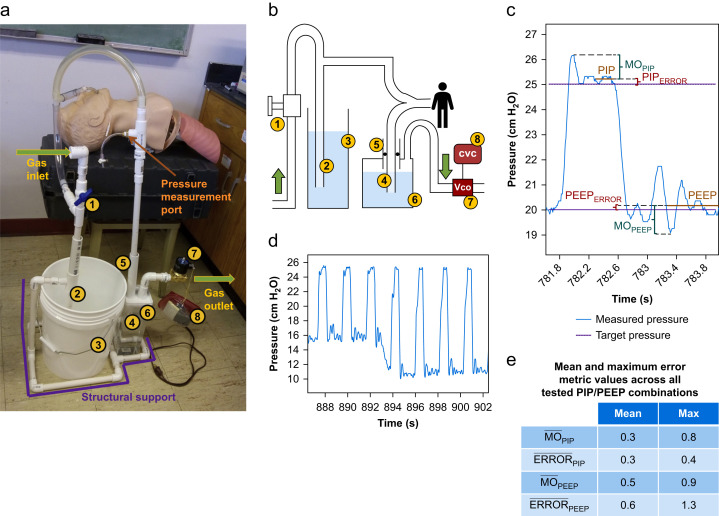

Fig 1.

Low-cost mechanical ventilator design and operation. (a) Prototype constructed of polyvinyl chloride plumbing and common electrical components; (b) schematic with adjustable flow regulator: (1) 0.5 inch manually-controlled ball valve; peak inspiratory pressure (PIP) control assembly: (2) 57.5 cm long×0.5 inch diameter (15.8 mm ID) pipe, marked at 5 cm intervals, with open lower end submerged in (3) open reservoir; and PEEP control assembly: (4) 60 cm×0.5 inch pipe, marked at 5 cm intervals, inserted through (5) a concentric 25 cm×1 inch (26.6 mm ID) outer pipe attached with air-tight connection to the top of (6) transparent closed reservoir. In PEEP control assembly, an O-ring sealed the space between inner (#4) and outer (#5) pipes such that pipe #4 could be raised/lowered to adjust PEEP while the reservoir remained sealed. A tube from the top of the PEEP reservoir led to (6) the cycling outlet valve (Vco), 0.75 inch Brass Electric Solenoid Air Valve (U.S. Solid®, Cleveland, OH, USA) controlled by (7) a cycling valve circuit (CVC) that generated a square wave signal. (c) Variables of interest. (d) Pressure trace for the transition between two settings: PIP of 25 cm H2O and PEEP from 15 to 10 cm H2O. (e) Aggregated errors. MO, maximum overshoot.