left and low at right below the particle, as shown in Fig. 5a. This will promote on the particle's surface from left to right at the lower part of the particle and from right to left at the upper part of the particle, and hence generates a particle rotation with a counter-clockwise direction as depicted by the black curved arrow in Fig. 5a. Conversely, the particle counter-clockwise rotation will induce fluid flowing upward at right and downward at left in Fig. 5c because the non-slip boundary condition should be satisfied. However, when the particle is located at the central plane between the top and bottom walls, both the fluid pressure and velocity are symmetric about the particle's horizontal axis, as shown in Fig. 5d–f. The symmetrical distribution of pressure cannot induce particle rotation.

Fig. 5.

Middle x–z plane view of the contour plot of the fluid dimensionless pressure P* (P* = P/P0), streamwise x-velocity U and vertical z-velocity W in the microchannel for particle's location at Z* = 0.85: (a)–(c) and Z* = 0.5: (d)–(f) at Y* = 0.5 and Rec = 2.

Furthermore, the pressure distribution at the particle's surface is obtained by interpolation calculation as shown in Fig. 6 . The dimensionless pressure coefficient is defined as C p = (P – P 0)/(0.5ρ f U 2). The pressure coefficient at the position closing to the wall is relatively larger than that located at the channel center. It is symmetrical about the horizontal axis, large at the upstream surface and small at the downstream surface, as shown in Fig. 6b and d. Therefore, the particle can be pushed by the pressure difference at its surface and translate horizontally with no rotation. However, the distribution of the pressure coefficient is non-uniform when the particle is near the channel wall. As can be seen in Fig. 6a and c, the pressure difference between upstream surface and downstream surface is negative on the upper part while positive on the lower part. Hence, the generated pressure forces F 1 and F 2 produce moment about the particle's center with arm L 1 and L 2, ultimately yielding particle rotation in the counter-clockwise direction.

Fig. 6.

The contour plot of the dimensionless pressure coefficient at the particle surface with its center located at Z* = 0.85 (a, c) and Z* = 0.50 (b, d) at Rec = 2.0 and = 830. Red curved arrows depict the rotational direction of the particle.

Particle's motion and focusing

We fix the particle at y and z coordinates and it translates in x direction with free rotation. Fig. 7a and b shows the streamwise velocity u p and dimensionless angular velocity ( = 0.5d p ω p/U f) of the PM5.0 particle for different particle density ratios, ( = ρ p/ρ f). The particle's velocities are lower than the fluid velocities at the same positions, as shown in Fig. 7a. Particles with high density ratio, i.e., heavier particles, have lower velocities. It suggests that these aerosol particles lag behind fluid, and heavier particles lag behind even more, which are the source of the Saffman force as described in Section “Theoretical analysis”. Interestingly, we find that the dimensionless angular velocity varies linearly with the particle position Z*, and is not affected by the particle density (Fig. 7b). The value of the dimensionless angular velocity is positive when the particle is at the lower part (Z* < 0.5), and becomes negative when the particle is at the upper part (Z* > 0.5). This suggests that the passive particle driven by the Poseuille flow always rotates in a direction from channel center forward to channel wall and experiences Magnus force towards channel center, as shown in Fig. 7(c). When it travels through channel center from upward to downward the direction of the rotation and corresponding Magnus force will reverse.

Fig. 7.

Dimensionless streamwise velocity, angular velocity and lateral lift force coefficient of a single particle with different densities located at different Z* positions and at Rec = 2.

The lateral lift force coefficient f L is also obtained as shown in Fig. 7d. The lift force coefficient of the aerosol particle has the same trend as that of the neutrally buoyant particle in the liquid–particle system (in Fig. 2c). The points A and B corresponding to zero value of f L are the lower and upper equilibrium positions. And the heavier particle prefers an equilibrium position slightly closer to the channel center. Point C may be also an equilibrium position, which is higher than the channel center due to the balance of the lift force to the negative gravity. However, we consider that it is an unstable equilibrium position like that in the liquid–particle system (Abbas, Magaud, Gao, & Geoffroy, 2014; Nakagawa et al., 2015).

Next, the particle is placed at different initial positions Z* at the fixed symmetric and vertical midline Y* = 0.5 to freely move after the fluid flow is calculated to be stable. Fig. 8 shows the trajectories of a single particle. Particles eventually reach two stable equilibrium positions (upper Z* 1 = 0.756 and lower Z* 2 = 0.241) after experiencing an overshoot. This overshoot is due to the large relative velocity difference between fluid and particle at the beginning, which generates large Saffman force (Fan, McFarland, & Anand, 1992) driving particles moving towards the channel center. However, these overshoots are finally eliminated by other lateral lift forces. Due to the gravity effect, the particles initially close to the channel center prefer migrating to the lower equilibrium position. In addition, the upper equilibrium position is slightly unsymmetrical with the lower one due to gravity effect.

Fig. 8.

Trajectories of a single PM5.0 particle at Rec = 2 and = 830.

Furthermore, we found that the equilibrium positions in the air–particle system are different from those in the liquid–particle system. In a liquid–particle system, generally there are 9 equilibrium points (Abbas et al., 2014, Nakagawa et al., 2015, Zhang et al., 2016): 4 stable points at the vertical and horizontal midlines, 4 unstable points at the diagonal lines and 1 unstable point at the channel center point, as shown in Fig. 9a. They are all symmetrical in both horizontal and vertical directions. However, in the air–particle system there are only 6 equilibrium points (1–6), as shown in Fig. 9b. They are symmetrical only in the horizontal direction, i.e., left to right, by the vertical middle plane (Y* = 0.5), while un-symmetrical in the vertical direction, i.e., the gravity direction or up to bottom. In addition, the two equilibrium points (1–2) at the vertical midlines are unstable, while the other four equilibrium points (3–6) at the vicinity of the diagonal lines are stable. This stability phenomenon will be further confirmed in Section “Effects of the initial particle position” and however, are contrary to those in the liquid–particle system as mentioned above.

Fig. 9.

Equilibrium positions of particles in a square straight microchannel in (a) liquid–particle system and (b) air–particle system.

Effects of the initial particle position

We also found that different initial particle positions significantly influence the particle's path and final equilibrium position. This is because the velocity gradient and the relative velocity at different positions are different, yielding different values of the lift forces. Fig. 10a and b shows the particle movement with initial positions at the midlines and diagonal lines, and the inner zone. The hollow circles represent the initial positions of the particles. We can clearly observe six different equilibrium points, as shown by the solid circles. In the liquid–particle system particle always migrates to the nearby equilibrium point located in the same 1/8 zone. In other words the initial position and the final equilibrium position of the same particle are in the same 1/8 triangle zone, as can be shown in Fig. 2c and previous literatures (Abbas et al., 2014, Chun and Ladd, 2006, Nakagawa et al., 2015). However, in Fig. 10 we can see that some particles have initial and final equilibrium positions positioned at different 1/8 triangle zones. In addition, only the particle initially located in the vertical midline is still focused at the vertical midline. All other particles even ones very close to the vertical midline migrate to the equilibrium positions below the diagonal lines. This indicates that the two equilibrium positions at the vertical midlines are not stable since a particle slightly disturbed away from the vertical midline will not migrate to the two equilibrium positions. The other four equilibrium positions at the vicinity of the diagonal lines are stable because particles eventually migrate to these positions if the initial positions are not at the vertical midlines, as shown in Fig. 10a and b.

Fig. 10.

Migration trajectories affected by the different initial particle positions. (a) Initial positions at the midlines and diagonal lines. (b) Initial positions not at the midlines or diagonal lines. The hollow circles and the solid circles represent the initial positions and the final equilibrium positions of the particles, respectively.

Effects of the particle's density

Fig. 11a and b illustrates the particle's streamwise trajectories affected by different particle densities. They show that particles with a higher density have a larger overshoot and longer streamwise distance to reach their equilibrium positions. This is because heavier particles have higher inertia due to their larger Stokes number depending on density ρ p. However, as the lift force coefficient discussed in Section “Particle's motion and focusing”, the particle's final equilibrium positions are not affected obviously by the particle's density except selecting either the upper one (Z* ≈ 0.754) or the lower one (Z* ≈ 0.241). When particle have a lower density, it behaves approximately like the neutrally buoyant particle in the liquid–particle system, directly migrating to the nearest equilibrium position. The overshoot increases as the particle density increases. If the particle across the horizontal midline to enter another local zone, it will not return to its original equilibrium position and finally reach another equilibrium position.

Fig. 11.

Particle streamwise path with various particle densities at Rec = 2. (a) Initial position is at Z* = 0.15 and (b) initial position is at Z* = 0.85.

Effects of the particle's diameter

Lateral forces acting on the particle originate from the fluid pressure and velocity around the particle. These parameters change as the diameter of the particle varies. Fig. 12 presents the effect of particle's diameter on the fluid streamwise velocity at the cross section corresponding to the particle's center when the particle reaches its equilibrium position. The surface color of the particle depicts its x-velocity. It can be observed that larger particle occupies larger volume and has lower velocity, hence disturbs the fluid flow more significantly. And intuitively larger particle migrates closer to the channel's wall.

Fig. 12.

Effect of the particle's diameter on the equilibrium position at Rec = 2 and = 830. (a) Dp = 2.5 μm, (b) Dp = 5 μm and (c) Dp = 10 μm.

Here, we define a parameter to investigate the effect of the particle's diameter on the equilibrium position by the ratio of the net distance between the particle's surface and the channel wall to the channel height as

| (21) |

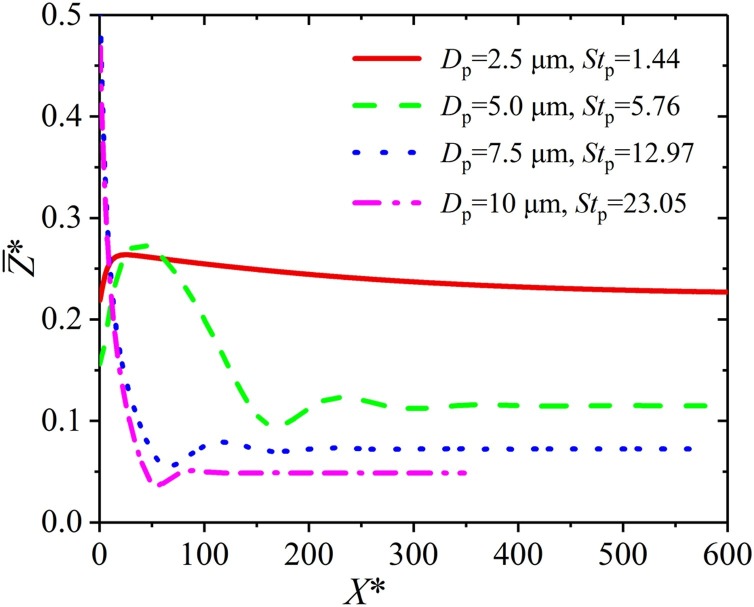

According to the definition, Z* is a dimensionless quantity that increases from zero as the particle moves from the bottom wall to the top wall. Fig. 13 shows the migration process and the final equilibrium position of particles with different diameters. Small particle (D p = 2.5 μm) focuses faster and has the tendency to follow the flow direction. While larger particles migrate to lower positions with an oscillation.

Fig. 13.

Effect of particle's diameter on the streamwise path at Rec = 2 and = 830.

Effects of the fluid Reynolds number

At last, the channel Reynolds number Re c is varied, as shown in Fig. 14 . We can see that larger Re number will cause larger overshoot. This is because the fluid shear rate increases with the increase in Re c. The particle path is oscillating about the final equilibrium position when the Reynolds number is larger than 2. The oscillation shows a pattern of sine function. And its magnitude and duration time increase as the Reynolds number increases. This may because the Saffman force has been dominating when the Reynolds number is high. This lift force is proportional to the shear rate and the magnitude of the relative velocity between the particle and fluid as (Saffman, 1965):

| (22) |

where (u f – u p) is the relative axial velocity component of the particle with respect to the fluid and ∂u f/∂z is the shear rate of the axial velocity component at the vertical direction. The shear rate and relative velocity are relevant to the particle's position Z*. The competition between this Saffman force with other lift force cause the oscillation phenomenon.

Fig. 14.

Effect of the channel Reynolds number Rec on the streamwise path at = 830 and Dp = 5 μm. (a) Initial position is at Z* = 0.15 and (b) initial position is at Z* = 0.85.

Conclusions

The motions of finite size aerosol particles in straight, three-dimensional microchannels with constant rectangular cross-section are investigated by IB-LBM simulations to observe their inertial migration behavior. The initial position, diameter, density of the particle and the fluid Reynolds number are found to be the critical parameters. Conclusions are listed as follows:

-

(1)

The forces exerting on the particle in the air–particle system are more complex than those in the liquid–particle system. The additional Saffman and Mangus forces may dominate when the fluid Reynolds number is relatively high.

-

(2)

Similar to the liquid–particle system, there are two steps during the particle migration process in the air–particle system. The first is the fast migration through the streamwise velocity contour, and the second is the slow migration along the streamwise velocity contour towards the closest equilibrium position.

-

(3)

There are six equilibrium positions. Two unstable equilibrium positions are located at the vertical midlines, while four stable equilibrium positions locate beneath the diagonal lines. They are symmetrical in horizontal direction while unsymmetrical in vertical direction due to gravity effect.

-

(4)

Particles have an overshoot prior to reach their equilibrium positions, and the degree of this overshoot increases as the particle's diameter and density increase.

-

(5)

The initial position of the particle affects the migration trajectory and the final equilibrium positions.

-

(6)

High Reynolds number can cause particle oscillation near the final equilibrium position.

Conflicts of interest

The authors declare that there is no conflict of interests regarding the publication of this article.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NSFC) (Grant Nos. 51876075, 51876076) and the Foundation of State Key Laboratory of Coal Combustion (Grant No. FSKLCCA1802). The author Maoqiang Jiang was also supported by the Chinese CSC scholarship.

References

- Abbas M., Magaud P., Gao Y., Geoffroy S. Migration of finite sized particles in a laminar square channel flow from low to high Reynolds numbers. Physics of Fluids. 2014;26:123301. [Google Scholar]

- Aidun C.K., Clausen J.R. Lattice-Boltzmann method for complex flows. Annual Review of Fluid Mechanics. 2009;42:439–472. [Google Scholar]

- Akhatov I.S., Hoey J.M., Swenson O.F., Schulz D.L. Aerosol flow through a long micro-capillary: Collimated aerosol beam. Microfluidics & Nanofluidics. 2008;5:215–224. [Google Scholar]

- Akhatov I.S., Hoey J.M., Swenson O.F., Schulz D.L. Aerosol focusing in micro-capillaries: Theory and experiment. Journal of Aerosol Science. 2008;39:691–709. [Google Scholar]

- Amini H., Lee W., Di Carlo D. Inertial microfluidic physics. Lab on a Chip. 2014;14:2739–2761. doi: 10.1039/c4lc00128a. [DOI] [PubMed] [Google Scholar]

- Amini H., Sollier E., Weaver W.M., Carlo D.D. Intrinsic particle-induced lateral transport in microchannels. Proceedings of the National Academy of Sciences of the United States of America. 2012;109:11593. doi: 10.1073/pnas.1207550109. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Asmolov E.S., Dubov A.L., Nizkaya T.V., Harting J., Vinogradova O.I. Inertial focusing of finite-size particles in microchannels. Journal of Fluid Mechanics. 2018;840:613–630. [Google Scholar]

- Barkla H.M., Auchterlonie L.J. The Magnus or Robins effect on rotating spheres. Journal of Fluid Mechanics. 1971;47:437–447. [Google Scholar]

- Bian X., Lan Y., Wang B., Zhang Y.S., Liu B., Yang P., et al. Microfluidic air sampler for highly efficient bacterial aerosol collection and identification. Analytical Chemistry. 2016;88:11504–11512. doi: 10.1021/acs.analchem.6b02708. [DOI] [PubMed] [Google Scholar]

- Brennen C.E. Cambridge University Press; 2005. Fundamentals of multiphase flow. [Google Scholar]

- Bruus H. Oxford University Press; 2008. Theoretical microfluidics. [Google Scholar]

- Chen S., Doolen G.D. Lattice Boltzmann method for fluid flows. Annual Review of Fluid Mechanics. 1998;30:329–364. [Google Scholar]

- Chin C.D., Laksanasopin T., Cheung Y.K., Steinmiller D., Linder V., Parsa H., et al. Microfluidics-based diagnostics of infectious diseases in the developing world. Nature Medicine. 2011;17:1015. doi: 10.1038/nm.2408. [DOI] [PubMed] [Google Scholar]

- Chun B., Ladd A.J.C. Inertial migration of neutrally buoyant particles in a square duct: An investigation of multiple equilibrium positions. Physics of Fluids. 2006;18:031704. [Google Scholar]

- Deng R., Zhang X., Smith K.A., Wormhoudt J., Lewis D.K., Freedman A. Focusing particles with diameters of 1 to 10 microns into beams at atmospheric pressure. Aerosol Science and Technology. 2008;42:899–915. [Google Scholar]

- Di Carlo D., Edd J.F., Humphry K.J., Stone H.A., Toner M. Particle segregation and dynamics in confined flows. Physical Review Letters. 2009;102:094503. doi: 10.1103/PhysRevLett.102.094503. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Douwes J., Thorne P., Pearce N., Heederik D. Bioaerosol health effects and exposure assessment: Progress and prospects. The Annals of Occupational Hygiene. 2003;47:187–200. doi: 10.1093/annhyg/meg032. [DOI] [PubMed] [Google Scholar]

- Fan B., McFarland A.R., Anand N.K. Characterization of the aerosol particle lift force. Journal of Aerosol Science. 1992;23:379–388. [Google Scholar]

- Guo Z., Zheng C., Shi B. Discrete lattice effects on the forcing term in the lattice Boltzmann method. Physical Review E. 2002;65:046308. doi: 10.1103/PhysRevE.65.046308. [DOI] [PubMed] [Google Scholar]

- Guo Z., Zheng C., Shi B. Non-equilibrium extrapolation method for velocity and pressure boundary conditions in the lattice Boltzmann method. Chinese Physics. 2002;11:366. [Google Scholar]

- Haddadi H., Di Carlo D. Inertial flow of a dilute suspension over cavities in a microchannel. Journal of Fluid Mechanics. 2017;811:436–467. [Google Scholar]

- Han E. Loop-mediated isothermal amplification test for the molecular diagnosis of malaria. Expert Review of Molecular Diagnostics. 2013;13:205–218. doi: 10.1586/erm.12.144. [DOI] [PubMed] [Google Scholar]

- Hoey J.M., Lutfurakhmanov A., Schulz D.L., Akhatov I.S. A review on aerosol-based direct-write and its applications for microelectronics. Journal of Nanotechnology. 2012;2012:22. [Google Scholar]

- Hong S.C., Kang J.S., Lee J.E., Kim S.S., Jung J.H. Continuous aerosol size separator using inertial microfluidics and its application to airborne bacteria and viruses. Lab on a Chip. 2015;15:1889–1897. doi: 10.1039/c5lc00079c. [DOI] [PubMed] [Google Scholar]

- Jebakumar A.S., Premnath K.N., Abraham J. Lattice Boltzmann method simulations of Stokes number effects on particle trajectories in a wall-bounded flow. Computers & Fluids. 2016;124:208–219. [Google Scholar]

- Jiang D., Huang D., Zhao G., Tang W., Xiang N. Numerical simulation of particle migration in different contraction–expansion ratio microchannels. Microfluidics and Nanofluidics. 2018;23 [Google Scholar]

- Jiang D., Tang W., Xiang N., Ni Z. Numerical simulation of particle focusing in a symmetrical serpentine microchannel. RSC Advances. 2016;6:57647–57657. [Google Scholar]

- Jiang M., Li J., Liu Z. 2020. Efficient implementation of immersed boundary-lattice Boltzmann method for massive particle-laden flows Part I: Serial computing. (submitted for publication) [Google Scholar]

- Jiang M., Li J., Liu Z. 2020. Efficient implementation of immersed boundary-lattice Boltzmann method for massive particle-laden flows Part II: MPI parallel computing. (submitted for publication) [Google Scholar]

- Jiang M., Liu Z. A boundary thickening-based direct forcing immersed boundary method for fully resolved simulation of particle-laden flows. Journal of Computational Physics. 2019;390:203–231. [Google Scholar]

- Jiang M., Qian S., Liu Z. Fully resolved simulation of single-particle dynamics in a microcavity. Microfluidics and Nanofluidics. 2018;22:144. [Google Scholar]

- Jiang M., Zhang R., Liu Z. Direct forcing immersed boundary-lattice Boltzmann coupling method for solving fluid structure interaction with complex boundary. Journal of Engineering Thermophysics. 2018;39 [Google Scholar]

- Jing W., Jiang X., Zhao W., Liu S., Cheng X., Sui G. Microfluidic platform for direct capture and analysis of airborne Mycobacterium tuberculosis. Analytical Chemistry. 2014;86:5815–5821. doi: 10.1021/ac500578h. [DOI] [PubMed] [Google Scholar]

- Jing W., Zhao W., Liu S., Li L., Tsai C.-T., Fan X., et al. Microfluidic device for efficient airborne bacteria capture and enrichment. Analytical Chemistry. 2013;85:5255–5262. doi: 10.1021/ac400590c. [DOI] [PubMed] [Google Scholar]

- Kim J., Lee J., Wu C., Nam S., Di Carlo D., Lee W. Inertial focusing in non-rectangular cross-section microchannels and manipulation of accessible focusing positions. Lab on a Chip. 2016;16:992–1001. doi: 10.1039/c5lc01100k. [DOI] [PubMed] [Google Scholar]

- Ladd A.J.C. Numerical simulations of particulate suspensions via a discretized Boltzmann equation. Part 1. Theoretical foundation. Journal of Fluid Mechanics. 1994;271:285–309. [Google Scholar]

- Ladd A.J.C. Numerical simulations of particulate suspensions via a discretized Boltzmann equation. Part 2. Numerical results. Journal of Fluid Mechanics. 1994;271:311–339. [Google Scholar]

- Lashgari I., Ardekani M.N., Banerjee I., Russom A., Brandt L. Inertial migration of spherical and oblate particles in straight ducts. Journal of Fluid Mechanics. 2017;819:540–561. [Google Scholar]

- Lee K.-S., Hwang T.-H., Kim S.-H., Kim S.H., Lee D. Numerical simulations on aerodynamic focusing of particles in a wide size range of 30 nm–10 μm. Aerosol Science and Technology. 2013;47:1001–1008. [Google Scholar]

- Liu C., Hu G., Jiang X., Sun J. Inertial focusing of spherical particles in rectangular microchannels over a wide range of Reynolds numbers. Lab on a Chip. 2015;15:1168–1177. doi: 10.1039/c4lc01216j. [DOI] [PubMed] [Google Scholar]

- Liu Q., Zhang Y., Jing W., Liu S., Zhang D., Sui G. First airborne pathogen direct analysis system. Analyst. 2016;141:1637–1640. doi: 10.1039/c5an02367j. [DOI] [PubMed] [Google Scholar]

- Lu L., Liu X., Li T., Wang L., Ge W., Benyahia S. Assessing the capability of continuum and discrete particle methods to simulate gas-solids flow using DNS predictions as a benchmark. Powder Technology. 2017;321:301–309. [Google Scholar]

- Lu X., Liu C., Hu G., Xuan X. Particle manipulations in non-Newtonian microfluidics: A review. Journal of Colloid and Interface Science. 2017;500:182–201. doi: 10.1016/j.jcis.2017.04.019. [DOI] [PubMed] [Google Scholar]

- Lu Z., He Y., Yu B., Hu X. Harmful effects of airborne dust diffused from ceramic tiles during home decoration. Powder Technology. 2014;267:86–94. [Google Scholar]

- Martel J.M., Toner M. Inertial focusing in microfluidics. Annual Review of Biomedical Engineering. 2014;16:371–396. doi: 10.1146/annurev-bioeng-121813-120704. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Maxey M. Simulation methods for particulate flows and concentrated suspensions. Annual Review of Fluid Mechanics. 2017;49:171–193. [Google Scholar]

- Mazzoli A., Favoni O. Particle size, size distribution and morphological evaluation of airborne dust particles of diverse woods by Scanning Electron Microscopy and image processing program. Powder Technology. 2012;225:65–71. [Google Scholar]

- Metcalf A.R., Narayan S., Dutcher C.S. A review of microfluidic concepts and applications for atmospheric aerosol science. Aerosol Science and Technology. 2018;52:310–329. [Google Scholar]

- Mittal R., Iaccarino G. Immersed boundary methods. Annual Review of Fluid Mechanics. 2005;37:239–261. [Google Scholar]

- Nakagawa N., Yabu T., Otomo R., Kase A., Makino M., Itano T., et al. Inertial migration of a spherical particle in laminar square channel flows from low to high Reynolds numbers. Journal of Fluid Mechanics. 2015;779:776–793. [Google Scholar]

- Nguyen N.Q., Ladd A.J.C. Lubrication corrections for lattice-Boltzmann simulations of particle suspensions. Physical Review E. 2002;66:046708. doi: 10.1103/PhysRevE.66.046708. [DOI] [PubMed] [Google Scholar]

- Peskin C.S. The immersed boundary method. Acta Numerica. 2002;11:479–517. [Google Scholar]

- Pietrowska M., Marczak L., Polanska J., Behrendt K., Nowicka E., Walaszczyk A., et al. Mass spectrometry-based serum proteome pattern analysis in molecular diagnostics of early stage breast cancer. Journal of Translational Medicine. 2009;7:60. doi: 10.1186/1479-5876-7-60. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Qian Y.H., D’Humières D., Lallemand P. Lattice BGK models for Navier–Stokes equation. Europhysics Letters (EPL) 1992;17:479–484. [Google Scholar]

- Saffman P.G. The lift on a small sphere in a slow shear flow. Journal of Fluid Mechanics. 1965;22:385–400. [Google Scholar]

- Schaap A., Chu W.C., Stoeber B. Transport of airborne particles in straight and curved microchannels. Physics of Fluids. 2012;24:083301. [Google Scholar]

- Su J., Chen X., Hu G. Inertial migrations of cylindrical particles in rectangular microchannels: Variations of equilibrium positions and equivalent diameters. Physics of Fluids. 2018;30:032007. [Google Scholar]

- Sui G., Cheng X. Microfluidics for detection of airborne pathogens: What challenges remain? Bioanalysis. 2014;6:5–7. doi: 10.4155/bio.13.287. [DOI] [PubMed] [Google Scholar]

- Sun D., Bo Z. Numerical simulation of hydrodynamic focusing of particles in straight channel flows with the immersed boundary-lattice Boltzmann method. International Journal of Heat and Mass Transfer. 2015;80:139–149. [Google Scholar]

- Sun D., Jiang D., Xiang N., Chen K., Ni Z. An immersed boundary-lattice Boltzmann simulation of particle hydrodynamic focusing in a straight microchannel. Chinese Physics Letters. 2013;30:74702. [Google Scholar]

- Sun D., Wang Y., Dong A., Sun B.-D. A three-dimensional quantitative study on the hydrodynamic focusing of particles with the immersed boundary–Lattice Boltzmann method. International Journal of Heat and Mass Transfer. 2016;94:306–315. [Google Scholar]

- Tavakoli F., Mitra S.K., Olfert J.S. Aerosol penetration in microchannels. Journal of Aerosol Science. 2011;42:321–328. [Google Scholar]

- Wu Z., Chen Y., Wang M., Chung A.J. Continuous inertial microparticle and blood cell separation in straight channels with local microstructures. Lab on a Chip. 2016;16:532–542. doi: 10.1039/c5lc01435b. [DOI] [PubMed] [Google Scholar]

- Xiang N., Dai Q., Ni Z. Multi-train elasto-inertial particle focusing in straight microfluidic channels. Applied Physics Letters. 2016;109:134101. [Google Scholar]

- Xiong Q., Li B., Zhou G., Fang X., Xu J., Wang J., et al. Large-scale DNS of gas–solid flows on Mole-8.5. Chemical Engineering Science. 2012;71:422–430. [Google Scholar]

- Yin H., Wan H., Mason A.J. Separation and electrochemical detection platform for portable individual PM2.5 monitoring. 2017 IEEE International Symposium on Circuits and Systems (ISCAS) 2017:1–4. [Google Scholar]

- Yu F., Li Y., Li M., Tang L., He J.-J. DNAzyme-integrated plasmonic nanosensor for bacterial sample-to-answer detection. Biosensors and Bioelectronics. 2017;89:880–885. doi: 10.1016/j.bios.2016.09.103. [DOI] [PubMed] [Google Scholar]

- Yuan D., Zhao Q., Yan S., Tang S.-Y., Alici G., Zhang J., et al. Recent progress of particle migration in viscoelastic fluids. Lab on a Chip. 2018;18:551–567. doi: 10.1039/c7lc01076a. [DOI] [PubMed] [Google Scholar]

- Zhang D., Bi H., Liu B., Qiao L. Detection of pathogenic microorganisms by microfluidics based analytical methods. Analytical Chemistry. 2018;90:5512–5520. doi: 10.1021/acs.analchem.8b00399. [DOI] [PubMed] [Google Scholar]

- Zhang J., Yan S., Yuan D., Alici G., Nguyen N.-T., Ebrahimi Warkiani M., et al. Fundamentals and applications of inertial microfluidics: a review. Lab on a Chip. 2016;16:10–34. doi: 10.1039/c5lc01159k. [DOI] [PubMed] [Google Scholar]