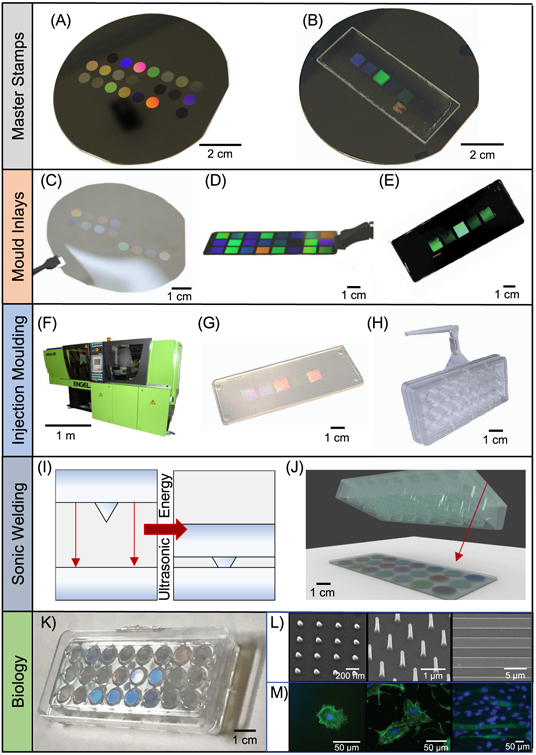

Figure 1.

Bespoke multiwell array fabrication for rapid screening of rigidity or topographical cues. We illustrate the various stages involved in the fabrication of our highly customizable multiwell array. See Experimental section for the detailed processes. First, master stamps are fabricated with the desired patterns on (A) a silicon wafer or (B) a quartz slide. The initial pattern is formed using electron beam lithography (EBL) and metal lift-off, and then etched into features using a plasma etching process. Pillars, pits or grooves can be defined on master stamps to fabricate multiwell arrays that provide topographical cues. High aspect ratio pillars can be defined on master stamps to provide controlled changes in substrate rigidity. Afterwards, a negative relief of the master stamp is fabricated by (C) nanoimprint lithography (NIL) to make a SmartNIL (EVG) foil, (D) electroplating of nickel or (E) NIL of SU-8 epoxy photoresist on Cirlex® polyimide [38]. The resulting nickel or polymer replica are used in an (F) industrial grade injection moulding Engel Victory tool, which (G) moulds thermoplastic polymers such as polystyrene or polycarbonate to replicate structures of the original master stamp onto a slide. In this paper, we focus on the use of polymeric replicates as moulds for injection moulding to prevent any adverse cell effects from nickel. (H) A bottomless well plate with 8 columns × 3 row and approximately 0.3 cm2 growth area (similar to standard 96 well plate) was also made from injection moulding of polystyrene. (I), (J) To unite the slide and the bottomless well plate, the two are brought into contact and ultrasonic energy is used to melt a weld seam on the plate into the replica to form a joint around the patterned area. (K) The multiwell array combines multiple types of biophysical cues in one plate, (L) e.g. nano-pillars, tall pillars or nano- and micro-grooves, and (M) multiple cell types. This allows for high-throughput screening of isolated cues without risk of paracrine signalling between samples confounding the effects of topography or rigidity. The standard well plate format of the multiwell array allows established analytical techniques such as microscopy to be performed easily.