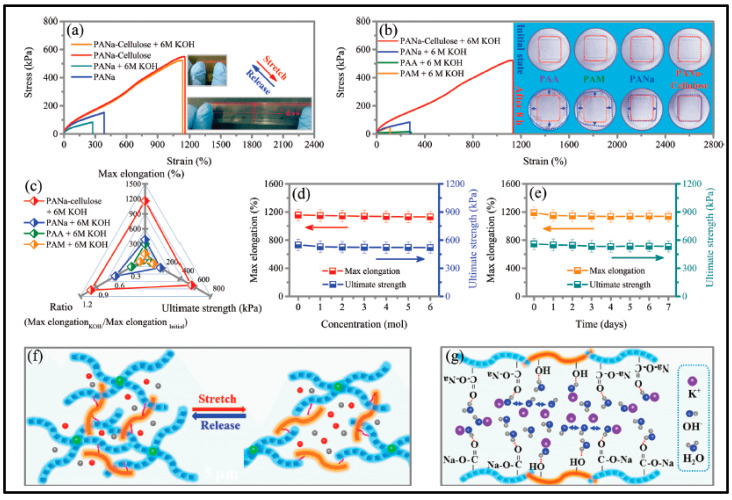

Figure 14.

(a) Tensile stress versus strain curves of the as-synthesized PANa and PANa-cellulose hydrogel electrolyte with and without 300% 6 M KOH + 0.2 M Zn(CH3COO)2 intake. The insets are optical photos of the relaxed and elongated states of the 300% 6 M KOH + 0.2 M Zn(CH3COO)2 solution incorporated PANa-cellulose hydrogel electrolyte showing excellent stretchability. (b) Comparison of tensile properties of PAA, PAM, PANa and PANa-cellulose hydrogel under alkaline condition. The inset is the photos of PAA, PAM, PANa and PANa-cellulose hydrogel at initial state and containing 300% 6 M KOH solution for 8 h. The red and blue rectangle represent the shape of hydrogel before and after infiltrating alkaline solution. (c) Comparison of alkaline-tolerant capability of different hydrogel electrolyte. (d) Ultimate strength and maximum elongation of PANa-cellulose hydrogel electrolyte containing KOH solution with different concentrations. (e) Ultimate strength and maximum elongation of PANa-cellulose hydrogel electrolyte containing 300% 6 M KOH solution after different alkaline corrosion times. (f) Schematic illustration for origin of ultra-stretchability. (g) Schematic diagram reflecting structure of PANa-cellulose hydrogel electrolyte entrapped KOH and water via the interactions of hydrogen bonds.Reproduced with permission from [273]. Copyright 2019 Wiley.