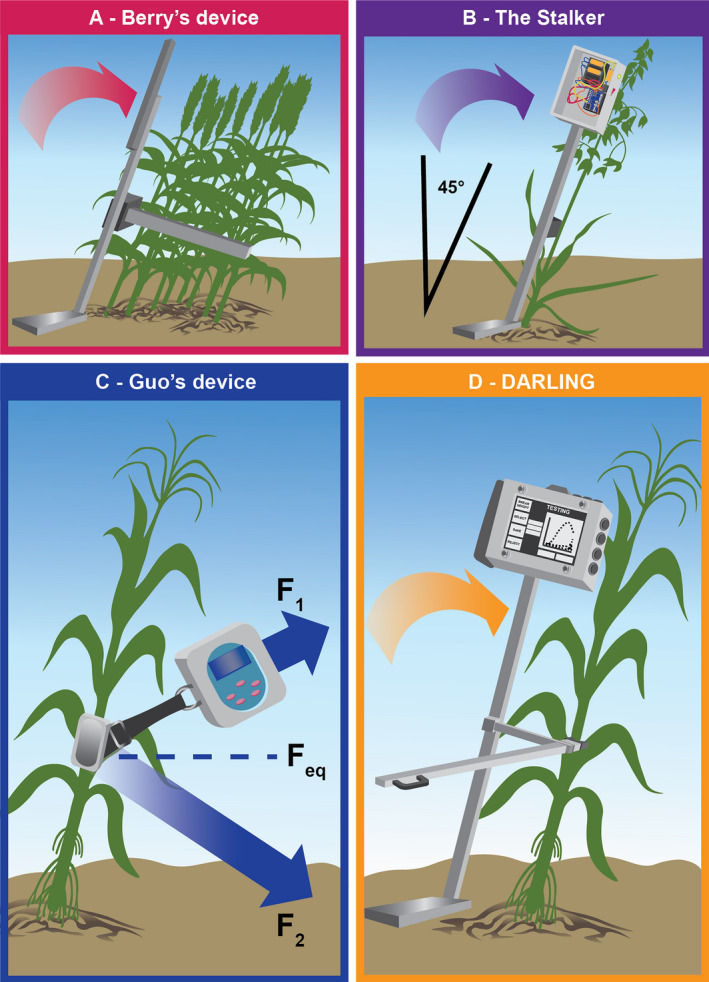

Figure 3.

Devices for measuring stalk bending strength. (A) Berry’s device was developed to study winter wheat stalk lodging and consists of a hand‐held force meter with a load cell attached to a push bar that measures the resistance force required to push over multiple plants. (B) An updated version of this device, called the Stalker, was developed for small grains (wheat, oat, and barley). The Stalker reduced the weight of Berry’s device and introduced some automation, i.e., the device is pushed forward until a preset 45°, and then the force‐rotation data are continuously recorded until the test is ended by the operator. (C) Guo’s device features a hand‐held two‐component circuit block system and measures the forces required to bend maize stalks across a set of discrete angles. One component, a controller module, contains a strain sensor, single‐axis angle sensor, microcontroller, power supply module, a signal acquisition circuit, and a radio frequency transceiver. The second component consists of another radio frequency transceiver and single‐axis sensor. The two components are connected by a rigid belt, and the controller is pulled to discrete angles (represented as F1 and F2) to measure the maximum equivalent force (Feq), which is used to assess stalk lodging resistance. (D) DARLING was developed to assess stalk biomechanics in larger cereal crops and more closely recreate natural failure patterns during stalk lodging. DARLING consists of a vertical support with a control box and digital display mounted at the top, a horizontal footplate attached by a hinge at the base, and an adjustable‐height load cell attached to the vertical support. Plants can be non‐destructively bent within the linear‐elastic range of the material to obtain flexural stiffness or displaced until failure; the maximum applied bending strength is then recorded.