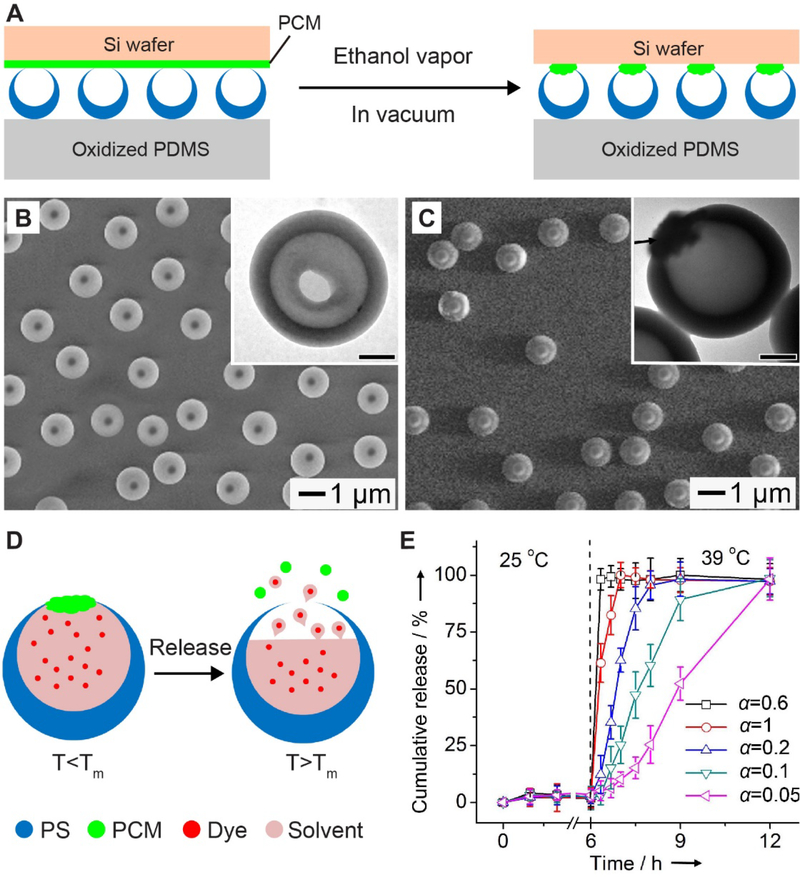

Figure 11.

Corking the opening of hollow particles. (A) Schematic illustration showing the process of corking the openings of PS hollow particles with PCM. (B, C) SEM images of PS hollow particles (B) before and (C) after corking with PCM. The insets are the corresponding TEM images (scale bars: 300 nm). (D) Schematic illustration showing PCM serving as the cork of a PS hollow particle for controlled release of payloads in response to temperature rise. Tm stands for the melting temperature of PCM. (E) Release profiles of the payloads from the particles corked with a binary mixture of PCM made with 1-tetradecanol and lauric acid. The volumetric ratio (α) of 1-tetradecanol to lauric acid was tuned from 0.05:1 to 1:1, which could result in the changes of the melting temperature of the PCM. The scale bars in the insets are 300 nm. Reproduced with permission.[129] Copyright 2013, Wiley-VCH.