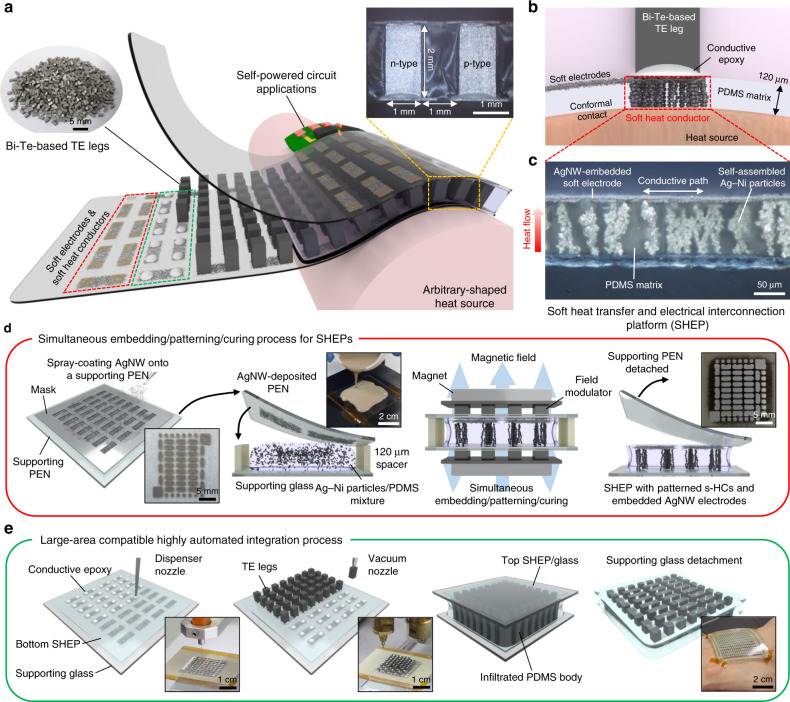

Fig. 1. Design and fabrication process for compliant thermoelectric generator (TEGs).

a Conceptual illustration of a compliant TEG with soft electrodes and soft heat conductors (s-HCs) for self-powered circuit applications. The left inset is a photograph of bismuth telluride (Bi2Te3)-based thermoelectric (TE) legs and the right inset is an optical image of a cross-section of the compliant TEG. Scale bars, 5 and 1 mm. b Schematic illustration showing the structure of the compliant TEG establishing conformal contact with an arbitrary-shaped heat source. The s-HCs efficiently transfer heat energy from the heat source to the TE legs, and the soft electrodes allow a high degree of mechanical freedom. c Microscopic image of the soft heat transfer and electrical interconnection platform (SHEP) with embedded soft silver nanowire (AgNW) electrodes and patterned silver-coated nickel (Ag–Ni) s-HCs. Scale bar, 50 μm. d Schematic illustration and photographs of simultaneous embedding/patterning/curing process for the SHEPs. Scale bars, 5 mm, 2 cm, and 5 mm. e Schematic illustration and photographs of a large-area compatible fully automated integration process using a programmable dispenser and a pick-and-place machine. The rightmost photograph shows a compliant TEG comprising 440 TE legs conformably attached to human skin. Scale bars, 1 cm.