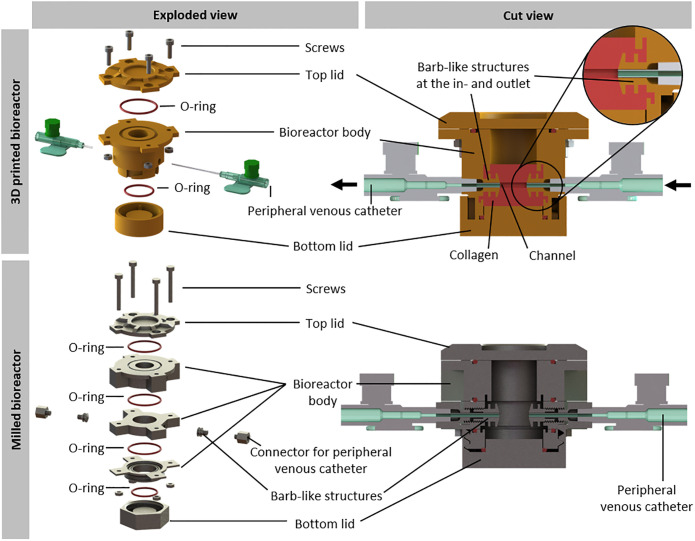

Fig 8. Comparison of 3D printed and milled bioreactor system for the culture of perfused hydrogels.

Overview of the 3D printed and the milled bioreactor. Both bioreactors are closed with a top lid and a bottom lid, sealed via O-rings. The bottom is connected to the bioreactor via a plug connection, whereas the top lid is fixed with screws. In contrast to the 3D printed bioreactor, the milled bioreactor consists of nine parts. The bioreactor body has two opposing inlets to hold two peripheral venous catheters for perfusion. Barb-like structures protrude inwards from the openings to anchor the hydrogel. For the 3D printed bioreactor the barb-like structures are part of the bioreactor body. For the milled bioreactor they are screwed into the openings as well as the connectors for the peripheral venous catheters. Arrows indicate the medium flow.