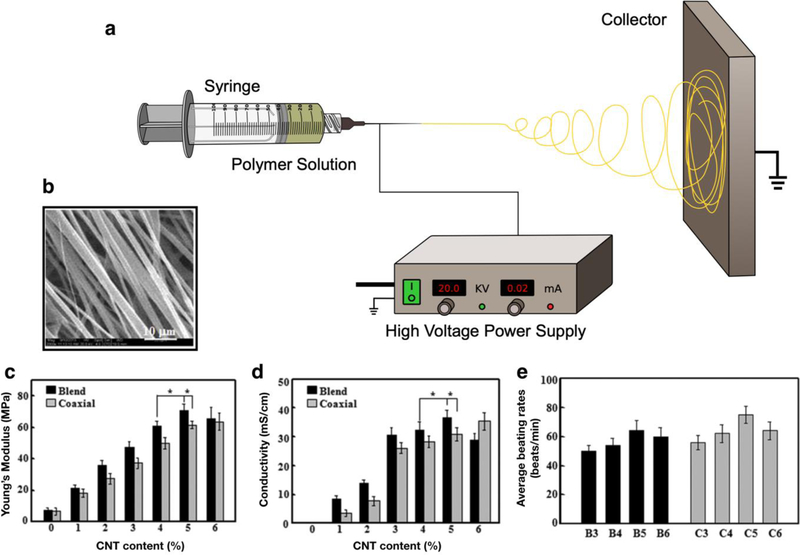

Figure 6. Electrospinning of ECHs for different biomedical applications.

Schematic for an electrospinning set up consists of a polymer dissolved in solvent being injected out of a metal nozzle (a). A high voltage power supply is connected to a metal nozzle and a metal collector creating an electrical field. A polymeric solution is then slowly pumped out of the syringe and spun onto the metal collector. Representative SEM image of a blend electrospun PELA/CNT fibrous scaffold with a 5% CNT concentration showing high alignment of fibers and 2 µm fiber diameter (b). Mechanical study of electrospun PELA/CNTs demonstrated that ECHs fabricated with higher concentrations of CNTs resulted in a higher Young’s modulus (c). Electrical evaluation of electrospun ECHs showed that these fibrous scaffolds exhibited higher conductivity when fabricated with a higher concentration of CNTs in both blended and coaxial electrospun PELA/CNT scaffolds (d). Beating rate of CMs when seeded on PELA/CNT fibrous scaffolds and cultured for 710 days. The beating rate for ECHs coaxially electrospun with a 5% CNT concentration (C5) achieved an average beating rate of 70–80 times/min, which is similar to that rate of CMs seeded on other non-conductive hydrogels (e). [171], Copyright 2016. Reproduced with permission from Elsevier Inc.