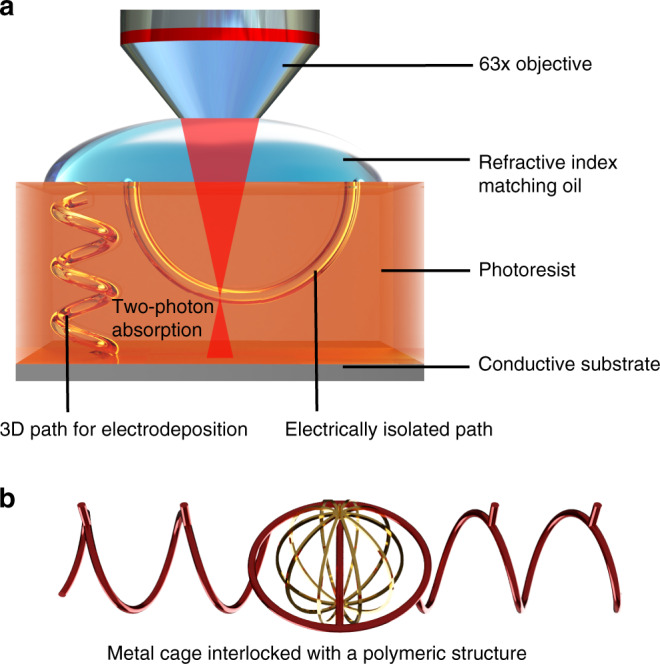

Fig. 1. Fabrication of interlocked structures.

a A polymeric bar is placed through the empty spaces of a metallic structure to interlock dissimilar materials. These two materials remain mechanically bound to each other through a closed ring. There is no design constraint over the shapes connected to the ring, as long as outlets are properly placed for material infusion through the microchannels. b To fabricate these structures, a high aperture objective is used in a two-photon absorption setup using a positive-tone photoresist immersed in a refractive index matching oil. This configuration allows for accurate detection of the photoresist/substrate interface. As a result, it is possible to design vias independently, which may be suitable for electrodeposition or not. The microchannels that are electrically isolated will remain unfilled after the electrodeposition step is concluded. As a result, a second casting step can be performed to mold water-soluble polymers. Consequently, two completely independent geometries composed of different materials can be obtained after dissolving the mold.