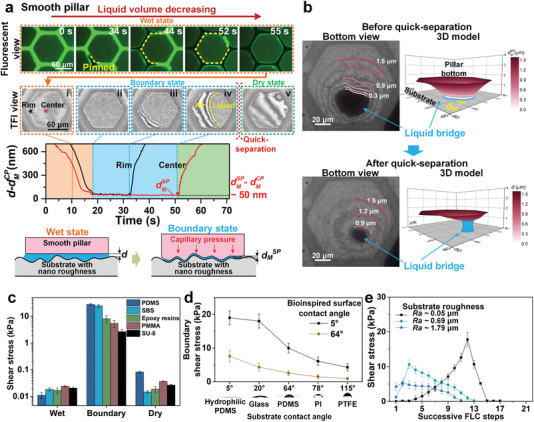

Figure 3.

Strong boundary friction formed by nanometer‐thick liquid film. a) During evaporating, fluorescence observation shows that liquid is evaporated away from channels and self‐splitting forms on pillars. With thin film interference (TFI; Figure S8a, Supporting Information) view, solid contact in nanometer thick has been observed between pillar and smooth glass substrate (roughness, ≈50 nm) at boundary state. d M SP and d M CP are the minimum gap distance of smooth pillar and concave pillar, respectively. b) The deformation of pillar bottom can be clearly depicted by the TFI fringes. Since liquid volume remains almost unchanged during quick‐separation (Figure S8b, Supporting Information), its thickness before quick‐separation d M SP is calculated by dividing the liquid volume, obtained from liquid sectional area and thickness after quick‐separation, by sectional area before quick‐separation. It is calculated to be ≈ 200 nm by recording quick‐separation of ten pillars. c) After plasma hydrophilic modification, strong boundary friction could be generated on various materials fabricated bioinspired pillar surfaces. d) Hydrophilicity for tested surfaces and substrates are crucial for generating stronger boundary friction. e) Rougher substrates lead to lower boundary friction. Data are presented as mean ± SD and sample size n = 10.