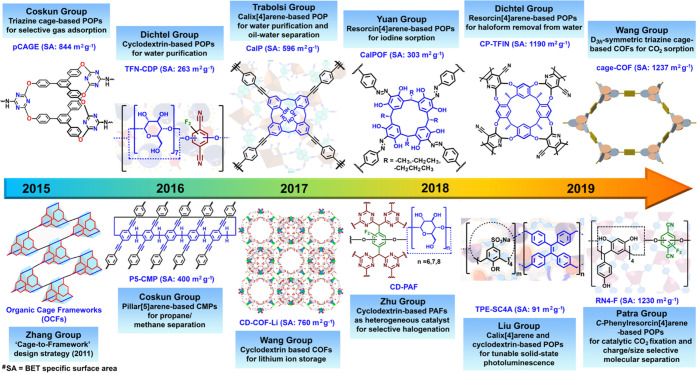

Figure 1.

Schematic illustration depicting the progressive development of organic cage and cavitand-based porous organic polymers for multifarious applications. From left to right: first demonstration of “cage-to-framework” design strategy,5 triazine cage for selective CO2 adsorption and separation,7a β-cyclodextrin-based porous polymer for micropollutant removal from water,7b pillar[5]arene-based conjugated microporous polymers for propane/methane separation,7c γ-cyclodextrin-based covalent organic frameworks for Li-ion storage,7d calix[4]arene-based porous polymer for water purification and oil–water separation,7e resorcin[4]arene-based POPs for iodine sequestration,7f α,β,γ-cyclodextrin-based postmodified porous aromatic framework for heterogeneous catalysis,7g sulfonated calix[4]arene-based POPs for solid-state tuning of photoluminescence,7h deep-cavity resorcin[4]arene-based POPs for haloform removal from water,7iD3h-symmetric triazine cage for selective CO2 sorption,7jC-phenylresorcin[4]arene-POPs for size/charge-selective molecular separation and, catalytic CO2 fixation.7k CD-COF-Li and cage-COF figures adapted with permission from ref (7d) (copyright 2017 John Wiley and Sons) and ref (7j) (copyright 2019 American Chemical Society).