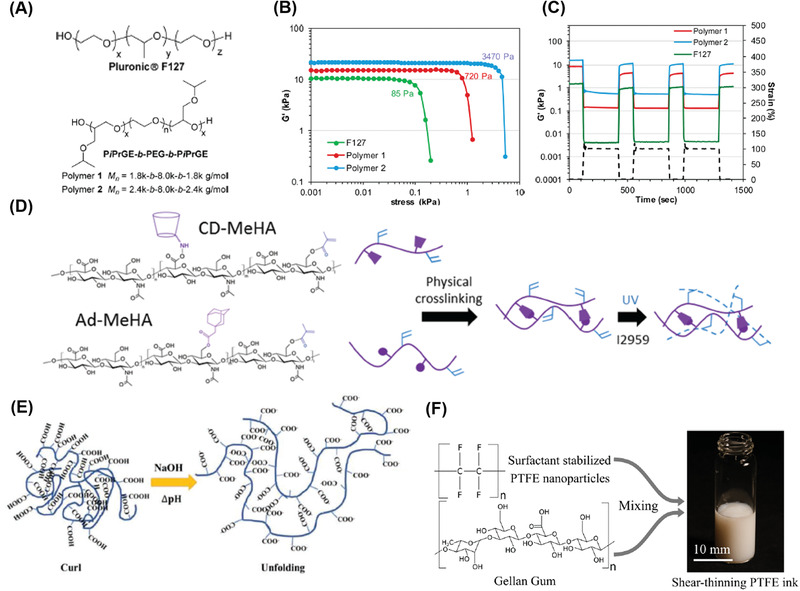

Figure 3.

Examples of material design approaches toward A–E) printable hydrogels and F) PFTE via DIW. A–C) Hydrophobically crosslinked hydrogel. A) Chemical representations for PiPrGE‐b‐PEG‐b‐PiPrGE triblock copolymers and F127. Reproduced with permission.[ 82 ] Copyright 2015, American Chemical Society. B) Storage modulus versus stress showing the corresponding yield stress for different polymer ink formulations. C) Cyclic shear‐thinning experiment of the polymers in (A). D) An example of double crosslinked hydrogels for 3D printing for improved resolution and stability: Hyaluronic acid modified with both methacrylates, guest and host molecules. Ad–MeHA and CD–MeHA macromers crosslink by both physical bonding upon mixing and through a secondary crosslinking of methacrylates with UV light exposure.[ 86 ] Copyright 2015, John Wiley and Sons. E) Schematic of the fluid‐to‐gel transition of carbomer enabled ink through increasing molecular interactions upon pH change. Reproduced with permission.[ 87 ] Copyright 2019, John Wiley and Sons. F) Schematics of the molecular structures and processes developed to 3D‐print PTFE structures. Reproduced with permission.[ 88 ] Copyright 2019, American Chemical Society.