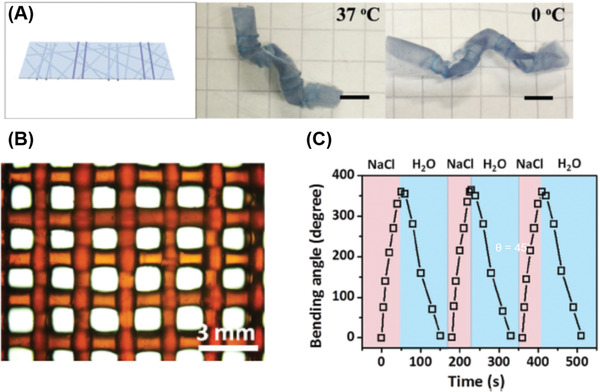

Figure 10.

Introducing stresses into a printed 2D structure using extrusion‐based 3D printing. A) Irreversible formation of folded tube with sites for thermo‐actuations by printing poly(N‐isopropyl acrylamide) (PNIPAm) hydrogel lines on both sides of the electrospun substrate (scale bars: 5 mm). Reproduced with permission.[ 218 ] Copyright 2016, John Wiley and Sons. B) Micrograph of the two‐layer printed grid of poly(acrylic acid‐co‐acrylamide) hydrogel fabricated by 3D printing.[ 111 ] C) Variation of bending angles of the printed poly(acrylic acid‐co‐acrylamide) hydrogel constructs with time after cyclic incubation in 4 m saline solution and pure water.