Table 2.

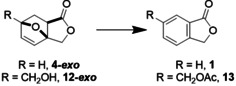

Optimization of the aromatisation reaction to give phthalides. All reactions with 4‐exo, unless stated otherwise.

|

Entry |

Solvent |

Catalyst |

Loading [equiv] |

Ac2O |

T [°C][a] |

Yield [%][b] |

|---|---|---|---|---|---|---|

|

1 |

Neat |

MsOH |

13 |

20 vol % |

20 |

75 |

|

2 |

|

|

0.5 |

4 equiv |

20/80 |

97[c] |

|

3 |

|

|

0.5 |

4 equiv |

80 |

98 |

|

4 |

|

|

0.1 |

4 equiv |

80 |

95 |

|

5 |

|

|

0.02 |

4 equiv |

80 |

94 |

|

6 |

|

|

0.01 |

4 equiv |

80 |

39 |

|

7 |

|

TfOH |

0.01 |

4 equiv |

80 |

95 |

|

8 |

|

H2SO4 |

0.01 |

4 equiv |

80 |

80 |

|

9 |

|

Amberlyst 15 |

0.1 |

4 equiv |

80 |

82 |

|

10 |

EtOAc |

|

0.1 |

4 equiv |

80 |

78 |

|

11 |

|

|

0.1 |

2 equiv |

80 |

89 (79)[d] |

|

12[e] |

Neat |

MsOH |

0.5 |

8 equiv |

80 |

60[f] |

|

13 |

Neat |

MsOH |

13 |

0 |

20 |

66 |

|

14 |

d8‐Toluene |

MsOH |

0.1 |

0 |

80 |

66 |

|

15 |

|

Hf(OTf)4 |

0.1 |

0 |

80 |

60 |

|

16 |

|

TfOH |

0.1 |

0 |

80 |

63 |

|

17 |

|

TfOH |

0.01 |

0 |

80 |

63 |

|

18 |

|

TfOH[g] |

0.01 |

0 |

80 |

58 |

|

19 |

CDCl3 |

TfOH |

0.1 |

0 |

80 |

79 |

|

20 |

CH3COOH |

TfOH |

0.1 |

0 |

80 |

56 |

[a] Acid/Ac2O added at 0 °C and then warmed to 20 or 80 °C as specified. [b] Determined by quantitative 1H NMR. [c] Reaction mixture heated to 80 °C for 1 h after 22 h at 20 °C. [d] Yield using recycled Amberlyst catalyst. [e] Using 12‐exo as the substrate. [f] Isolated yield. [g] Silica‐supported TfOH acid. [38]