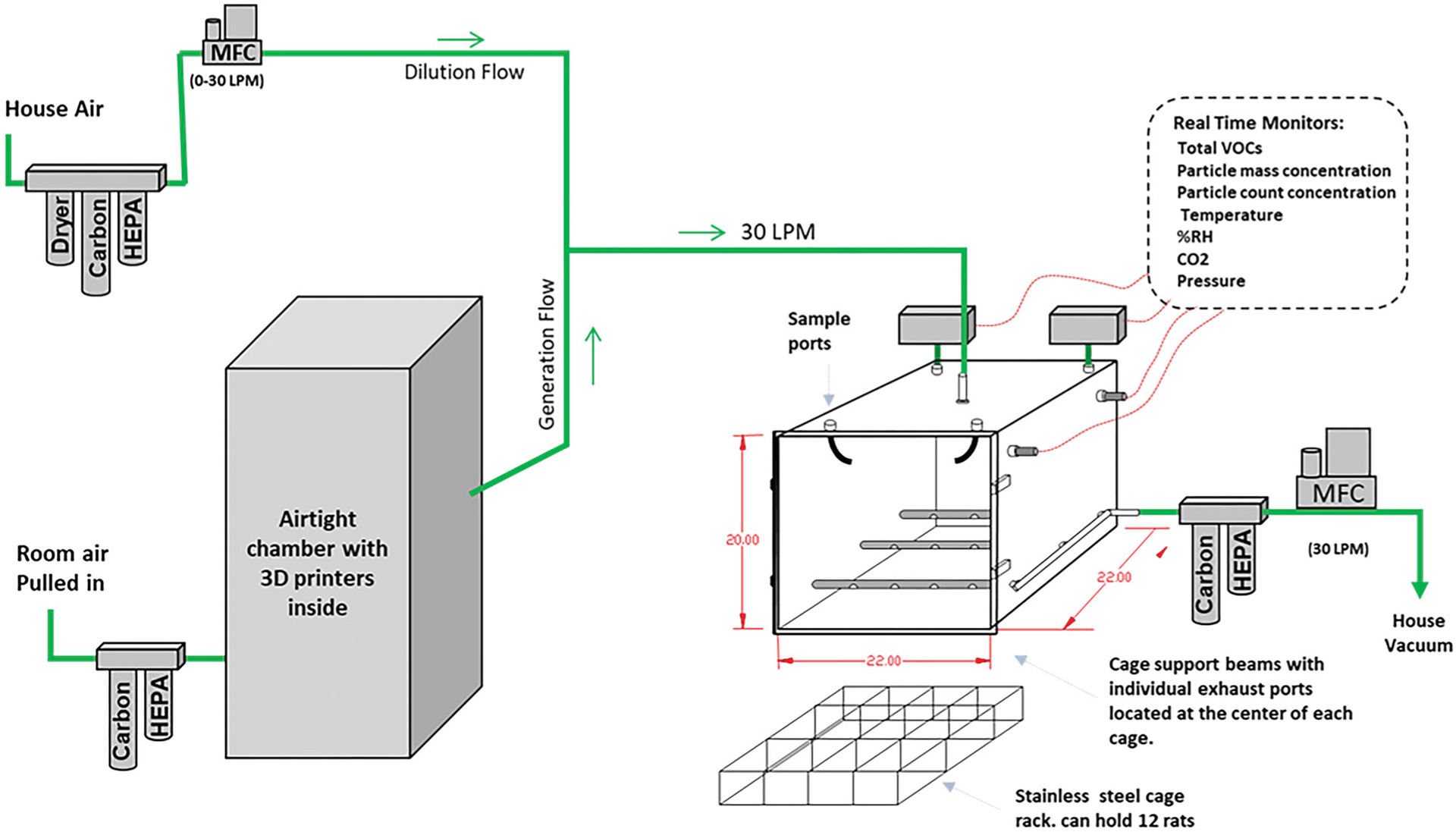

Figure 1.

Diagram of the custom-built computer automated inhalation exposure system for testing the ABS 3-D printing emissions. The exposure chamber air was exhausted into a carbon/high-efficiency particulate air (HEPA) filter bank. The flow rate of this air was controlled by a mass flow controller that had its downstream port connected to a hose vacuum. During exposures, this flow was held constant at 30 l/min (LPM). The airflow was controlled using multiple mass flow controllers (MFC) operated at continuous flow rates. Animals were exposed to fumes (particles and gasses) generated from three commercially available 3-D printers placed inside an airtight chamber (300 l volume).