Abstract

Cattle of different ages may have to be killed on farm for purposes other than slaughter (the latter being defined as killing for human consumption) either individually or on a large scale, e.g. for economic reasons or for disease control. The purpose of this scientific opinion is to assess the risks associated with the on‐farm killing of cattle. The processes during on‐farm killing that were assessed included handling and moving, stunning and/or killing methods (including restraint). The killing methods were grouped into mechanical and electrical methods as well as lethal injection. In total, 21 hazards compromising animal welfare were identified and characterised, most of these related to stunning and/or killing. Staff was identified as an origin for all hazards, either due to lack of appropriate skills needed to perform tasks or due to fatigue. Possible preventive and corrective measures were assessed: measures to correct hazards were identified for 19 hazards, and the staff was shown to have a crucial role in prevention. Three welfare consequences of hazards to which cattle can be exposed during on‐farm killing were identified: impeded movement, pain and fear. The welfare consequences and relevant animal‐based measures related to these were described. Outcome tables linking hazards, welfare consequences, animal‐based measures, origins of the hazards, preventive and corrective measures were developed for each process. Mitigation measures to minimise the welfare consequences are proposed.

Keywords: cattle, bison, buffalo, on‐farm killing, hazards, animal welfare consequences, animal‐based measures, preventive and corrective measures

Summary

In 2009, the European Union (EU) adopted Council Regulation (EC) No. 1099/2009 ‘on the protection of animals at the time of killing’, which was prepared on the basis of two scientific opinions adopted by the European Food Safety Authority (EFSA) in 2004 and 2006. In 2013, EFSA produced another scientific opinion related to this subject.

In parallel, since 2005, the World Organisation for Animal Health (OIE) has developed two chapters in its Terrestrial Animal Health Code: (i) Slaughter of animals (Chapter 7.5), (ii) Killing of animals for disease control purposes (Chapter 7.6). OIE has created an ad hoc working group to revise these two chapters.

Against this background, the European Commission requested EFSA to develop a scientific opinion providing an independent view on the killing of cattle for purposes other than slaughter (the latter being defined as killing animals for human consumption), which includes: (i) large‐scale killings for disease control and for other situations, like environmental disaster management; and (ii) on‐farm individual killing of animals that are injured or terminally ill to end pain and suffering due to the lack of treatment options.

With specific reference to handling and moving, restraint and killing, EFSA was asked to: identify the animal welfare hazards present during on‐farm killing and their possible origins in terms of facilities/equipment and staff [Term of Reference (ToR) 1]; define qualitative or measurable criteria to assess performance on animal welfare [animal‐based measures (ABMs) (ToR2); provide preventive and corrective measures (structural or managerial) to address the hazards identified (ToR3); and point out specific hazards related to species or types of animals (e.g. buffaloes; ToR4). The European Commission also asked EFSA to provide measures to mitigate the welfare consequences that can be caused by the identified hazards. This scientific opinion aims to update the above‐reported EFSA outputs by reviewing the most recent scientific publications and providing the European Commission with a sound scientific basis for future discussions at international level on the welfare of animals in the context of killing for purposes other than slaughter.

The mandate also requested a list of unacceptable methods, procedures or practices that need to be analysed in terms of the above welfare aspects. It has to be noted that methods, procedures or practices cannot be subjected to a risk assessment procedure if there is no published scientific evidence related to them. Chapter 7.5.10 of the OIE Terrestrial Animal Health Code includes a list of several unacceptable practices and the Panel agrees with this list. In addition, the Panel listed some practices that lead to serious welfare concerns during the on‐farm killing of cattle. These practices should be avoided, redesigned or replaced by other practices, leading to better welfare outcomes. Finally, the Panel provided a list of methods that are highly painful and should never be used on welfare grounds. To address the mandate, two main approaches have been used to develop this scientific opinion: i) literature search; followed by ii) expert opinion through Working Group (WG) discussion. The literature search was carried out to identify peer‐reviewed scientific evidence providing information on the aspects requested by the ToRs (i.e. description of the processes, and identification of welfare hazards, their origin, preventive and corrective measures, welfare consequences and related animal‐based measures). From the available literature and their own knowledge, the WG experts identified the processes that should be included in the assessment and produced a list of the possible welfare hazards present during each process related to on‐farm killing of cattle. To address the ToRs, the experts identified the origin of each hazard (ToR‐1) and related preventive and corrective measures (ToR‐3), along with the possible welfare consequences of the hazards and relevant animal‐based measures (ToR‐2). Measures to mitigate the welfare consequences were also considered. Specific hazards were identified in relation to particular types of animals (ToR‐4), for example, the thick skull of buffaloes and bisons requiring adapted mechanical methods. In addition, an uncertainty analysis on the hazard identification process was carried out, limited to quantifying the probability of wrongly omitting true hazards (i.e. false negatives) or wrongly including non‐hazards (false positives) in the assessment. The processes assessed in this scientific opinion are handling/moving and killing. The description of the restraint, when needed, has been included in the assessment of the relevant killing methods. As this scientific opinion will be used by the European Commission to address the OIE standards, more killing methods than those reported in Council Regulation (EC) No 1099/2009 have been considered. However, among the methods that are used worldwide, the following criteria for the selection of those included in this assessment have been applied: a) all methods with described technical specifications known to the experts, not only those described in Council Regulation (EC) No. 1099/2009, and b) methods currently used for killing of cattle as well as those still in development but likely to become commercially applicable and c) methods for which the welfare aspects (in terms of welfare hazards, welfare consequences, ABMs, preventive and corrective measures) are described sufficiently in the scientific literature. Applying these criteria, some methods that may be applied worldwide have not been included in the current assessment.

The killing methods that have been identified as relevant for cattle can be grouped into three categories: (1) mechanical, (2) electrical and (3) lethal injection.

Mechanical methods include penetrative captive bolt followed by a killing method (pithing, sticking or lethal injection), non‐penetrative captive bolt followed by a killing method and firearm with free projectile. In the electrical killing methods, head‐only electrical stunning is followed (or applied at the same time) by application of the electrical current across the chest to span the heart. Lethal injection involves injection of overdose of anaesthetic drugs that cause rapid loss of consciousness followed by death.

In response to ToR‐2, three welfare consequences that cattle may experience during on‐farm killing have been identified: impeded movement, pain and fear. ABMs for the assessment of these welfare consequences have subsequently been identified.

In the killing phase, cattle may experience welfare consequences if hazards occur during restraint (before killing method application), or if killing is ineffective. Since consciousness is a prerequisite to experience pain and fear during killing, the ABMs of the state of consciousness are assessed during the killing process to identify the possibility that cattle experience pain and fear. These ABMs of the state of consciousness are specific to the killing methods and some of them were proposed in a previous EFSA opinion (EFSA AHAW Panel, 2013). Flowcharts, including ABMs of the state of consciousness to be used for monitoring of killing efficacy, are reproduced in this scientific opinion in order to provide the European Commission with the full welfare assessment at killing.

In answering ToR‐1, 21 related hazards having welfare consequences were identified. All the processes described in this scientific opinion have hazards. The main hazards are associated with lack of staff skills and training, and poorly designed facilities or badly maintained equipment. Animal welfare consequences can be the result of one or more hazards. Exposure to multiple hazards has a cumulative effect on the welfare consequences (e.g. pain due to injury caused during handling and moving will lead to more severe pain during killing). Some hazards are inherent to the killing method and cannot be avoided (e.g. restraining), other hazards originate from suboptimal application of the method, mainly due to unskilled staff (e.g. inappropriate handling, use of wrong parameters e.g. for electrical methods). In fact, staff was identified as one of the origins for all the hazards, in particular related to lack of appropriate skill sets needed to perform the moving and handling, restraining and killing or to fatigue.

The uncertainty analysis on the set of hazards provided for each process in this scientific opinion revealed that the experts were 95–99% certain that all listed hazards may occur during killing of cattle. However, the experts were 95–99% certain that at least one welfare hazard was missing in their assessment. This is due to the lack of documented evidence on all possible variations in the processes and methods being practised worldwide (see Interpretation of ToRs on the criteria for selection of killing methods to be included).

In response to ToR‐3, preventive and corrective measures for the identified hazards have been identified and described. Some measures apply for a specific hazard; others can apply to multiple hazards (e.g. staff training). For all the hazards, preventive measures can be put in place with management having a crucial role in prevention. Corrective measures were identified for 19 hazards; when they are not available or feasible to put in place, actions to mitigate the welfare consequences caused by the identified hazards should be put in place.

Outcome tables summarising all the mentioned elements requested by the ToRs (identification of welfare hazards, origin, preventive and corrective measures, welfare consequences and related ABMs) have been produced for each process and killing method to provide an overall outcome, where all retrieved information is presented concisely. Conclusions and recommendations subdivided by phase and specific killing method are provided. To spare cattle from severe welfare consequences, a standard operating procedure (SOP) should include identification of hazards and related welfare consequences using relevant ABMs, as well as preventive and corrective measures at each phase of killing. Training of staff is a key preventive measure to avoid hazards and mitigate welfare consequences. All processes of the killing should be carried out by trained and skilled personnel. Ideally, cattle should be killed in their home pens and carcasses moved for disposal. If movement of cattle is required, the distance from the home pens to the point of killing should be kept to a minimum and the animals should be moved gently. Painful stimuli, such as electric goads, hitting with a stick etc. must be avoided. Instead, passive stimuli such as flags and paddles should be used. To monitor the efficacy of the killing method, the state of consciousness and death of the animals should be checked at each step – i.e. after stunning, after the application of a killing procedure and before carcass disposal – using the suggested ABMs.

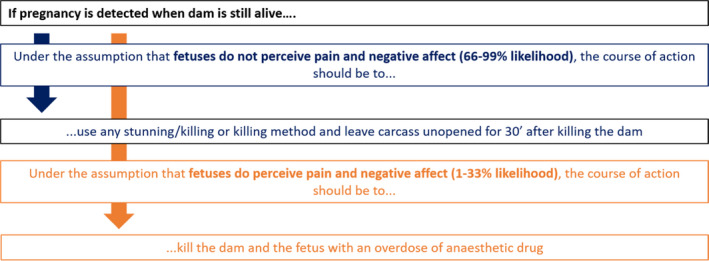

Finally, in response of ToR‐4 specific hazards and preventive measures are presented for pregnant cows, extensively raised animals, breeding bulls, buffaloes and bison.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

1.1.1. Background

The European Union adopted in 2009 Council Regulation (EC) No 1099/20091 on the protection of animals at the time of killing. This piece of legislation was prepared on the basis of two EFSA scientific opinions respectively adopted in 20042 and 2006.3 The EFSA provided additional scientific opinions related to this subject in 2012,4 20135 , 6 , 7 , 8 , 9 , 10 201411 , 12 201513 and 2017.14 , 15

In parallel, since 2005, the World Organisation for Animal Health (OIE) has developed in its Terrestrial Animal Health Code two chapters covering a similar scope:

-

–

Slaughter of animals (Chapter 7.5)

-

–

Killing of animals for disease control purposes (Chapter 7.6)

The chapter slaughter of animals covers the following species: cattle, buffalo, bison, sheep, goats, camelids, deer, horses, pigs, ratites, rabbits and poultry (domestic birds as defined by the OIE).

The OIE has created an ad hoc working group with the view to revise the two chapters.

Against this background, the Commission would like to request the EFSA to review the scientific publications provided and possibly other sources to provide a sound scientific basis for the future discussions at international level on the welfare of animals in the context of slaughter (i.e. killing animals for human consumption) or other types of killing (killing for other purposes than slaughter).

Terms of Reference

The Commission therefore considers it opportune to request EFSA to give an independent view on the killing of animals for other purposes than slaughter:

-

–

free moving animals (cattle, buffalo, bison, sheep, goats, camelids, deer, horses, pigs, ratites)

-

–

animals transported in crates or containers (i.e. rabbits and domestic birds).

The request focuses on the cases of large scale killing which take place in case of depopulation for disease control purposes and for other similar situations (environmental contamination, disaster management, etc.) outside slaughterhouses.

The request also considers in a separate section the killing of unproductive animals that might be practiced on‐farm (day‐old chicks, piglets, pullets, etc.)

The request includes the following issues:

-

–

handling,

-

–

restraint,

-

–

stunning/killing,

-

–

unacceptable methods, procedures or practices on welfare grounds.

For each process or issue in each category (i.e. free moving/in crates or containers), EFSA will:

-

–

Identify the animal welfare hazards and their possible origins (facilities/equipment, staff),

-

–

Define qualitative or measurable criteria to assess performance on animal welfare (ABMs),

-

–

Provide preventive and corrective measures to address the hazards identified (through structural or managerial measures),

-

–

Point out specific hazards related to species or types of animals (young, with horns, etc.).

1.2. Interpretation of the Terms of Reference

This scientific opinion concerns the killing of cattle including buffaloes and bison for purposes other than slaughter. A separate scientific opinion, which deals with welfare of cattle at slaughter (EFSA AHAW Panel, 2020), is referred to in the present document.

The European Commission asked EFSA to provide an independent view on the welfare of cattle during on‐farm killing for purposes other than slaughter, which takes place during the following scenarios: a) large‐scale killings (depopulation for disease control purposes and for other similar situations, such as environmental contamination, disaster management etc.) outside the slaughterhouses, and b) individual on‐farm killing of unproductive animals. The Panel agreed to include in this latter category the animals that are injured or terminally ill. For each of these scenarios, several welfare aspects need to be analysed (including e.g. welfare hazards, hazard origins, animal‐based measures and corrective measures).

This scientific opinion will use definitions related to the killing of cattle provided by the Council Regulation (EC) No 1099/2009 of 24 September 2009 on the protection of animals at the time of killing, which entered into force in January 2013. In this scientific opinion killing refers to any intentionally applied procedure that causes death of the animal. The processes involved in this operation are (1) handling and moving and (2) killing methods.

Considering that the restraint of cattle prior to killing (including stunning if a stunning method is applied before killing the cattle) varies depending on the killing method, the restraint will be included in the assessment of the relevant killing method. The main methods relevant for cattle identified can be grouped in three categories: (1) mechanical, (2) electrical and (3) lethal injection.

The mandate requests EFSA to identify hazards at the different phases (‘Handling/moving’, ‘Killing’) of killing for other purposes than slaughter and their relevant origins in terms of equipment/facilities or staff (ToR‐1). Due to the diversity of available killing methods, in this scientific opinion, the assessment of hazards, welfare consequences and related ABMs, hazards’ origin and preventive/corrective actions will be dealt with separately for each method. Mitigation measures to minimise animal welfare consequences are also described.

The mandate also asks to define qualitative or measurable (quantitative) criteria to assess performance on animal welfare (ABMs; ToR‐2). This ToR has been addressed by identifying and describing the negative consequences on the welfare (so‐called ‘welfare consequences’) occurring to the cattle due to the identified hazards and the relevant ABMs that can be used to assess qualitatively and/or quantitatively the welfare consequences.

A ranking of the identified hazards in terms of severity, magnitude and frequency of the welfare consequences that they can cause would have been useful to prioritise actions and improve the procedure of the on‐farm killing; however, this has not been performed due to the limited time for this mandate.

This scientific opinion will also propose preventive and corrective measures for the identified hazards; these measures will refer to two main categories: 1) equipment and 2) managerial (ToR3). When corrective measures for the hazards are not available or feasible, actions to mitigate the welfare consequences caused by the identified hazards are discussed. In addition, it has been assessed whether specific categories of cattle or minority species related to cattle such as buffaloes might be subjected to specific hazards (ToR‐4).

Among the methods that are used worldwide for on‐farm killing, EFSA has applied the following criteria for the selection of stunning and killing methods to be included in this assessment:

all methods with described technical specifications known by the experts and not only the methods described in Council Regulation (EC) No 1099/2009, and

methods currently used for killing of cattle, and those which are still under development but are likely to become commercially applicable, and

methods for which the welfare aspects (in terms of welfare hazards, welfare consequences, ABMs, preventive and corrective measures) are described sufficiently in the scientific literature.

Applying these criteria will result in not including nor describing in this scientific opinion some practices, which may be applied worldwide.

The mandate also requests a list of methods, procedures or practices deemed unacceptable on welfare grounds. Regarding this request, the Panel is aware of two issues. Firstly, it has to be noted that some methods, procedures or practices under question cannot be subjected to a risk assessment procedure, because there is no published scientific evidence relating to them. Secondly, although scientific risk assessment can support discussions on what practices are acceptable or unacceptable on welfare grounds, the ultimate decisions on acceptability involve e.g. ethical and socioeconomic considerations that need to be weighed by the risk managers.

In response to this request, therefore, the Panel listed practices for which welfare consequences were identified and classified as ‘severe’. To do so, expert knowledge was elicited, and the available scientific evidence was assessed in order to subdivide practices into two groups, namely the group of those leading to ‘severe’ welfare consequences and the group of those not leading to ‘severe’ welfare consequences. For the practices leading to severe welfare consequences, the Panel identified serious welfare concerns and therefore recommends that these practices should be avoided, redesigned or replaced by other practices, leading to better welfare outcomes. These practices are discussed in this scientific opinion.

2. Data and methodologies

2.1. Data

2.1.1. Data from literature

Information from the papers selected as relevant from the literature search (LS) described in Section 2.2.1 and from additional literature identified by the WG experts was used for a narrative description and assessment to address ToRs 1, 2, 3 and 4 (see relevant sections in the Assessment section).

2.1.2. Data from expert opinion

The data obtained from the literature were complemented by WG experts’ opinion in order to identify hazards’ origins, welfare consequences, ABMs and preventive and corrective measures relevant for the current assessment.

2.2. Methodologies

Two main approaches were used to develop this scientific opinion: (i) literature search and (ii) expert opinion through WG discussion.

The general principle adopted was that, when scientific literature supporting the text is available, the relevant reference/s are cited in the body of the document. When no published information is available, expert opinion was used.

2.2.1. Literature search

A literature search was carried out to identify hazards related to animal welfare during on‐farm killing of cattle in peer‐reviewed and grey literature.

Restrictions were applied in relation to the date of publication, considering only those records published after a previous EFSA scientific opinion on the topic (EFSA, 2004).

A total of 20 references were retrieved and reviewed by the WG members until a final subset of seven relevant references was selected and considered in this assessment by reviewing the full papers.

Full details of the literature search protocol, strategies and results, including the number of the records that underpin each process, are provided in Appendix A to this scientific opinion. In addition, the experts in the WG selected relevant references starting from scientific papers, including review papers, books chapters and non peer‐reviewed papers known by the experts themselves or retrieved through non‐systematic searches, until the information of the subject was considered sufficient to undertake the assessment. When needed, relevant publications before 2004 were considered.

2.2.2. Risk assessment methodology and structure of the scientific opinion

The working group experts followed the risk assessment methodology from the EFSA's guidance on risk assessment in animal welfare (EFSA AHAW Panel, 2012b).

Based on expert opinion through working group discussion, the WG experts firstly described the phases and the related processes of killing on farm and specifically which killing methods should be considered for the current assessment.

Using the available literature and their own knowledge, the experts then produced a list containing the possible welfare consequences characterising each process related to the on‐farm killing of cattle. To address the ToRs, the experts then identified the hazards leading to those welfare consequences and their origin (ToR‐1) and the related preventive and corrective measures (ToR‐3); this was also done for specific animals categories (ToR‐4). ABMs for measuring the welfare consequences were identified (ToR‐2). Measures to mitigate the welfare consequences were also considered.

It should be noted that ToR‐1 of the mandate asks to identify the origins of the hazards in terms of staff or facilities/equipment. When discussing the origins, it was considered necessary to explain them further by detailing what actions of the staff or features of the equipment and premises that can cause the hazard. Therefore, for each origin category (staff, premises/equipment), relevant origin specifications have been identified by expert opinion.

Related to the structure of the scientific opinion, chapters are organised by Phase 1 ‘Handling and moving’ and Phase 2 ‘Killing’ (i.e. restraining and application of stunning and killing method). In Phase 1, welfare consequences and hazards are presented in a list for the process ‘Handling and moving’ and hazards are included within the related welfare consequences. Within Phase 2, subchapters are organised by killing methods and welfare consequences are common for all stunning methods. Instead, hazards are specifically listed within each stunning method.

2.2.3. Development of outcome tables to answer the ToRs

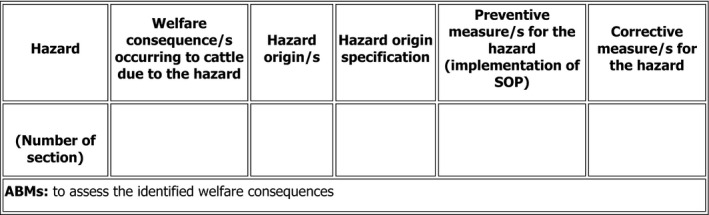

The main results of the current assessment are summarised in tables (so‐called outcome tables, see Figure 1 below).

Figure 1.

Example of the structure of an outcome table

The outcome tables link all the mentioned elements requested by ToRs 1, 2 and 3 of the mandate and provide an overall outcome for each process of killing in which all retrieved information is presented concisely (see description of the structure below and, for details, the specific Outcome Tables at the end of each process). Conclusions and recommendations of this scientific opinion are mainly based on the outcome tables.

The outcome tables have the following structure and the following terminology should be referred to:

‘OUTCOME TABLE’: Each table represents the summarised information for the processes described in the assessment (see at the end of the Chapter dedicated to each process; Section 3.1, Assessment).

‘HAZARD’: the first column in each table, the first column reports all hazards pertaining to the specific process related to on‐farm killing of cattle; the number of the section where each hazard is described in detail is reported in brackets. For each hazard, the individual row represents the summarised information relevant to the elements analysed for that hazard. Therefore, it links between an identified hazard, the relevant welfare consequences, origin/s of hazards and preventive and corrective measures (see example in Figure 1).

‘WELFARE CONSEQUENCES OCCURRING TO THE CATTLE DUE TO THE HAZARD’: this column lists the welfare consequences to the cattle of the mentioned hazards.

HAZARD ORIGIN: this column contains the information related to the category of hazard origin, which can be staff‐, equipment‐ or facility‐related. Most hazards can have more than one origin. HAZARD ORIGIN SPECIFICATION: this column further specifies the origin of the hazard namely, what actions of the staff or features of the equipment and facilities can cause the hazard. This information is needed to understand and choose among the preventive and corrective measures.

PREVENTIVE MEASURE/S OF THE HAZARD: depending on the hazard, origin/s several measures to prevent the hazard are proposed. They are also elements for implementing SOP.

CORRECTIVE MEASURE/S OF THE HAZARD: in this column practical actions/measures for correction of the mentioned hazard are proposed. These actions relate to the identified origin of the hazards.

ANIMAL‐BASED MEASURES: the bottom row lists the feasible measures to be performed on the cattle to assess the welfare consequences of a hazard.

2.2.4. Uncertainty analysis

The outcome tables include qualitative information on the hazards and related elements identified through the methodologies are explained in Section 2.2.3.

When considering the outcome tables, uncertainty exists at two levels: (i) related to the completeness of the information presented in the table, namely to the number of rows within a table (i.e. hazard identification) and (ii) related to the information presented within a row of the table (i.e. completeness of hazard origins, preventive and corrective measures on the one side, and welfare consequences and ABMs on the other side).

However, owing to the limited time available to develop this scientific opinion, an uncertainty analysis for the latter level was not be conducted, but only for the first level, i.e. for the hazard identification process.

In such a process of hazard identification, uncertainties may result in false‐negative or false‐positive hazard identifications:

Incompleteness (false negative): Some relevant welfare related hazards may be missed in the identification process, and so will be considered non‐existent or not relevant.

Misclassified (false‐positive): Some welfare‐related hazards may be wrongly included in the list of hazards of an outcome table without being a relevant hazard.

Incompleteness (false negatives) can lead to under‐estimation of the hazards with a potential to cause (negative) welfare consequences.

The uncertainty analysis was limited to the quantification of the probability of occurrence of false‐negative or false‐positive hazards. Uncertainty regarding probability of occurrence of false‐negative hazards can relate to (i) the situation under assessment i.e. limited to the on‐farm killing practices considered in this assessment according to the three criteria described in the Interpretation of ToRs (see Section 1.2) or (ii) the global situation i.e. including all possible variations to the on‐farm killing practices that are employed in the world, and that might be unknown to the experts of the WG. The Panel agreed it was relevant to distinguish the false‐negative hazard identification analysis for these two cases.

For false‐negative hazard identification, the experts elicited the probability that at least one hazard was missed in the outcome table. For false‐positive hazard identification, the experts elicited the probability that each hazard included in the outcome table was correctly included (i.e. it was a ‘true positive’ hazard).

For the elicitation, the experts used the approximate probability scale (see Table 1) proposed in the EFSA uncertainty guidance (EFSA, 2019). Individual answers were then discussed, and a consensus judgement was elicited.

Table 1.

Approximate probability scale (see EFSA, 2019, Table 4)

| Probability term | Subjective probability range | Additional options | |

|---|---|---|---|

| Almost certain | 99–100% | More likely than not: > 50% |

Unable to give any probability: range is 0–100% Report as ‘inconclusive’ cannot conclude, or ‘unknown’ |

| Extremely likely | 95–99% | ||

| Very likely | 90–95% | ||

| Likely | 66–90% | ||

| About as likely as not | 33–66% | ||

| Unlikely | 10–33% | ||

| Very unlikely | 5–10% | ||

| Extremely unlikely | 1–5% | ||

| Almost impossible | 0–1% | ||

3. Assessment

3.1. Introduction to on‐farm killing practices

There are several reasons for killing cattle on farms for other purposes than slaughter (i.e. killing cattle for human consumption). Two main categories can be identified: large‐scale killing (or depopulation) and killing individual animals or small groups (euthanasia or emergency killing). On‐farm conditions differ from regular slaughterhouses, especially during the killing for disease control reasons due to lack of handling and restraining facilities for the purpose. This also implies that various killing methods on farms may not always be as efficient as in slaughterhouses. Additionally, when it concerns infectious diseases control, the required speed of action places extra pressure on personnel (Gerritzen and Raj, 2009). Contrary to the killing of poultry or pigs, all available killing methods are individual, and there is no existing method for killing of groups of cattle on‐farm.

AVMA (2020) recommends the following methods for on‐farm killing of cattle: barbiturates and barbituric acid derivatives, firearms, penetrative captive bolt and non‐penetrative captive bolts (for calves only). The outcome of the main killing methods applied on‐farm can be achieved by a two‐step process involving application of a stunning method immediately followed by a killing procedure, or by application of a one‐step killing method (Table 2). At the present time, an adjunctive method such as exsanguination, pithing or the lethal injection of a saturated solution of potassium chloride is recommended to ensure death when penetrative captive bolt stunning or another reversible stunning method is used.

Table 2.

Methods used for on‐farm killing of cattle and animal categories

| Method | Animal category |

|---|---|

| Penetrative captive bolt followed by killing method (two steps) | All |

| Non‐penetrative captive bolt followed by killing method (two steps) | Calves up to 3 months |

| Firearm (one step) | All |

| Lethal injection (one step) | All |

| Electrocution (head‐only stunning immediately followed by cardiac arrest with a second current cycle or bleeding) (two steps) | All |

3.1.1. Large‐scale killing of cattle: main reasons and planning of killing

Large‐scale killing on farm or depopulation of cattle may be necessary for several reasons: for the control or eradication of certain animal diseases, to deal with a natural disaster situation such as flood, storm, fire, severe drought and earthquake, as an emergency intervention during feed contamination, as an economic mitigation measure during oversupply or closed marketing channel, foreclosure of the farm, outbreak of a highly contagious disease among human population and, as a consequence, closure of slaughterhouses or movement restriction (e.g. SARS, COVID‐19), or to decrease the risk of a zoonotic disease infecting humans (FAWC, 2012).

Indeed, contingency plans exist in most countries to deal with disease outbreaks (e.g. AUSVETPLAN, 2015; DEFRA, 2019), but they do not necessarily include natural disasters such as floods. Nevertheless, Gavinelli et al. (2014) have suggested scenario planning, which is a method of preparing for plausible future events during an outbreak, that allows planners to anticipate the problems, re‐evaluate their assumptions and reflect on the consequences of alternatives when developing more resilient strategies. Gavinelli et al. (2014) have suggested considering animal welfare impacts during scenario planning to include, among other aspects of leadership and decision making, animal housing and farming environments, availability of killing methods and competent personnel.

In addition, Gavinelli et al. (2014) have suggested that when preparing the on‐farm plan, planners must ensure that it is important to assess the farm, in particular size and location, the species and age of animals, available handling facilities, accessibility of the farm and pens and potential obstructions. When choosing the killing method, key considerations are its capacity to kill the animals in a timely and controlled manner, its compatibility with restraint facilities, location on farm where it is being used and required services (e.g. electrical supply).

It is also important to ensure neonatal, sick and infirm animals are prioritised, restrained individually and killed in situ; animals likely to harm each other should be penned separately; and normal husbandry and feeding should continue up to the point of killing (Gavinelli et al., 2014).

3.1.2. Reasons for killing of individuals or of a small number of animals

Individual or small groups of cattle may have to be killed to end pain and suffering due to the lack of treatment options. Additionally, animals may be killed due to the likelihood of suffering in the immediate future and where remedial care is not considered possible or appropriate. The term euthanasia is also used in literature (e.g. FAWC, 2018; AVMA, 2020) to describe the act of inducing death using a method that causes a rapid and irreversible loss of consciousness and death with minimum pain and distress to the animal (OIE, 2018). In this scientific opinion, however, the term killing is used throughout.

In some countries, newborn male dairy calves may also be killed for economic reasons (Hötzel et al., 2014; Cuttance et al., 2017; Renaud et al., 2017).

3.2. Phase 1 – Handling and moving of cattle

Handling is the process of preparation of the animals for the killing, and sometimes, it involves moving the animals to the killing point. Gavinelli et al., 2014 lists animal handling among one of the key stages for monitoring on farm killing.

Handling and moving can be very stressful to cattle, especially when they are isolated out of their home pens. Animals that are sick or injured have difficulties to walk by themselves and should only be moved when there is no other option and with enough support to avoid suffering. Preferably, these animals should be killed in or close to their home pen. Also, for other reasons, like disease control depopulation, moving animals from their home pen should be avoided if possible to limit the spread of the pathogenic agent. Before animals are killed in their home pens, it should be assured that carcass removal for disposal is possible since removal of dead animals out of the home pens can be challenging (especially if large). When it is necessary to move animals to a killing area, they should only be moved from their home pens to the killing pen/point if it can be ensured that they will be killed without any delay.

Farm races are usually designed to handle adult cattle (see Figure 2), but these may be unsuitable for young calves.

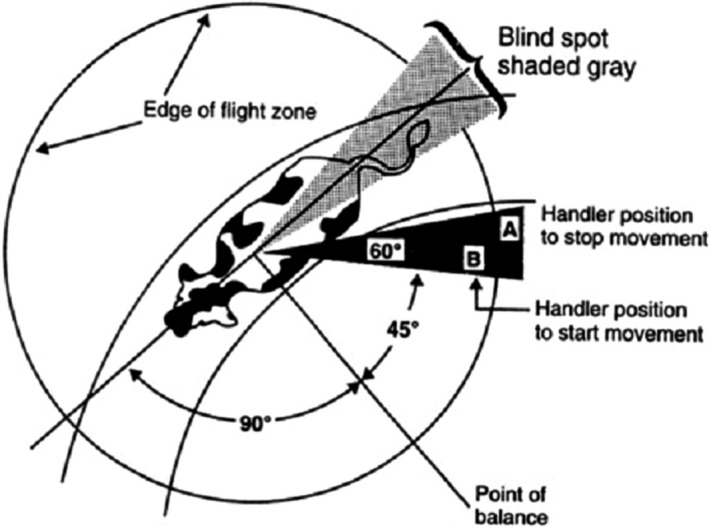

Figure 2.

Flight zone and point of balance when handling cattle (Source: Temple Grandin website16

When cattle have to be moved, handlers need to understand their behaviour; this will help to prevent pain (injuries) and fear in both animals and people. Cattle are a prey species, and fear motivates them to escape from perceived danger such as human handling (Moran and Doyle, 2015). When they become agitated during handling it is usually due to fear (see Section 3.2.2 for details). Fear‐based behaviour is likely to be the main cause of accidents due to cattle becoming agitated or refusing to move (Grandin, 1999). Some major causes of animal handling accidents according to Grandin (1999) are: (i) fearful, agitated animals; (ii) faulty equipment; (iii) male dominance aggression and (iv) maternal aggression.

Cattle should be moved as calmly as possible and allowed to progress freely together. Distractions causing them to baulk must be removed, and the destination pen should be sufficiently lit to attract them towards it (Gavinelli et al., 2014). It is preferable to move cattle in groups as they are gregarious animals. Pens, passageways and races shall be designed and constructed to allow the animals to move freely in the required direction using their behavioural characteristics and without distraction.

The behaviour of the animal handler has a crucial effect on cattle behaviour in this phase and on their welfare. A survey conducted by researchers at Oklahoma State University indicated that 50% of accidents when handling cattle were caused by human mistakes (Huhnke et al., 1997). Cattle should be handled quietly and firmly, using a plastic paddle, flags or streamers (affixed to long handles) to prevent the animals from turning back. Slapping and shouting cause agitation, sudden movements, baulking and panic. Electric goads should not be used (Grandin, 1999). Calm handling in an environment that has been designed with the cattle's perception of the world in mind will be less stressful to the cattle handler as well as to the animals (Grandin, 1999).

For example, cattle are more sensitive to high‐pitched sounds than people. The auditory sensitivity of cattle is greatest at 8 kHz, and the human ear is most sensitive at 100 Hz–3 kHz (Grandin, 1999). That means that noise should be avoided as much as possible since, even if it appears not frightening to humans, it can be for animals. This is specifically the case for high‐pitched sounds (Grandin, 1996) which, in the wild, are used as alarm calls. High‐frequency sounds activate the amygdala more effectively than low‐pitched sounds. People yelling at an animal may result in the animal becoming fearful and attempting to escape (Grandin, 1999).

Cattle have wide‐angle vision that enables themselves to see predators while grazing. Vision is their dominant sense and is responsible for about half of the sensory information they receive from their surroundings. Their visual field is 330 degrees and they have binocular vision for a limited area in front of them (Moran and Doyle, 2015). This is where they will have the clearest vision and ability to judge depth or distance. In order to get the best vision, cattle will lower their head and face towards the stimulus they want to explore. They have also a small blind spot directly behind them. Therefore, it is recommended not to approach cattle through their blind spot, or at least people handling cattle should talk calmly to avoid animals being surprised.

Handlers acting during on‐farm killing need to understand the flight zone (Figure 2; Grandin, 1999). The flight zone is the animal's safety zone, and its size varies depending on the animal's degree of wildness or tameness. When a person enters the flight zone, the animal will turn away. According to Grandin (1999), the size of the flight zone is determined by three factors, which are mainly related to animal characteristics: genetically determined traits (excitable vs. calm), amount of contact with people and the type of the contact with people (negative vs. positive) (Moran and Doyle, 2015; Simova et al., 2017). Therefore, moving and handling of animals by their owner or the person delivering care to them should be easier (if the quality of the contact is positive). When handled by an unknown person (e.g. during large‐scale killing), the handler has to adapt its behaviour following the characteristics of the animal (e.g. calm and tame or wild and excited).

3.2.1. Welfare consequence ‘Impeded movement’: assessment, hazard identification and management

Definition of ‘Impeded movement’:

Difficulty of movement due to inappropriate floors resulting in slipping and falling.

Animals not handled correctly or in poorly designed and maintained premises will experience impeded movement that can lead to pain when animals are slipping and falling.

ABMs for ‘Impeded movement’:

The assessment can be done by counting the number of slips and falls per animal. Definitions of slipping and falling are provided in Table 3.

Table 3.

ABMs for the assessment of ‘Impeded movement’ during handling and moving of the animals to the killing point

| ABM | Description | Welfare consequence |

|---|---|---|

| Falling | Loss of balance, in which part(s) of the body (beside legs) are in touch with the floor (Welfare Quality®, 2009) | Impeded movement |

| Slipping | Loss of balance, without (a part of) the body being in touch with the floor (Welfare Quality®, 2009) | Impeded movement |

Hazards leading to ‘Impeded movement’

The impairment of animal welfare at this stage can be mainly due to two hazards:

Improper design, construction and maintenance of the premises.

Inappropriate handling.

Improper design, construction and maintenance of the premises

If the raceway from the pen area to the killing point is not well designed (angle of the slope, type of floor etc.), constructed or maintained (slippery etc.), this could lead to impeded movement due to animals slipping or falling.

It is highly challenging to handle large animals safely when they are slipping on the floor or panicking because they are losing their footing. Slips and falls occur mostly when concrete floors are wet with rain, urine or manure and it occurs especially when cattle are running or turning. In any case, there should not be any steep inclination of the floor from the home pens to the killing area. But in case steep ramps are used, there is a risk of injury from both jumping, slipping and falling of animals (Sandstrom, 2009). It is considered inappropriate to use a ramp angle greater than 20° for calves or 26° for adult cattle (Faucitano and Pedernera, 2016).

If cattle slip and fall and are reluctant to move, it may increase inappropriate, rough handling, leading to additional fear and pain.

Inappropriate handling

It is considered inappropriate handling when people are forcing the animals to move too quickly or through raceways not adapted for them. Moving cattle in an inappropriate way may result in a greater incidence of slips and falls.

Inappropriate handling might cause animals rushing and getting scared and then slipping and falling during moving.

Prevention and correction of ‘Impeded movement’ and its related hazards

The preventing methods to avoid impeded movement are the following:

Floors should be clean, dry and non‐slippery.

It is recommended to move cattle in small groups (ideally of familiar animals) using flags, a plastic bag on a stick, streamers or a plastic paddle in order to ease handling and reduce occurrence of slipping and falling (Grandin, 2008).

Avoid right angles and too steep raceways (> 20° for calves or 26° for adult cattle) (Faucitano and Pedernera, 2016). When the slope is steeper than 10°, raceways should be equipped with foot battens or cleats which prevent animals from slipping while walking on the ramp, reducing the risk of falls (EFSA AHAW Panel, 2011). A 20 cm spacing between the cleats is recommended to ease cattle walking smoothly through the ramp (Grandin, 2014).

People involved in handling and moving and killing of animals at farm should have adequate knowledge and understanding of the species‐specific behavioural patterns as well as skills to perform the tasks allocated to them.

As corrective measures, the first step in improving animal movement is to correct mistakes that people make while handling and/or moving animals. The corrective recommendations should be (Grandin, 1999; Faucitano and Pedernera, 2016): (i) use the flight zone and the point of balance principle, (ii) stop the use of electric goads and use moving aids described above, (iii) use following behaviour and move the cattle in small groups.

Stopping obvious handling mistakes will make it possible to determine if the problems when moving and handling animal in a particular farm are due to people making mistakes or to a default in the design and/or maintenance of the raceway. It might happen often on farm that the raceway is built in an emergency context and therefore is not adequate. In that case, using adapted handling methods for moving cattle with a low speed can help reducing impeded movement.

3.2.2. Welfare consequence ‘Pain’ and ‘Fear’: assessment, hazard identification and management

Definitions of ‘Pain’ and ‘Fear’:

Pain: An unpleasant sensory and emotional experience associated with, or resembling that associated with, actual or potential tissue damage (Raja et al., 2020).

Fear: Emotional state induced by the perception of a danger or a potential danger that threatens the integrity of the animal (Boissy, 1995).

Fear motivates animals to avoid predators and to survive in the wild. Fearful large animals, like cattle, are dangerous animals. They are more likely to injure themselves or the handlers than unfearful animals. In case animals are not used to human contact or had negative experiences with humans in the past, being moved and handled can generate fear to them. Cattle can become extremely fearful and agitated when they are suddenly exposed to a new experience, which can be the case when one is trying to move the animals in a specially built raceway or chute in order to take them to the killing point. Similarly, animals raised in extensive systems usually have few contacts with people and are difficult to handle (Gallo and Huertas, 2016). Such animals will react differently to those raised indoors or in frequent contact with humans and, therefore, gathering and moving them to the killing area may expose them to fear and eventually pain. There are also some structural deficiencies at farm level, mainly due to inadequate design and poor maintenance of handling structures (pens, corrals, races, crates, ramps and others), which can increase the probability of animals experiencing fear.

In case animals are already injured (and then not handled in a specific way adapted to their body status), slip and fall or are hit by the staff, they will be submitted to pain, that could even be boosted by fear.

ABMs for ‘Pain’ and ‘Fear’ :

ABMs for pain and fear are injuries, lameness, escape attempts, vocalisations, reluctance to move and turning around or moving backwards.

Slipping and falling (see Section 3.2.1) can lead to injuries, leading to pain. Injuries can, however, also originate from the rearing period.

Cattle vocalise when they experience something aversive or threatening, and therefore, it can be used as an ABM for fear (Grandin, 1998, 2001). Reluctance to move, turning around or moving backwards are also signs of fear (Sandstrom, 2009; Welfare Quality®, 2009).

Pain and/or fear can be assessed during handling and moving by counting the animals with injuries or lameness and the occurrence (per animal) of escape attempts, vocalisations, reluctance to move and turning around or moving backward (see Table 4).

Table 4.

ABMs for the assessment of ‘Pain’ and ‘Fear’ during handling and moving of the animals

| ABM | Description | Welfare consequence |

|---|---|---|

| Injuries | Tissue damage (bruises, scratches, broken bones, dislocations) (EFSA AHAW Panel, 2012a) | Pain |

| Escape attempts | Attempts to go through, under or over gates and other barriers. Head and neck stretched forward and either held level with back or slightly raised above or below back line (modified after Lanier et al., 2001) | Fear |

| Vocalisations | An animal's vocalising response in terms of mooing, bellowing or roaring (modified after Grandin, 2012). Frequently referred to as distress vocalisation in the literature | Pain, fear |

| Reluctance to move | An animal that refuses to move when coerced by the operator or that stops for at least 4 s not moving the body and the head (freezing) (adapted from Welfare Quality®, 2009) | Pain, fear |

| Turning around or moving backwards | When an animal facing towards the restraint area turns around or moves backwards (adapted from Welfare Quality®, 2009) | Fear |

Hazards leading to ‘Pain’ and ‘Fear’

The impairment of animal welfare at this stage can be mainly due to five hazards appearing either alone or combined:

Inappropriate design, construction and maintenance of premises

Inappropriate handling

Moving cattle from a group into a single line into the restraint

People entering the pen/rearing area

Unexpected loud noise

Inappropriate design, construction and maintenance of premises

Improper design, construction and maintenance of premises are major hazards, which may cause fear, and possibly pain. In a study in South America, Gallo and Huertas (2016) showed that problems are mainly due to structural deficiencies at farm level, and to inadequate design and poor maintenance of handling structures (pens, corrals, races, crates, loading ramps and others).

Handling problems due to hesitation and refusal of cattle to go forward can also be caused by for example poor lighting, distracting objects, such as moving chain, shining reflections off metal, sparkling water puddles, people up ahead, a coat hung on a fence, object on the ground, shadows, a change in flooring type or texture, a drain grate or air hissing (Grandin, 1996, 1999). If the raceway is not well designed (lighting, presence of shadows, distractions) or maintained, this could lead to fear and the reluctance of animals to move, and hence, the operator resorting to rough handling causing pain.

Inappropriate handling

Moving cattle in an inappropriate way that causes pain and/or fear results in balking, refusing to move forward, turning around or backing up in the raceway. When animals are acting in this way, employees are more likely to use force and harsh methods such as multiple shocks with electric goads to move them (Grandin, 2016).

Bad practices used to get the animals to move were reported by Gallo and Huertas (2016) to be common in South America, but they occur elsewhere on the globe. In certain situations, there is a tendency to use aggressive strategies to drive animals and inappropriate aids (sticks, goads, shouting and sometimes even unsuitable handling practices that are described by the OIE (2013)).

People entering the pen

People entering the house/pen is unavoidable and essential to handle and/or move animals. However, awareness of the species‐specific behaviour of cattle (Grandin, 1996) may modify the behaviour of the handler and reduce fear (see section on handling above)

Unexpected loud noise

Defined as a noise that by its level and/or its suddenness induces fear in the animals.

Loud or distracting noises originate mainly from machines, gates clanging and from cattle and personnel shouting. Vocalisations of stressed cattle and human shouting, which is particularly abhorrent for animals (Weeks, 2008), are stressful. Excessive noise is one cause of animal agitation.

Prevention and correction of ‘Pain’ and ‘Fear’ and their related hazards

To prevent pain and fear related to moving and handling of cattle, it is advised to kill animals in or close to their home pen if possible. When deciding on the killing methods to be applied, this should be taken into consideration. This might include using firearms, when cattle are untamed and living extensively.

A long‐term prevention should be for the farmer to train animals to be handled and moved.

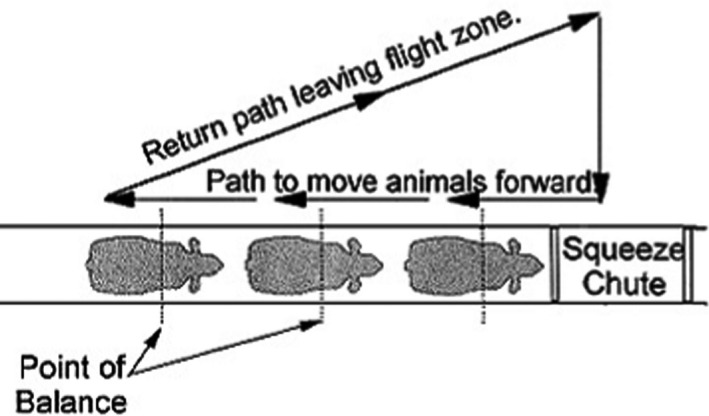

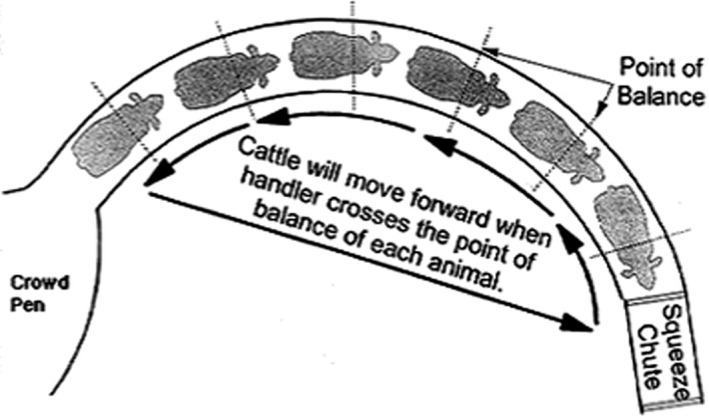

When handling and moving the animals the handler needs to use the flight zone principle (see Figure 2) as well as the point of balance in order to avoid inappropriate handling. The point of balance is an imaginary line at the animal's shoulders. To induce the animal to move forward, the handler must be behind the point of balance. To make the animal move backward, the handler must be in front of the point of balance. Cattle will move forward when a handler walks past the point of balance in the opposite direction of desired movement (Figures 3 and 4).

Figure 3.

This movement pattern can be used to induce an animal to move into a squeeze chute or a raceway. The handler walks inside the flight zone in the opposite direction of desired movement (Grandin, 1999)

Figure 4.

Handler movement pattern to use in a curved corridor or raceway system. The techniques here and in Figure 3 make it possible to avoid rough handling (Grandin, 1999)

Handling is safer when animals are moved quietly. Handlers should avoid yelling and flapping their arms, because this may agitate the animals. Use of electric goads increases animal agitation, as well as hazards to handlers and therefore should be avoided.

When people are entering the pen, attention should be paid so that the handler is not constantly invading the animal's flight zone (Grandin, 1999). The animals should have space to move away.

Constructing raceways with a minimum of distracting obstacles or factors will help to move animals at a normal speed without impeded movement, pain or fear. This is an example of using behavioural principles to control the animal, instead of force.

Attention should be paid to light, since animals may refuse to enter a dark place (Grandin, 1999). Use bright, diffuse lighting facilitates animal movement. Lamps can be used to attract animals into raceways and chutes, but the light should not glare directly into their eyes. When handling facilities are located inside a building, translucent plastic panels can be installed to admit diffuse, shadow‐free light.

Distractions can cause animals to baulk and refuse to move when being handled and moved. In order to adapt the raceway configuration, it should be observed at a cow's eye height (Grandin, 1999). Some of the things to look for and remove prior to animals coming are (Grandin, 1996): moving chains, shining reflections off metal, sparkling water puddles, people up ahead, dripping water, a coat hung on a fence, objects on the ground, shadows, a change in flooring type or texture, a drain grate.

It is important to limit unexpected and intermittent loud noises, because they lead to fear and decrease coping capacities. It is especially important to reduce high‐pitched noise. The preventive measures will consist in staff education and training (i) to make them aware that noise at the cattle's level should be avoided, and (ii) to make them avoid shouting and making noise with the equipment and facilities, and identify and eliminate the sources of noise. Facilities should be constructed to minimise noise. Pad gates with rubber stops to prevent clanging and banging can be used.

A first corrective measure is to correct mistakes that people make while handling and/or moving animals and that frighten the animals. The corrective measures would be (Grandin, 1999; Faucitano and Pedernera, 2016): (i) use the flight zone and the point of balance principle, (ii) stop the use of electric goads and use moving aids described above, (iii) use following behaviour and move the cattle in small groups instead of a single line or individually.

If an animal rears, people should back off and step out of the animal's flight zone. When people back away, the animal often settles back down. Handlers should never attempt to push a rearing animal; this is likely to increase its agitation and may cause an accident (Grandin, 1999). When cattle become agitated and fearful, up to 20 min is required for their heart rate to return to normal (Grandin, 1999). In case cattle gets agitated it should be given an opportunity to calm down before continuing handling and moving. It might happen often on farm that the raceway or chute is built in an emergency context and therefore is not adequate. In that case, using adapted handling methods for moving cattle with a low speed of moving can help reducing fear. In case of unexpected loud noise frightening the animal, personnel should suppress immediately the source of noise.

3.2.3. Outcome table on ‘handling and moving’ of cattle

Table 5.

Outcome table on ‘handling and moving of cattle’

| Hazard | Welfare consequence/s occurring to the cattle due to the hazard | Hazard origin/s | Hazard origin specification | Preventive measure/(implementation of SOP) | Corrective measure |

|---|---|---|---|---|---|

| People entering the pen/rearing area | Fear | Staff | Requirement for the process | None (unavoidable as part of the method) | Minimise disturbance |

| Inappropriate handling | Pain, fear, impeded movement | Staff, facilities, equipment | Lack of skilled operators, operator fatigue, rushing, lack of dedicated handling facilities and restraint, time pressure, lack of appropriate driving aids |

Training of staff for proper handling; staff rotation, appropriate equipment and facilities to move animals (e.g. temporary passage or race ways) Slow down the process |

Take necessary action, use the balance point/flight zone concept to drive animals, act calmly |

| Unexpected loud noise | Fear | Staff, facilities, equipment | Staff shouting, machine noise, equipment noise | Staff training, avoid personal shouting, do not operate noisy machines and equipment in the animal handling area | Identify and eliminate the source of noise, stop shouting |

| Improper design, construction and maintenance of premises | Pain, fear, impeded movement | Staff, facilities | Inadequate preparation of the premises by staff; inappropriate lighting, distractions, improper construction (slope, slippery floor, angles, open‐side raceways) | Ensure proper design, construction and maintenance of the area, ensure there are no distractions | Stop continuing movement of animals and take necessary action before resuming |

| ABMs: injuries (pain), vocalisations (pain, fear), escape attempts, reluctance to move, turning around or moving backwards (fear), slipping and falling (impeded movement) | |||||

3.3. Phase 2 – Killing

3.3.1. Introduction

Several guidelines provide instructions to achieve effective killing (e.g. HSA, 2017; AVMA, 2019). On‐farm killing should cause loss of consciousness followed by death without pain or fear. The killing phase includes both the restraint and the killing process. The killing of the animal can be performed by one step or two step methods. Restraint will be described in each method and ‘restraint’ means the application to an animal of any procedure designed to restrict its movements sparing any avoidable pain and minimising fear in order to facilitate effective killing.

3.3.1.1. Welfare consequences ‘Pain and fear’ and related ABMs

‘Pain’ and ‘Fear’ are defined in Section 3.2.2.

Cattle might experience pain and fear during restraining for killing, and therefore, the duration of restraint should be as short as possible. As a guide to good animal welfare practice, cattle should be restrained only when the operator is ready to kill the animal. ABMs related to pain during restraint are vocalisations, escape attempts and injuries. ABMs related to fear during restraint are escape attempts and vocalisations. For details, the ABMs related to restraint are described in full in Table 6.

Table 6.

ABMs for the assessment of ‘Pain’ and ‘Fear’ related to restraint during killing of the animals

| ABM | Description | Welfare consequence |

|---|---|---|

| Vocalisations | An animal's vocalising response in terms of mooing, bellowing or roaring (modified after Grandin, 2012). Frequently referred to as distress vocalisation in the literature | Pain, fear |

| Escape attempts | Attempts to go through, under or over gates and other barriers. Head and neck stretched forward and either slightly raised above back, slightly lowered or level with back (modified after Lanier et al., 2001) | Pain, fear |

| Injuries | Tissue damage (bruises, scratches, broken bones, dislocations) (EFSA AHAW Panel, 2012a) | Pain |

Furthermore, ineffective stunning will lead to persistence of consciousness. Recovery of consciousness might also occur in effectively stunned animals if the animals are not dead or when a killing method is not performed in time or was not properly done. Both these situations will also cause pain and fear to animals and are considered an important animal welfare concern in the on‐farm killing process.

Consciousness is defined as the capacity to receive, process and respond to information from internal and external environments and therefore the ability to feel emotions and being sensible to external stimuli, leading to pain and fear (Le Neindre et al., 2017).

Signs of consciousness are specific for each killing method (EFSA, 2004). ABMs related to consciousness are described in EFSA AHAW Panel (2013), which reports a toolbox for several killing methods.

Depending on the killing method, consciousness can be recognised by the failure to collapse or the absence of loss of posture, the absence of tonic–clonic seizures and the presence of normal breathing (including laboured breathing), and, in extreme cases, animals may also vocalise. Conscious animals and those recovering consciousness will show also spontaneous blinking or positive eye reflexes (palpebral, corneal and pupillary). Head righting (attempt to raise head) after stunning and body arching during bleeding are also signs of consciousness.

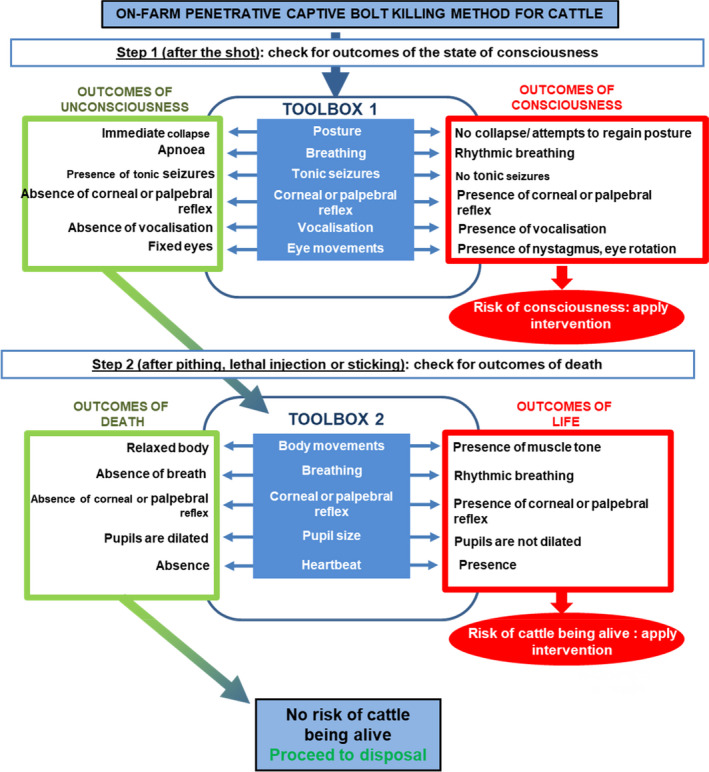

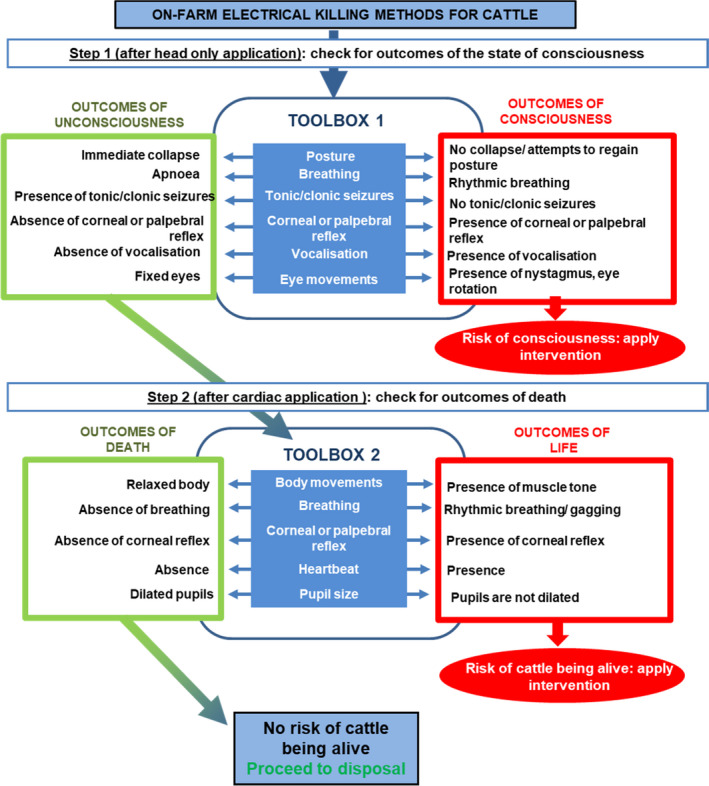

For each killing method flowcharts presenting the ABMs to recognise the presence of consciousness or life, are provided in the respective Sections.

In case of signs of consciousness or signs of life, an appropriate back‐up stunning or killing method should be applied immediately (see Section 3.3.2.2) to mitigate the welfare consequences.

Death should be monitored and confirmed after applying the killing method and before disposal of the carcasses.

3.3.2. Penetrative captive bolt stunning followed by a second step killing method

Penetrative captive bolt stunning involves firing of a retractable bolt on the skull of the animal to induce brain concussion leading to immediate loss of consciousness.

In order to shoot the captive bolt in the correct position, the animals need to be restrained. Restraint can take place in fixed or mobile crushes and pens, or with chemical sedation (e.g. xylazine) (Gerritzen and Gibson, 2016).

There is limited guidance on specific methods of restraint for the different categories of animals (calves, cows, bulls) and other bovines such as buffalos (European Commission, 2017).

Restraint of cattle in a crush or a narrow pen allows easy access to the head with minimal discomfort for the animal. However, for some animals, the head needs also to be restrained for effective stunning (European Commission, 2017).

Most of the farms will have a cattle crush used for veterinary examination or weighing machine, and these can be modified to restrain for stunning and facilitate removal of unconscious animals after stunning. Cattle should not be restrained unless the operator is ready to apply the stunning method. If mechanical restraint is not available, cattle may be restrained using head halters with quick release knots.

Head collar and lead rope, halter or bridle are secured to restrict movement of the head. All halters, head collars used to restrain or handle cattle should be fitted with a method of quick release in case the animal becomes entangled in the equipment. These methods induce minimal discomfort for the animal and enable stabilising the head for stunning, including those cattle that cannot be moved from the pen or cannot rise, and need to be stunned where they are.

Young calves might be restrained manually by holding them against a wall or fence. However, this method can cause discomfort to the animal and might not be safe for the operator.

Calves are often fed from communal troughs where it is possible to stall and restrain them while feeding.

Penetrative captive bolt powered by cartridge is the most commonly used method to stun/kill cattle on farms (Shearer, 2018). The guns are designed to fire a retractable steel bolt that penetrates the cranium and enters the brain. The impact of the bolt on the skull results in brain concussion and immediate loss of consciousness (EFSA, 2004). Penetration of the bolt into the skull and subsequent withdrawal causes structural damage to the brain due to cavitation, which results in marked subarachnoid and intraventricular haemorrhages, especially adjacent to the entry wound and at the base of the brain. The bolt diameter and the strength, velocity and penetration depth are important parameters to ensure efficacy of the stun. If the diameter of the bolt is too narrow and sharp (like a nail), the bolt would easily penetrate through the skull and brain tissue without delivering the amount of kinetic energy required to inducing brain concussion. A thicker bolt (e.g. 7 mm) with blunt edge on the other hand would transfer more energy to the skull upon impact and also cause more severe structural damage to the brain during penetration and retraction. Existing recommendations on bolt velocities are based on abolition of evoked electrical activity in the brain: for steers, heifers and cows 55 m s‐1 and for bulls 72 m s‐1 (EFSA, 2004). The length of the bolt and thereby the penetration depth into the skull should be appropriate to the size of the cattle as recommended by the manufacturers. For example, Kline et al. (2019) investigated the effects of three different captive bolt lengths of 15.2 cm, 16.5 cm and 17.8 cm on the amount of brain tissue damage and hind limb kicking in cattle slaughterhouses. The air line pressure setting was 1,378.95–1,447.90 kPa for all captive bolts. Results of this study showed that all the test cattle (n = 45) were rendered immediately unconscious with a single shot; however, visual appraisal of the brains on the split heads indicated that the shortest bolt caused the least amount of brain damage. There was a trend (p = 0.06) for less kicking to occur when the 16.5 cm length bolt was used in the stunner. This finding is relevant to on‐farm stunning also, as kicking could interfere/hinder with the application of a secondary killing procedure if required.

Some guns have a captive bolt that protrudes from the muzzle when it is in the primed position and some others have a bolt that is recessed within the muzzle. Normally, when a bolt is fired, it requires a short distance to reach its maximum velocity before impacting on the skull. Therefore, guns with protruding bolts should be held slightly (up to 5 mm) away from the animal's head, whereas guns with recessed bolts must always be pressed firmly against the head. Captive bolt length and power of cartridges should be selected according to the manufacturer's instruction to suit the size of the animal.

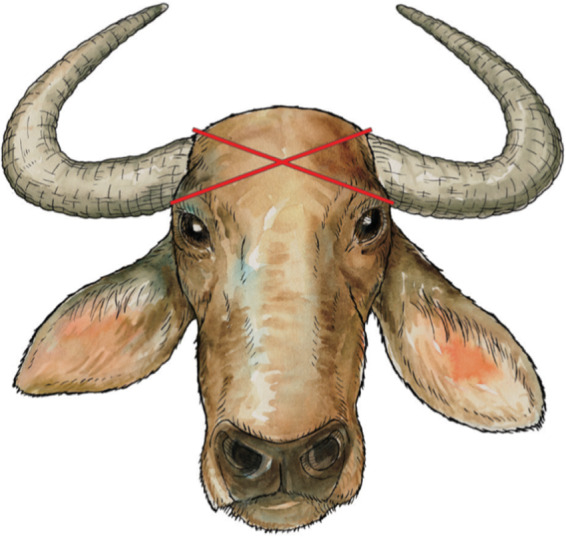

Various factors such as anatomical differences due to breed, sex or age of the animal, choice of the captive bolt gun and its maintenance, cartridge strength and its condition, shooting position and type of restraint used determine the effectiveness of stun. The ideal stunning position is in the middle of the forehead at the crossing point of two imaginary lines drawn between the eyes and the centre of the base of the opposite horns (HSA, 2016a).

The bolt parameters, i.e. velocity, exit length (depth of penetration into the skull) and diameter are determinants of the effectiveness of stun, i.e. depth of brain concussion. Ineffective stunning will occur due to low cartridge power, low bolt velocity, shallow penetration, too narrow bolt diameter and faulty equipment (EFSA, 2004). Minimum recommended bolt velocities are 55 m/s for steers, heifers and cows and 72 m/s for young bulls. Normally, recommended bolt diameter is a minimum of 7 mm and recommended penetration depth is at least 9 cm. Cartridges vary in strength and are classified according to the amount of propellant (gun powder) they contain, with 3.0 grain and 4.0 grain for large cattle and mature bulls (1 grain = 0.0648 grams). It is important to refer to the manufacturers’ instructions so that the correct cartridges are used for each model of stunner; they are identified by calibre (0.22 or 0.25), colour and headstamp (HSA, 2016a). Captive bolt equipment powered by compressed air works exactly the same as the cartridge fired equipment, but the energy is supplied via a high‐pressure compressor. The air line pressure may vary between 160 and 190 PSI (1,103.16 kpa and 1,310 kpa, respectively); higher pressures (1,448 kpa) have been reported in the literature (Martin et al., 2018; Kline et al., 2019). Most commercial slaughterhouses use a standard captive bolt length of 15.2 cm for pneumatic stunners in which only 9.02 cm of the bolt actually penetrates into the animal's skull (Kline et al., 2019). Longer bolts (16.5 cm and 17.8 cm) are used in order to induce more brain damage and increase the effectiveness of the stun but also increase the prevalence and intensity of post stun convulsions (Martin et al., 2018; Kline et al., 2019). Wagner et al., 2019 reported that the longer bolt length inflicted more visible damage to the brain. Oliveira et al., 2018 reported that pneumatically powered penetrating captive bolt resulted in immediate collapse, indicative of effective stunning, in 99% of cattle. Gibson et al. (2019) reported that shooting bulls with a pneumatic penetrating captive bolt was 100% effective on the basis of EEG parameters indicative of unconsciousness. In both these studies, an air line pressure of 220 psi (1,517 kPa) was used to fire the captive bolt gun.

Gilliam et al. (2014) reported that approximately 10% of animals required a secondary procedure to cause death. In that study, a single shot with penetrating captive bolt resulted in the death of 28/31 (90%), 17/19 (89.5%) and 8/10 (80%) adult, young and neonate, respectively. Specific reasons for the failure of penetrating captive bolt to cause death include insufficient depth of penetration of the bolt, differences in the resistance to bolt penetration related to hardness and thickness of the skin and skull and the potential for slight misdirection of the shot. Gilliam et al. (2012, 2014, 2018) also found notable differences between shot placement locations and breed characteristics.

Death may occur depending on the degree of injury to the brain, but is not a guaranteed outcome (Lambooij and Algers, 2016). Therefore, captive bolt stunning shall be followed as quickly as possible by bleeding and destruction of the brain and upper spinal cord by pithing or by a lethal injection.

Bleeding of cattle may be performed by severing the carotid arteries or brachiocephalic trunk. Delay in bleeding can occur when stunned animals convulse excessively, or when it is difficult to eject the animal from the restraint because of the position in which it has collapsed and it is lying in the restraint. Bleeding of captive bolt‐stunned cattle will not be a preferred during killing for disease control and pithing with disposable rods is the best and reliable option (Appelt and Sperry, 2007).

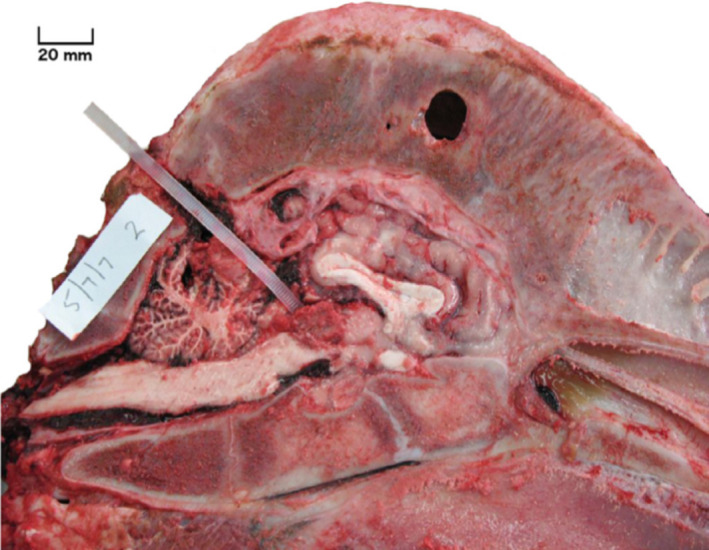

Pithing involves inserting a flexible wire or polypropylene rod through the bolt hole in the head made by a penetrative captive bolt (Figure 5). The movement of the rod destroys the brainstem and upper spinal cord, ensuring death and reduces the reflex kicking (convulsions) which can occur after stunning. Size of the pithing rod should be appropriate to the size of the cattle, i.e. long enough to reach the upper spinal cord.

Figure 5.

Illustration of pithing in cattle (source: Canadian Veterinary Medical Association)

Inserting a pithing rod through the bolt hole and destruction of the neural tissue in unconscious animals causes convulsions that are aesthetically unpleasant and therefore educating the people who are not familiar with the physiology of stunning and pithing is vital to avoid misconceptions about the humaneness of the procedure or psychological trauma of the staff.

Administration of a lethal injection is considered to be another secondary killing procedure that could be used to kill unconscious cattle after effective captive bolt stunning. In this regard, intravenous administration of an anaesthetic drug or saturated solution of potassium chloride may be used (AVMA, 2020).

Routine monitoring of the welfare outcome immediately after captive bolt stunning and pithing should be carried out using indicators presented in the flowchart (Figure 6). It is worth noting that heartbeat may continue for several minutes after effective pithing, and therefore, other indicators such as dilated pupils and absence of breathing may be used to assess the outcome immediately after pithing.

Figure 6.

Flowchart including indicators for the monitoring of state of consciousness and death of cattle following penetrative captive bolt stunning

3.3.2.1. Hazard identification for ‘Penetrative captive bolt stunning followed by a killing method’ leading to ‘Pain and fear’

The hazards identified during this process are:

Restraint

Incorrect shooting position

Incorrect captive bolt parameters

Overheating of the gun

Prolonged stun‐to-kill interval

Incomplete sectioning of the blood vessels

Ineffective pithing

Sublethal dose of chemical

Disposal of cattle while alive

These hazards can lead to the welfare consequence of pain and fear and can lead to failure in onset of unconsciousness or recovery before death occurs.

Restraint

Limiting movements forward, backwards and sideways movements to restraint will carry the risk of pain and fear.

Incorrect shooting position

Firing a captive bolt away from the recommended shooting position leads to ineffective stunning and pain due to the impact of the bolt on the skull. When the shooting position is more than 2 cm from the ideal position, there is a greater risk of a shallow depth of concussion (Gregory et al., 2007). Captive bolt guns can be either trigger or contact fired. With contact fired guns, there is no possibility to correct the position of the gun once it touches the head of the animal. Incorrect position can be due to the lack of skilled operators or fatigue, poor restraint and wrong target area or angle of shooting.

Incorrect captive bolt parameters

The bolt parameters (velocity, exit length and diameter of the bolt) fail to effectively stun and render them immediately unconscious. It may be caused by e.g. low cartridge power, low bolt velocity, shallow penetration and faulty equipment (too narrow bolt diameter). If the bolt is too narrow, or the velocity is too low, there will not be enough energy transfer to the head to induce effective stunning (EFSA, 2004). The cartridges used should be those recommended for the equipment by the manufacturer (HSA, 2016a).