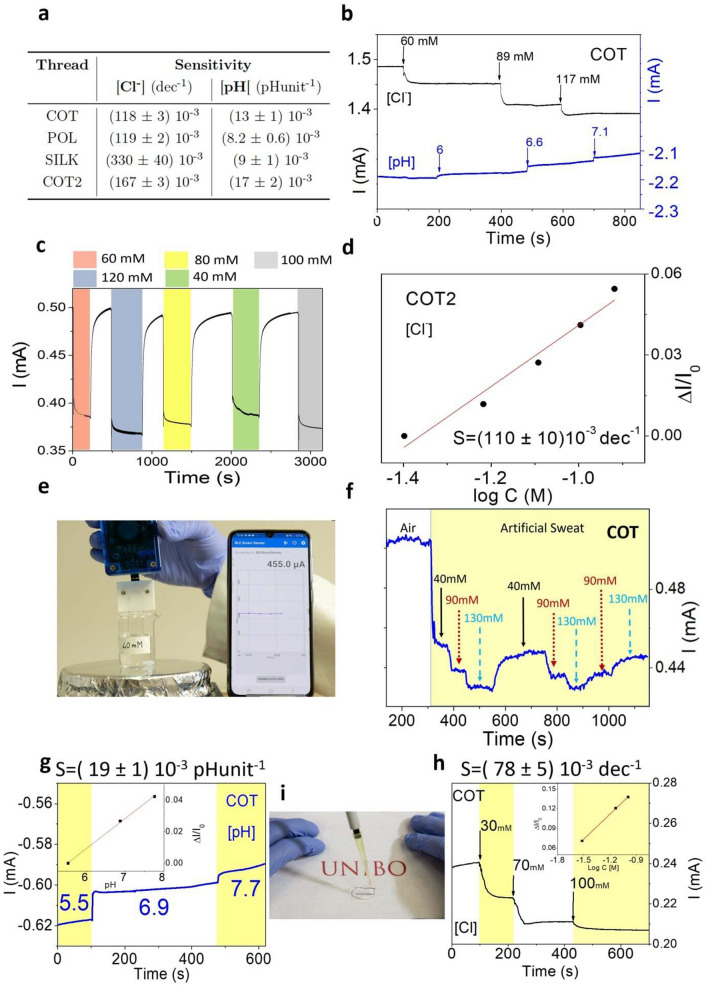

Figure 6.

Characterization in artificial sweat and applications: (a) Table reporting the sensitivities of the single thread characterization in 10 mL of Artificial Sweat. For the Cl− and pH thread sensors the current is normalised with the I0 value acquired at 40 mM and 5.5 pH level, respectively. (b) Interference test in 10 mL of Artificial Sweat to simulate real-life condition using COT threads. The sensitivities values in artificial sweat are (141 ± 8) 10–3 dec−1 and (18 ± 2) 10–3 pH unit−1 for Cl− and pH sensors, respectively. (c) Random immersion of the COT Cl− sensor in chloride ion solutions having different concentrations. The white parts indicate the thread sensor in air, while the coloured parts point out the thread immersed in liquid. (d) Calibration plot of the COT thread as Cl− sensor after random additions while using the wireless-portable read-out electronics. (e) Test of Cl− concentration in artificial sweat with a custom wireless data-reader. (f) Plot of the signal shown on a smartphone after consecutive addition of 3 M KCl (40 mM, 90 mM, 130 mM). The arrows indicate the interval in which there is a variation in the Cl− concentration. The reversibility test has been carried out by bringing the Cl− concentration back to the starting value. Current signal, calibration plot and sensitivity for (g) pH sensor and (h) Cl− sensor. The threads are immersed in 1 mL of artificial sweat an 1 M KOH and 3 M KCl were used to change the pH level and Cl concentration, respectively. (i) Example of a sensorized T-shirt for hydration and pH monitoring used to characterize the textile thread sensors in conditions similar to the real ones.