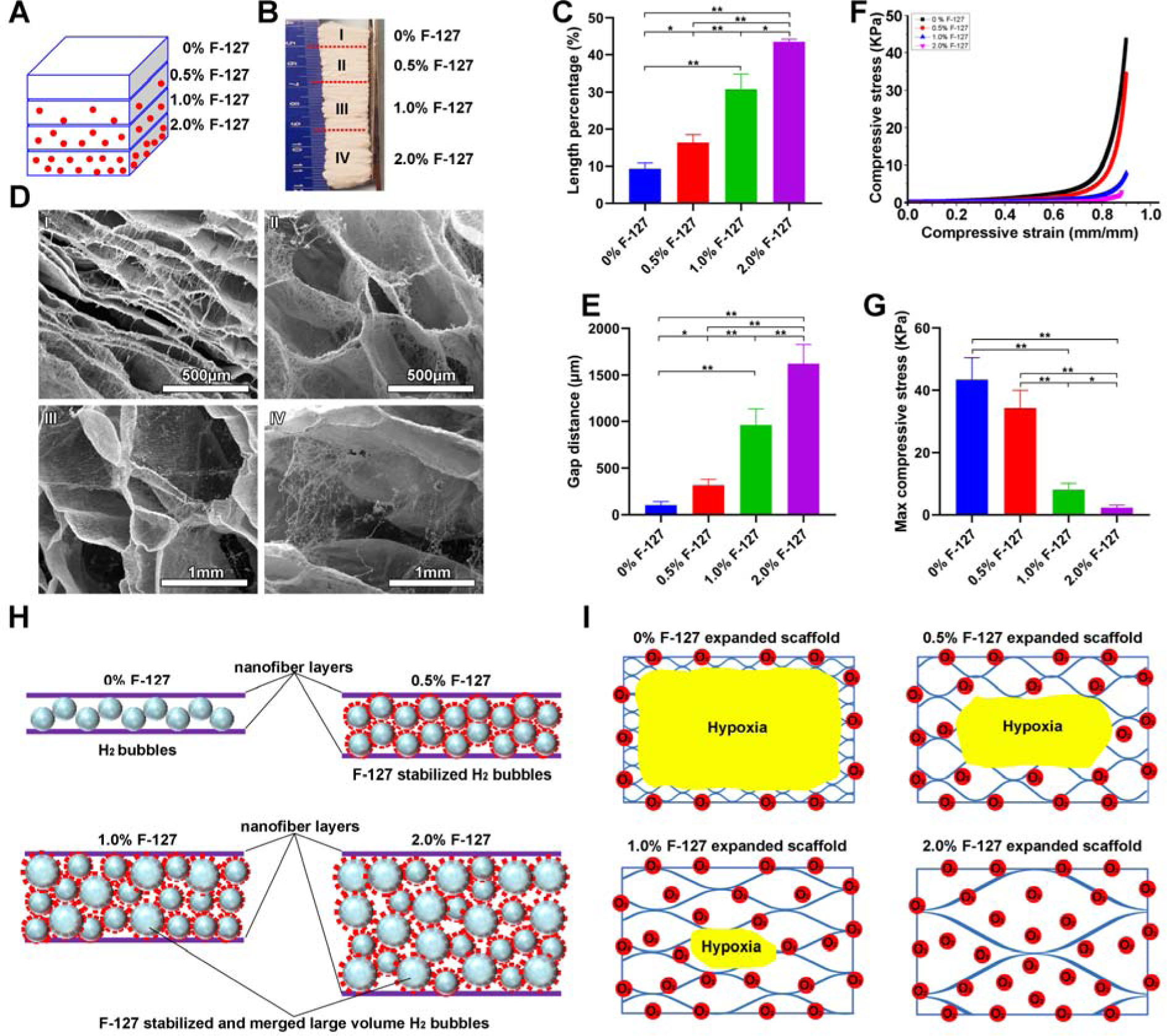

Figure 1. Preparation and characterization of a nanofiber scaffold with a discrete gradient in gap distance.

(A) Schematic illustrating a 1-mm thick PCL nanofiber mat consists of 4 regions containing 2%, 1%, 0.5% and 0% F-127 from bottom to top (each region: 250 μm). (B) Photograph of an expanded PCL nanofiber scaffold consisting of 4 regions containing 2%, 1%, 0.5% and 0% F-127 from bottom to top. (C) The length percentage of each region of expanded 3D PCL nanofiber scaffolds. (D) The morphology of cross-sections (Y-Z plane) of each region of expanded PCL nanofiber scaffolds. (E) The gap distance between two adjacent layers in each region of expanded PCL nanofiber scaffolds. (F) The compressive stress-strain curves of each region of expanded PCL nanofiber scaffolds. (G) The maximum compressive stress of each region of expanded PCL nanofiber scaffolds. (H) Schematic illustrating the expansion process of PCL nanofiber mats with blending different amounts of F-127. The F-127 additive not only enhances the hydrophilicity and water penetration of PCL nanofiber mats, and but also stabilizes the formed H2 bubbles. The small H2 bubbles can merge and grow larger in volume with increasing the concentration of F-127, resulting in a higher expansion rate. (I) Schematic showing the oxygen level of each region in expanded PCL nanofiber scaffolds in cell culture medium. * p<0.05, **p<0.01.