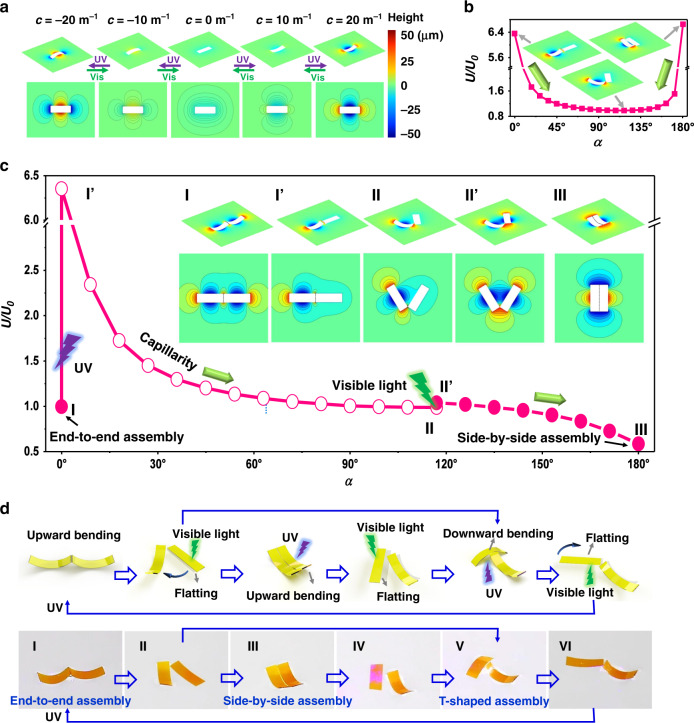

Fig. 3. Mechanism of optocapillarity-driven reconfiguration.

(a) Three-dimensional air-water interface morphology as well as corresponding iso-height contour diagrams vary when the actuator bends and unbends by alternative irradiation of UV and visible light. The colorbar represents the height from the horizontal plane, same as in (b, c) (b) The total Gibbs free energy of the system composed of an up-bending actuator (с1 = 20 m−1) and a flat actuator (с2 = 0) varies with the orientation angle α. Light irradiation makes one actuator flat and the other remains curved, when they contact end to end or side by side, the system is extremely unstable and then they rotate spontaneously via capillary to reach equilibrium to avoid assembling in alignment. The arrow represents the direction in which the potential energy of the system decreases. The inset illustrations show the water-air surface morphology obtained by numerical calculation. (c) Plot showing the total Gibbs free energy in the two-actuator system during the transformation from Case 1. The curve shows the path to realize the desired transformation and the inset illustrations show the 2D and 3D air-water surface morphology obtained by numerical calculation. (d) Schematics (above) and experimental photographs (below) showing optocapillarity-driven reconfiguration of two actuators (Part 2-1 of Supplementary Movie 1). To achieve the reconfiguration from end-to-end assembly (I) to side-by-side assembly (III), firstly we can illuminate one actuator with visible light to make it flat, and the flattened actuator rotated (II). When the orientation angle of the two actuators was close to 120°, the flattened actuator was illuminated with UV light to bend it upwards, and then the two actuators formed side-by-side assembly (III). To gain the reconfiguration from side-by-side assembly (III) to T-shaped assembly (V), one actuator was irradiated with visible light (IV). The flattened actuator was irradiated with UV light at the bottom surface to bend it downwards. Then the two actuators aggregated into a T-shaped assembly (V). Using the same methods, the T-shaped assembly can be reconfigured again into the end-to-end assembly.