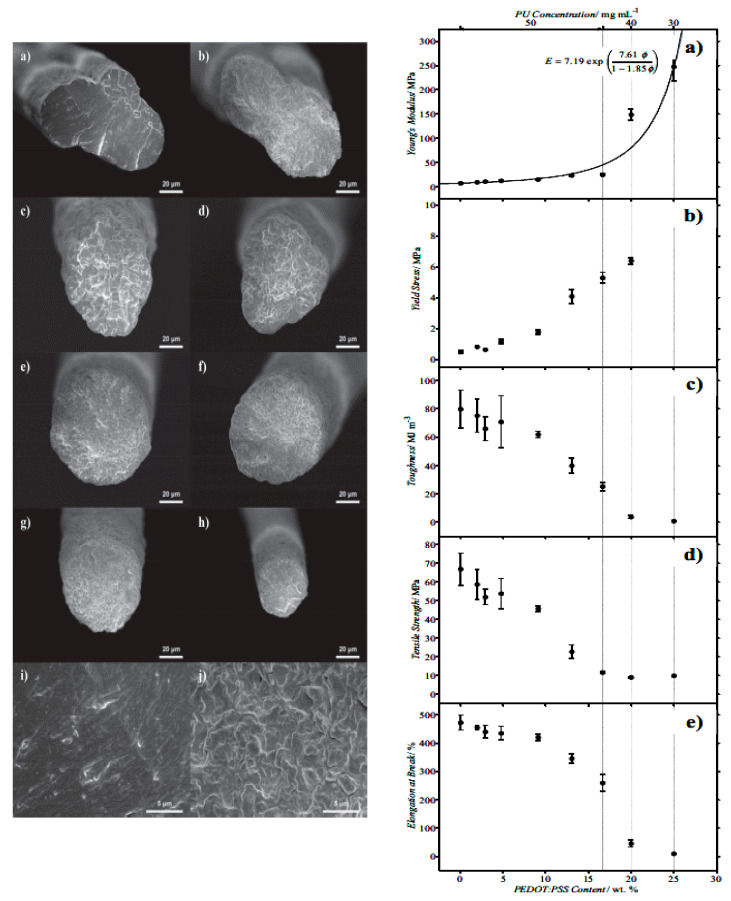

Figure 17.

(Left) SEM micrographs of fibers produced from spinning formulations in DMSO into a coagulation bath of isopropanol/water (80/20 v/v): (a) pure PU fiber, b–h) PU/PEDOT:PSS fibers with PEDOT:PSS loadings of (b) 2.9 wt%, (c) 4.8 wt.%, (d) 9.1 wt.%, (e) 13.0 wt.%, (f) 16.7 wt.%, (g) 20.0 wt.%, (h) 25.0 wt.%, (i) higher magnification of (a), and (j) higher magnification of (e). (Right) Mechanical properties of PU/PEDOT:PSS fibers at different PEDOT:PSS content: (a) Young’s modulus, (b) yield stress, (c) toughness, (d) tensile strength, and (e) elongation at break [69].