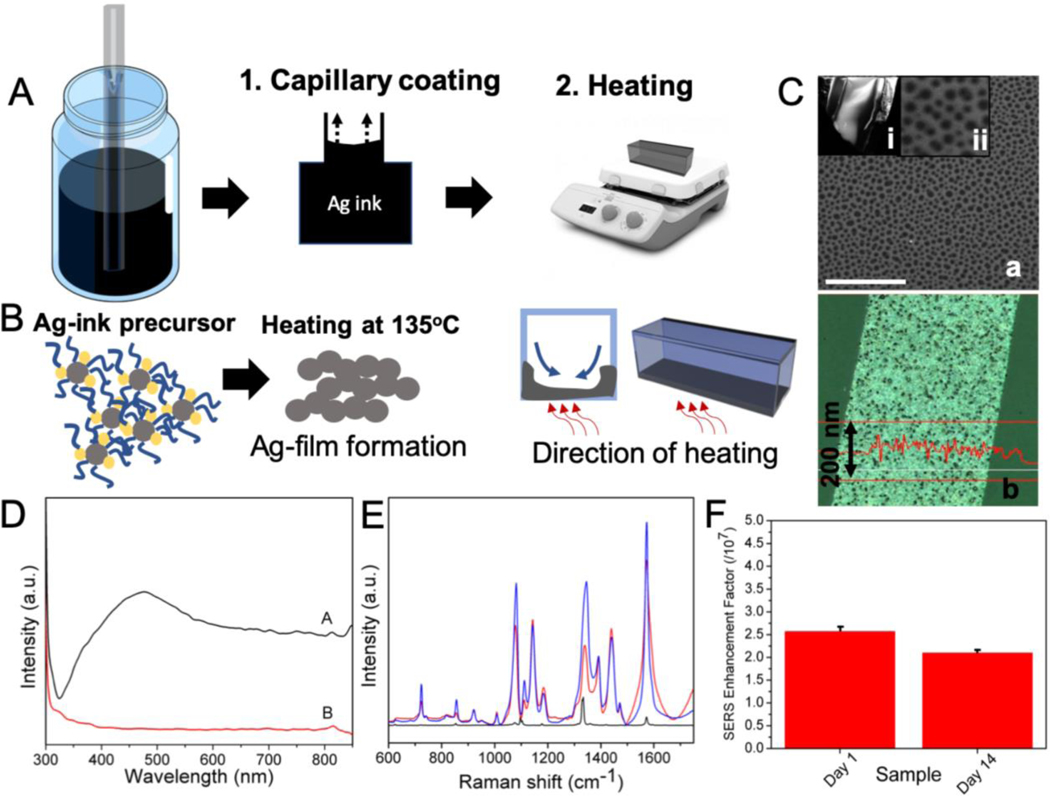

Figure 3.

(A) Schematic outlining the steps involved in the formation of silver nanoparticle coating in the SERS-in-a-capillary substrate. The steps involved are: coating of the capillary tube with the Ag- ink precursor; and heating. (B) The process of formation of the Ag-film involves the thermal degradation of the Ag-ink precursor. The direction of heating determines the side of the capillary that gets coated with the Ag-film. (C) (a) FESEM images of the Ag-film inside the capillary tube through an obliquely broken edge (i). The Ag-film shows nanohole arrays of around 50–100 nm in diameter (ii). Scale bar shown in SEM image corresponds to 1 micron. (b) The optical profilometry image of the Ag-film showing an average thickness of 115 nm. (D) The UV-vis spectra of the capillary coated with Ag-film (black) and Ag-ink (red) shows the presence and absence of surface plasmon peak at ca. 475 nm for the Ag-film and the Ag-ink, respectively. (E) Averaged SERS spectra of 4-NTP (1 × 10−4 M) acquired from freshly prepared SERS-in-a-capillary substrates (blue) and substrates aged for two weeks (red). Raman spectrum of 4-NTP in powder form is shown in black. (F) The calculated SERS enhancement factors corresponding to the freshly prepared and aged (2 weeks) SERS-in-a-capillary substrates.