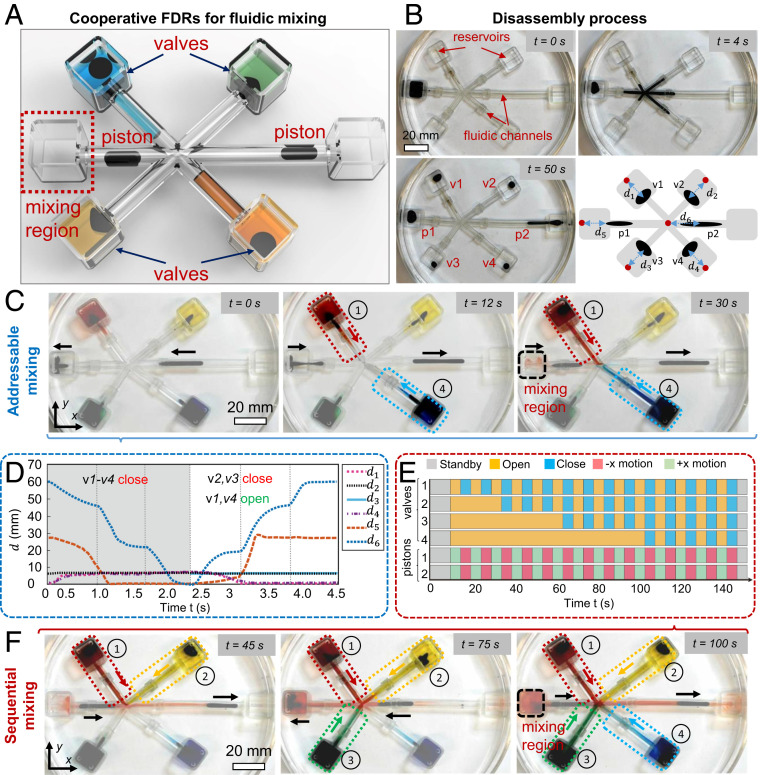

Fig. 7.

Multiple FDRs demonstrating programmable fluidic mixing by coordinated independent motion control. (A) Concept of the programmable fluidic-mixing device. The motion of each FDR can be controlled independently to work either as a piston or valve. The selected liquids in an arbitrary reservoir can be pumped into the “mixing zone” by controlling the “open” or “closed” states of the corresponding valve. (B) A single FDR is injected into a fluidic channel with a specific topology and then disassemble into multiple FDRs. States of the device are characterized by the relative displacement from the ith FDR to its reference point. The valve is open or closed when the FDR is far away from or close to the reference point, respectively. The dye is pumped into or away from the main channel when the FDR as a piston is far away from or close to the reference point, respectively. (C) Sequential video snapshots of selectively mixing the red and blue dyes. The selected channels are marked with dashed rectangles. (D) The sequential relative displacements of all FDRs in C within a full pumping period. (E) Sequential states of the valves and pistons in the demonstration of sequentially mixing dyes in four channels according to a specified order (“1-2-3-4”). (F) Video snapshots of sequentially mixing dyes in four channels corresponding to the sequential system states shown in E. In all experiments, ferrofluids with a dynamic viscosity of 8 mPa·s were used. The average volume flow rate of the flow into the mixing region is about 23.6 µL·s−1 in C and F.