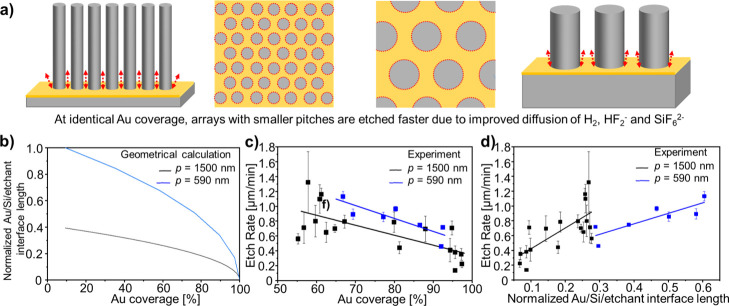

Figure 5.

Influence of Au coverage, nanowire pitch, and Au/Si/etchant interface length on the etch rate. (a) Scheme illustrating the influence of the Au/Si/etchant interface (dotted red line) and pitch on the etch rate. Both arrays represented have the same Au coverage (i.e., ∼60%) but different diameters and pitches. Left: Corresponds to p = 590 nm and d = 390 nm; Right: Corresponds to p = 1500 nm and d = 1000 nm. Smaller pitches lead to a larger Au/Si/etchant interface available for the diffusion of products and educts, which increases the etch rate. (b) Calculated normalized Au/Si/etchant interface length as a function of the Au coverage for p = 590 nm (blue line) and p = 1500 nm (black line). (c,d) Etch rate as a function of gold coverage (c) and Au/Si/etchant interface length per surface area (d). Blue squares and line: 590 nm pitch; Black squares and line: 1500 nm pitch. Both straight lines correspond to a linear fit. All substrates had an adhesion layer of AZO (75 W 1 s) and gold (40 mA 200 s) and were etched in 10:2:10 HF/H2O2/H2O. (c) 590 nm arrays show a higher etch rates for identical gold coverage. (d) For both pitches, an increase in the etch rate is observed when the Au/Si/etchant interface length increases. At an identical interface length, the etch rate is higher for the 1500 nm pitch because of its much lower gold coverage compared to arrays with a 590 nm pitch.