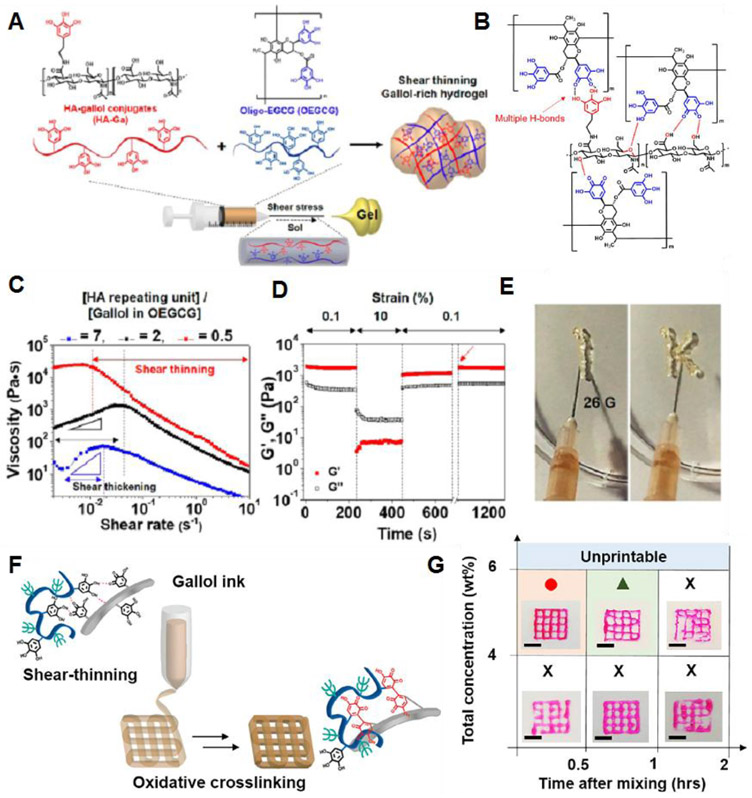

Figure 5.

(A) Schematic illustration for preparing gallol-rich, shear-thinning hydrogels of HA-Ga/OEGCG. (B) The proposed multiple hydrogen bond formation (red dashed line) between the gallol-to-gallol moieties and gallol-to-HA backbone. (C) Changes in viscosity as a function of shear rates for HA-Ga/OEGCG hydrogels with the [HA unit]/[gallol in OEGCG] ratio of 7 (blue), 2 (black), or 0.5 (red). (D) The recovery measurement of G′ displaying the hydrogel structure under alternating strain from 0.1% to 10% back down to 0.1%. (E) A photograph showing the injectability of the HA-Ga/OEGCG hydrogel (the ratio = 0.5) using a 26G needle (inner diameter = 0.26 mm). Reprinted with permission from ref136. Copyright 2017 American Chemical Society. (F) Schematic illustration of the 3D printing where the gallol ECM hydrogel ink transitions from a shear-thinning hydrogel during printing to one with mechanical stabilization via oxidation after the printing. (G) Printability of the gallol ECM ink with various concentrations (4, 6 wt%) and injectability as a function of the time after gel formation (0.5, 1, 2 h). Scale bars of 4 mm. Reprinted with permission from ref138. Copyright 2019 Elsevier.