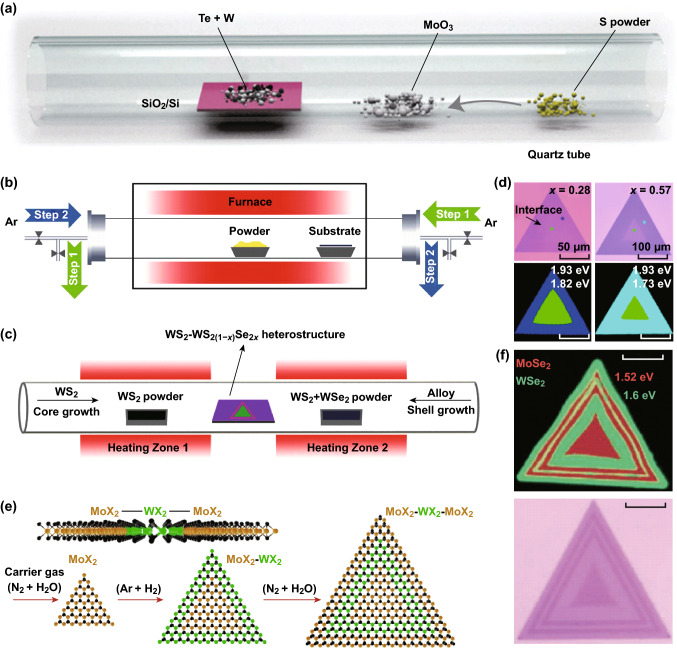

Fig. 2.

Chemical vapor deposit (CVD) growth. a The diagram of the synthesis of MoS2/WS2 heterostructures through one-step CVD method. S powder is placed at the upstream, and a wafer with mixed powder of W and Te is put downstream. Reprinted with permission from Ref. [27]. b Multi-step CVD growth of realized through direction-switchable carrier flow and cooling process. Reprinted with permission from Ref. [32]. c the modulable growth of WS2 − WS2(1−x)Se2x (0 < x ≤ 1) monolayer lateral heterostructures using dual heating quartz tube and d the optical picture and PL intensity mappings of heterostructures with different x. Reprinted with permission from Ref. [30]. e The principle of one-pot synthesis strategy and f the optical picture and PL intensity mappings of the hetero-superlattice indicating the sharp interlines. Reprinted with permission from Ref. [31]