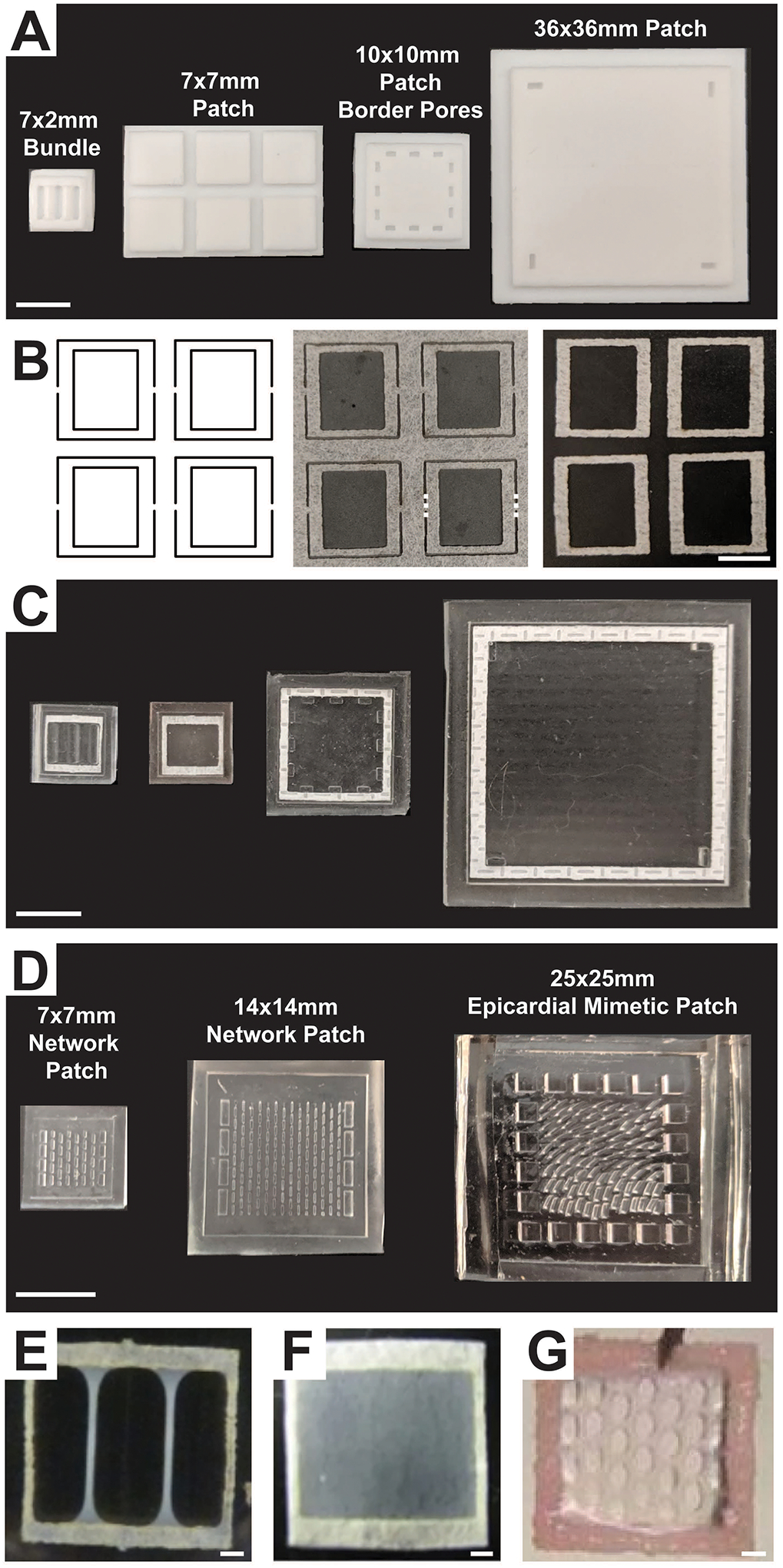

Figure 1 –

(A) PTFE master negatives used to manufacture PDMS molds for generating a 7 × 2 mm bundle, a 7 × 7 mm patch, a 10 × 10 mm patch with border pores, and a 36 × 36 mm patch. Scale bar = 10 mm. (B) Left: laser cutter path to generate frames within a nylon sheet; Middle: laser-cut frames attached to sheet with thin bridges (dashed lines). Right: nylon frames cut from the main sheet at the bridges. Scale bar = 5 mm. (C) Resulting PDMS molds generated from the masters shown in (A) with nylon frames pressed in. Scale bar = 10 mm. (D) PDMS molds for fabrication of a 7 × 7 mm and a 14 × 14 mm network patch and a 25 × 25 mm epicardial mimetic patch. These molds were generated using high aspect ratio soft lithography. Scale bar = 10 mm. Appearance of 7 × 7mm (E) bundle, (F) patch, and (G) network engineered cardiac tissues after 2–3 weeks of culture. Scale bar = 1 mm. (Figure contains elements reproduced from references [2,16,18] with permission)