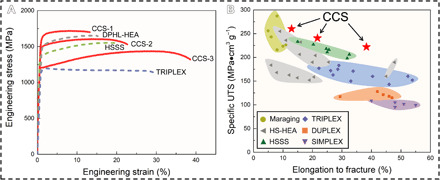

Fig. 3. Mechanical properties of CCSs.

(A) Engineering stress-strain curves of CCSs. CCS-1, CCS-2, and CCS-3 correspond to CCSs annealed at 800°, 850°, and 900°C, respectively. Tensile properties of the CCSs together with those of representative conventional lightweight steels (TRIPLEX) (36), HSSS (6), and high-strength dual-phase heterogeneous lamella structured HEAs (DPHL-HEAs) (21) are shown for comparison. As representative examples of advanced lightweight steels and high-strength HEAs, the HSSS and DPHL chosen here have similar grain sizes compared to our CCSs. (B) Plot of specific UTS (UTS per mass density) as a function of elongation for CCSs and the reference alloys named above. The overall mechanical performance of our CCSs surpasses that of any other high-strength HEAs (HS-HEA) (21, 24–33), conventional lightweight steels [including SIMPLEX (35), DUPLEX (34, 36), and TRIPLEX (4, 36)], advanced lightweight steels (HSSS) (6, 7), and high-strength maraging steels (22, 23).