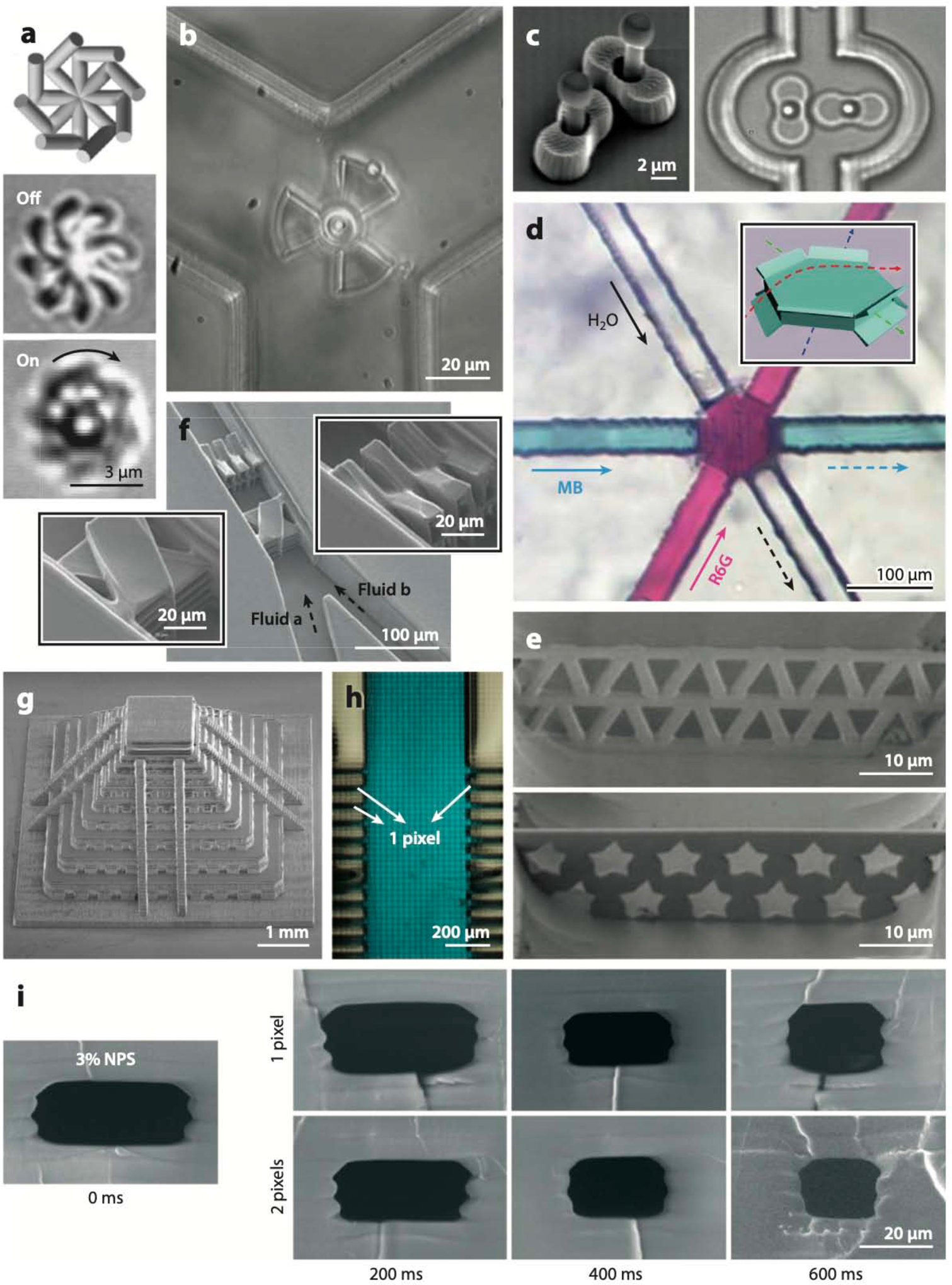

Figure 7:

Microfluidic devices printed at high resolution. (a) Polymer structures stereolithography (SL)-printed in the optical adhesive Norland NOA 63 (top) can be rotated off (middle) and on (bottom) by laser illumination. (b) Magnetically actuated microturbine SL-printed in a ferrofluid resin. (c) Micropump that is SL-printed and actuated with laser tweezers. (d) Fluid junction overpass fabricated by direct laser writing (DLW). (e) Microsieves with triangular (top) and pentagrammic (bottom) pores fabricated by DLW. (f) 3D micromixer featuring crisscrossing manifolds fabricated by DLW. (g) Micropyramid test structure SL-printed with the Dilase 3D, a high-resolution laser-based 3D printer. (h) A 500-μm-wide poly(ethylene glycol) diacrylate (PEG-DA)-258 channel connected to a series of 1-mm-tall, 27-μm-wide (one pixel wide; aspect ratio, 37:1) parallel microchannels. (i) Microfluidic PEG-DA-258 microchannels with cross sections as small as 18 μm × 20 μm. Abbreviations: NPS, 2-nitrophenyl phenyl sulfide; MB, blue methylene blue trihydrate; R6G, Rhodamine 6G. Panel a adapted from Reference 274 with permission from AIP Publishing. Panel b adapted from Reference 267 with permission from the Royal Society of Chemistry (RSC). Panel c adapted from Reference 277 with permission from AIP Publishing. Panel d adapted from Reference 279 with permission from the RSC. Panel e adapted from Reference 280 with permission from the RSC. Panel f adapted from Reference 284 with permission from the RSC. Panel g adapted courtesy of Kloe, Inc. Panel h adapted from Reference 258 courtesy of A. Kuo and A. Folch. Panel i adapted from Reference 273 with permission from the RSC.