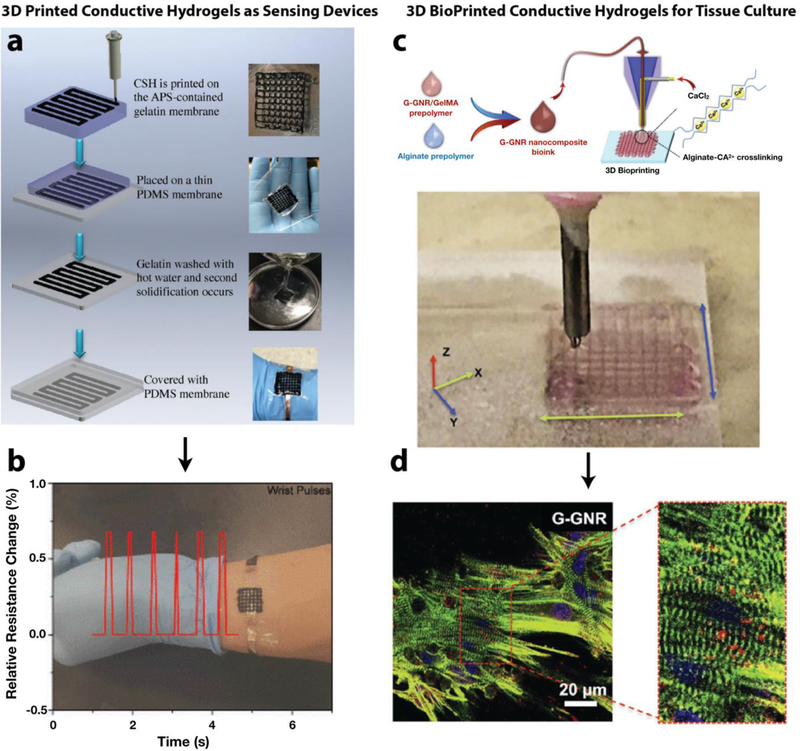

Figure 5. 3D printing of conductive hydrogels for different biomedical applications.

Pressure sensors were fabricated by 3D printing a conductive self-healing (CSH) hydrogel composed of PPy-grafted chitosan and poly(acrylic acid), and coating them with a thin layer of PDMS (a). When applied to the wrist, the sensor could detect blood flow pulses in the veins below the skin in real-time (b). [146] Hydrogel prepolymer solution containing sodium alginate, gold nanorods, and GelMA was bioprinted via a co-axial nozzle, in which the alginate prepolymer solution in the core was crosslinked by calcium ions flown in the sheath (c). Lattice-like structures could be printed, and hydration was maintained by the continuous flow of the aqueous sheath solution. Cardiomyocytes printed in these structures expressed higher levels of Cxn43 cardiac junction protein and exhibited higher contraction rates compared to controls (d). [152]

Sources:

[146], [152] Copyright 2018, 2017, respectively. Reproduced with permission from John Wiley and Sons Inc.