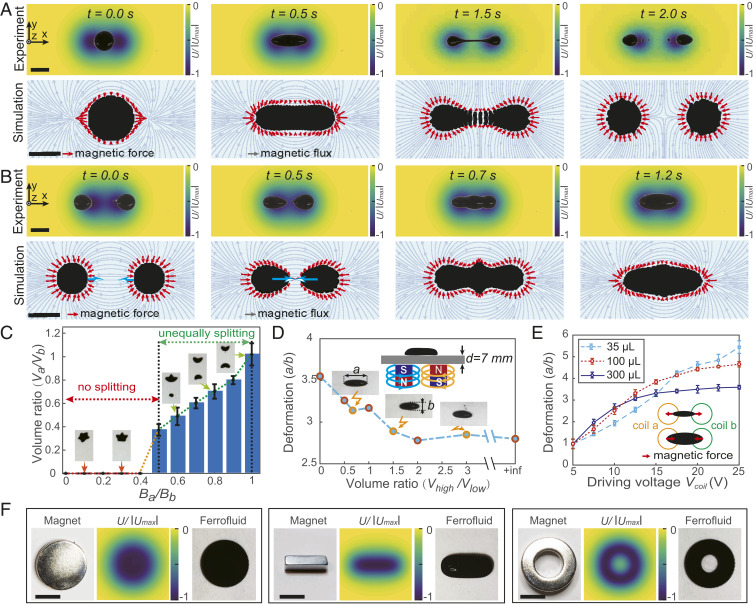

Fig. 2.

Control mechanism and characterization of extreme and complex deformations of FDRs. (A) Experimental and simulated time frames of the controllable splitting behavior of an FDR. (B) Experimental and simulated time frames of the controllable merging behavior of an FDR. In A and B, the top row has the experimental video snapshots overlapped on the simulated magnetic potential-energy distributions. (C) The volume ratio of two split droplets as a function of the relative magnetic field strength produced by two coils under the droplets. (D) The deformation of an FDR as a function of the mixing-volume ratio of two types of ferrofluids (dynamic viscosities: ). The deformation here is defined as the relative length ratio between the long axis and short axis of the FDR. (E) The deformation of an FDR as a function of different driving voltages (or equivalently magnetic-field strengths). (F) Programming complex shapes of an FDR using distributed produced by ferromagnets in disk-, cube-, and ring-shapes. The color maps represent the normalized on the actuation plane at 5 mm above the ferromagnets. In all experiments except that in D, only the ferrofluids with dynamic viscosities of 8 mPa·s (EMG 901; Ferrotec Corporation) were used here. (Scale bars, 10 mm.)