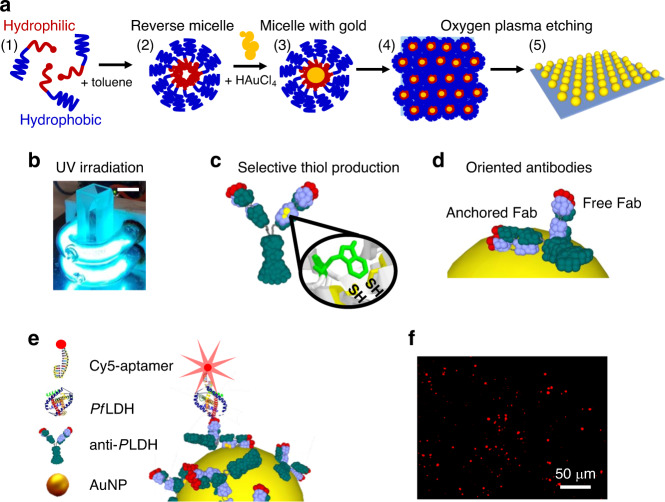

Fig. 1. Operating principle of the device.

a Fabrication process of AuNP array by BCMN: (1) dispersion of diblock copolymers with amphiphilic character in toluene solution; (2) formation of reverse micelles with hydrophilic core and outer hydrophobic shell; (3) loading of the gold precursor inside the micelles; (4) sticking of the PS-AuNPs on the substrate through hydrophobic interaction; (5) immobilization of the AuNPs on the substrate after copolymer etching. b Low pressure mercury U-shaped UV lamps used to carry out the biofunctionalization of AuNPs with antibodies through PIT. A standard 10 mm cuvette can be easily housed inside the internal volume (the length of the scale bar in the top-right corner is 1 cm). Given the proximity of the cuvette to the lamps and the wrapping geometry, we estimated that the solution was exposed to an UV-irradiation of 0.3 W/cm2. c UV irradiation of the Abs leads to the production of four thiol groups (two of them are not visible in the figure). d The position of the thiols, opposite with respect to the plane containing the antibody Fabs, allows to immobilize the Abs with one of their binding sites exposed to the surrounding environment. e Sketch of the Ab-PfLDH-aptamer sandwich scheme used throughout the experiments. The adoption of Abs as bottom receptor layer and aptamers as top layer allows the fluorophore to be placed at a distance of approximately 10 nm from the surface. f Example of fluorescence picture acquired at 1 pM (35 pg/mL) PfLDH concentration. The red spots arise from the fluorescence emitted by a single Cy5 molecule.