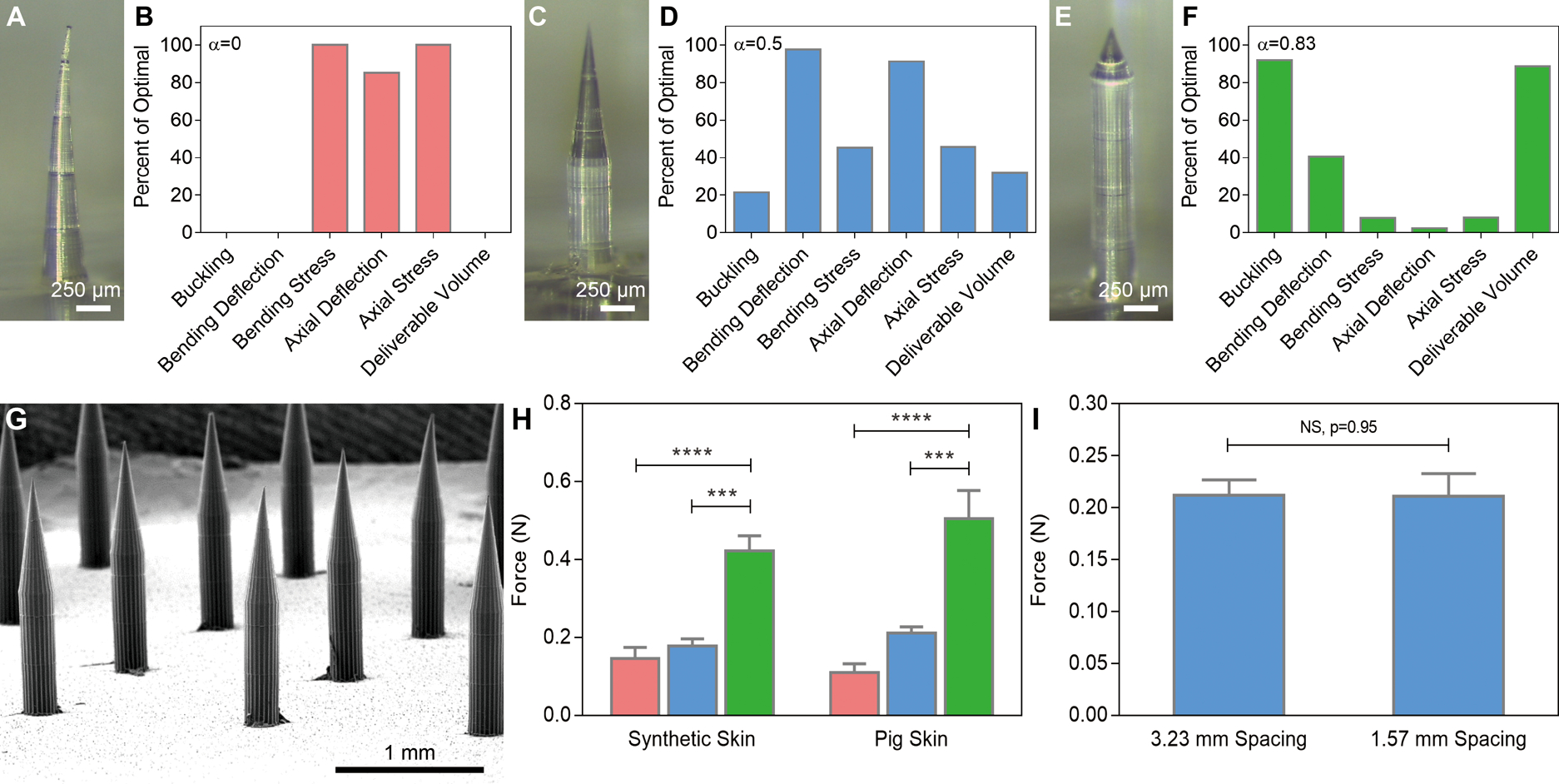

Fig. 3. Microneedle modeling, fabrication, and evaluation.

Optical images of microneedles and finite element analysis data of (A-B) a conical needle 1500 μm in height and 300 μm at its base; (C-D) a microneedle 300 μm at its base with a 750 μm cone atop a 750 μm cylinder; and (E-F) a microneedle 300 μm at its base with a 250 μm cone atop a 1250 μm cylinder. (G) SEM image of a dissolvable microneedle array based on the geometry shown in (C). (H) Ex vivo penetration force per needle based on microneedle geometry, n=3, ***P < 0.001, ****P < 0.0001 (one-way ANOVA with Tukey’s multiple comparisons). (I) Spacing-independent penetration force requirements in pig skin ex vivo (Student’s t-test). In (B, D, F), zero and one hundred represent the worst and best values, respectively, for each parameter for α between 0 and 1.