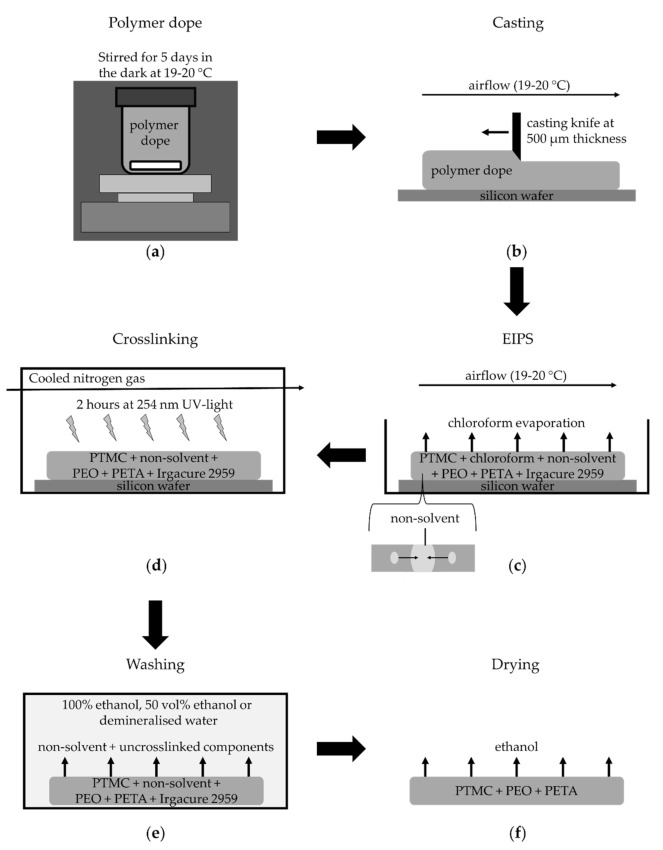

Scheme 1.

Schematic of PTMC membrane fabrication by EIPS. (a) The polymer dope is stirred for five days at 19–20 °C in the dark. (b) The dope is then cast on silicon wafers in a 500 µm thick layer using a casting knife. (c) The cast polymer layers are kept in a box for 90 min where chloroform evaporation and EIPS occurs. (d) The membranes are then crosslinked in a UV-box for two hours at 254 nm UV-light with cooled nitrogen gas flowing through the UV-box. (e) Membranes are then washed to remove the non-solvent and any other uncrosslinked components. (f) Finally, the membranes are rinsed with ethanol, dried and stored.