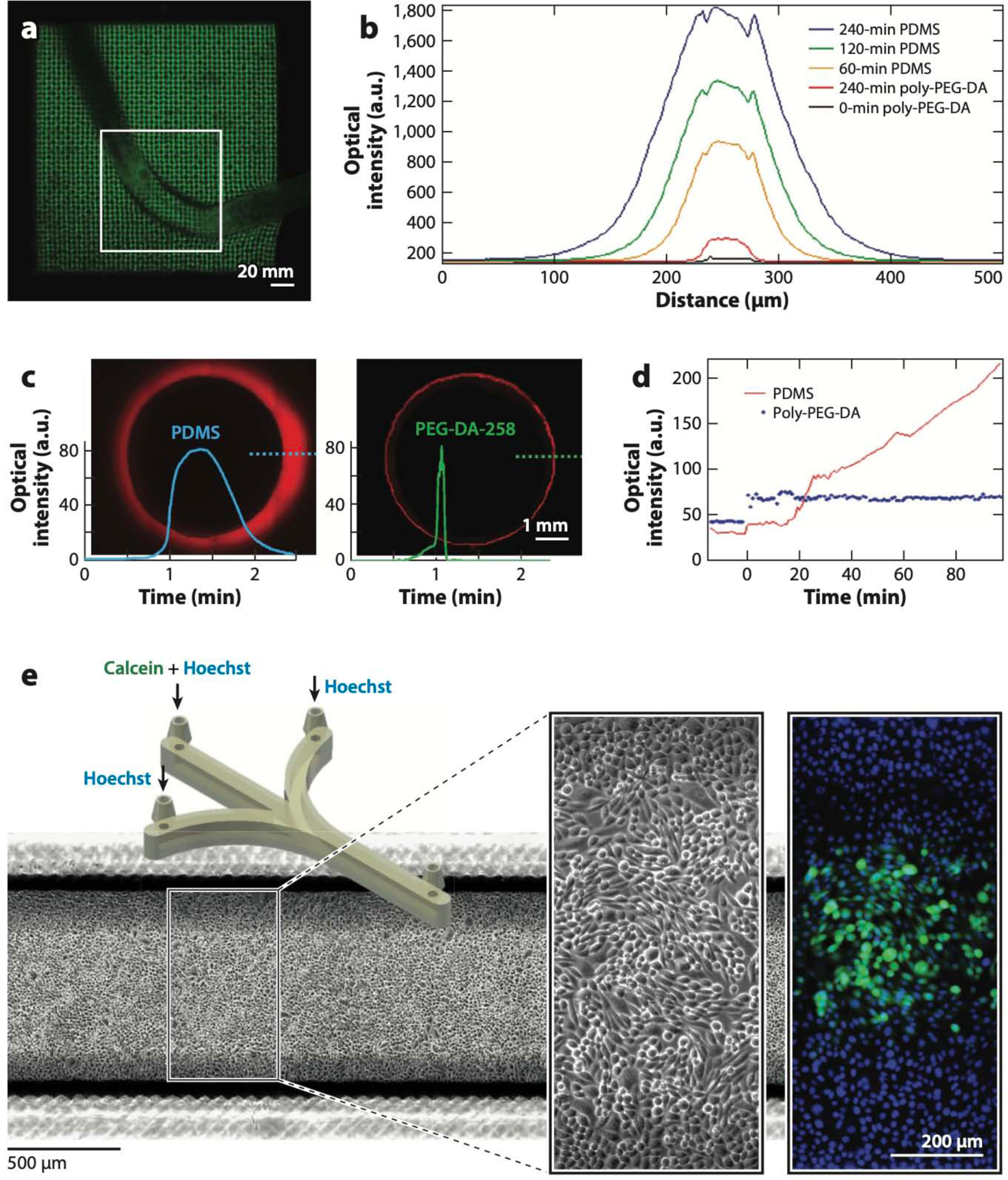

Figure 6:

Biocompatibility of digitally manufactured microfluidics. (a) Live Caenorhabditis elegans trapped in stereolithography (SL)-printed poly(ethylene glycol) diacrylate (PEG-DA)-700 hydrogel woodpile microstructures. (b) Comparison of the cross-sectional fluorescence profiles of molded PEG-DA-258 and poly(dimethyl siloxane) (PDMS) 50-μm-wide microchannels filled with 10 μM Rhodamine B for various amounts of time as indicated. (c) Comparison of the cross-sectional fluorescence profiles of thermally cured PDMS (left) and 3D-printed PEG-DA-258 (right) 5-mm-wide wells after being exposed to 1 mM Nile Red for 90 min. (d) Comparison of the fluorescence levels of molded PDMS and PEG-DA-258 as a function of time during exposure to a fluorescently labeled protein (1 μg/mL FITC-BSA). (e) CAD design of the SL-printed microfluidic device (left inset) in which CHO-K1 cells were cultured and labeled with Hoechst 33342 and Calcein Green AM (right inset). Abbreviations: a.u., arbitrary units; CAD, computer-aided design. Panel a adapted from Reference 229 under a Creative Commons license (CC-BY-4.0). Panels b and d adapted from Reference 256 with permission from the American Chemical Society. Panels c and e adapted from Reference 258 courtesy of A. Kuo and A. Folch.