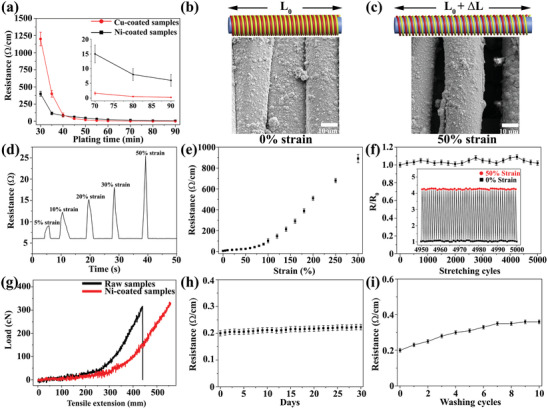

Figure 3.

a) The conductivity results of Ni (black) or Cu (red)‐coated yarns at different ELD durations (n = 5). SEM images and the scheme illustrations of nickel‐coated yarns at b) 0% strain and c) 50% strain. d) The resistance changes of conductive yarns when stretching and releasing at different strains. e) The resistance changes of as‐made nickel‐based yarns when continuously stretching to 300% elongation (n = 5). f) Resistance stability of sensor materials under repetitive stretching (50% strain) and relaxing (0% strain) cycles (the change in resistance is defined as: R/R 0) (n = 5). g) The tensile test of raw elastic yarns and Ni‐coated stretchable yarns (the original sample length is 45 mm). The durability test of Cu‐coated samples including h) air stability (n = 5) and i) washing fastness (n = 5).