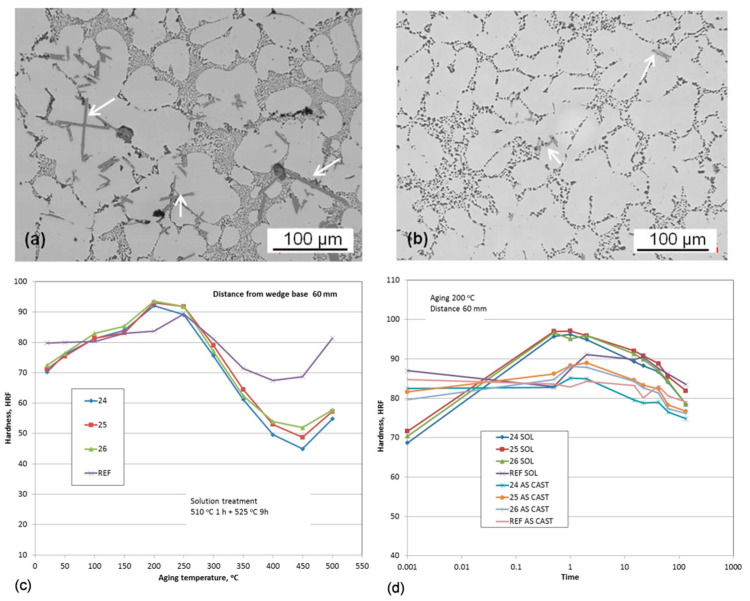

Figure 22.

Microstructure of the Al7Si1Cu0.5Mg alloy modified with 0.47 wt.% Zr, 0.21 wt.% Ti, 0.30 wt.% V in as-cast condition (a) and after T6 heat treatment (solutionizing 510 °C: 0.5 h + 525 °C, 4.5 h water quench; aging 200 °C, 1 h air cooling). Arrows indicate coarse phases containing transition metals Ti−Zr−V (b). Effect of aging temperature (c) and time (d) on hardness for various additions of transition metals. Figure legend: (24) 0.14 wt.% Zr, 0.14 wt.% Ti, 0.22 wt.% V; (25) 0.42 wt.% Zr, 0.18 wt.% Ti, 0.17 wt.% V; (26) 0.47 wt.% Zr, 0.21 wt.% Ti, 0.30 wt.% V; (REF) A380 alloy.