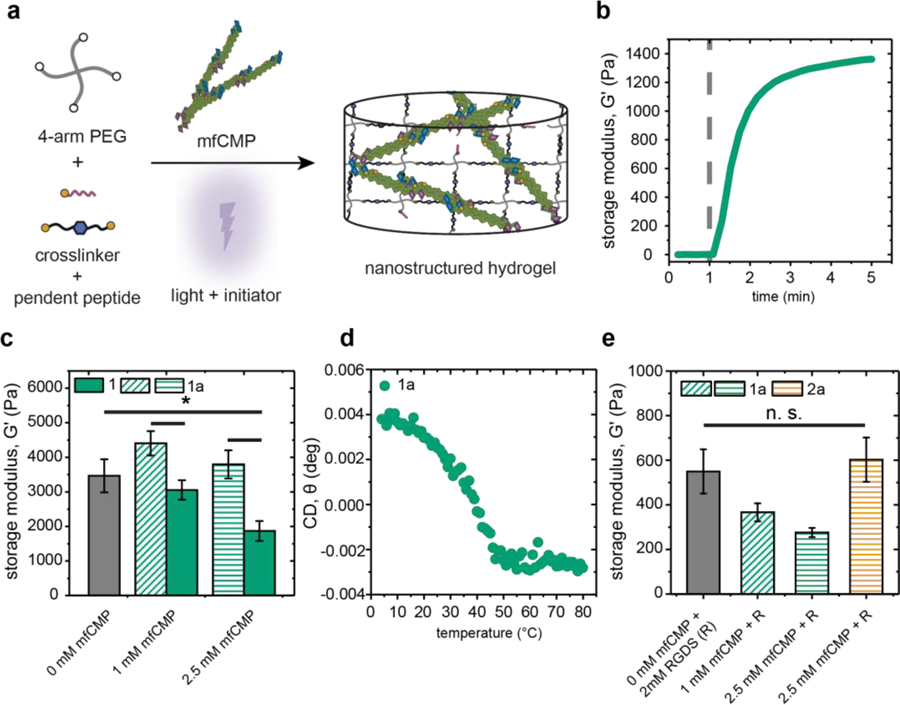

Fig. 3:

Mechanical properties of nanostructured hydrogels containing mfCMPs. a) Schematic of approach for incorporation of assembled mfCMPs within hydrogels using K(alloc) handle that is orthogonal to assembly: mfCMPs were assembled in solution for 48 h, diluted into a hydrogel precursor solution, and immediately irradiated in situ to form robust, nanostructured hydrogels. b) In situ oscillatory rheometry was used to monitor the rapid formation of these hydrogels (dashed gray line indicates when irradiation commenced; here, hydrogel formed with 2.5 mM mfCMP-1a as representative example), and their resulting mechanical properties compared. Hydrogels formed with c) increasing amounts of mfCMPs with or without an alloc group (mfCMP-1a or mfCMP-1, respectively). d) CD on an in situ hydrogel containing 2.5 mM mfCMP-1a to determine the melting temperature of assembled mfCMPs within the covalently crosslinked network. e) Moduli of hydrogels formed with mfCMPs and integrin binding peptide RGDS equilibrated in DPBS at 37 °C, which were the formulations used in 3D cell culture studies. The data shown illustrate the mean with error bars showing the standard error (n ≥ 3; * p < 0.05).