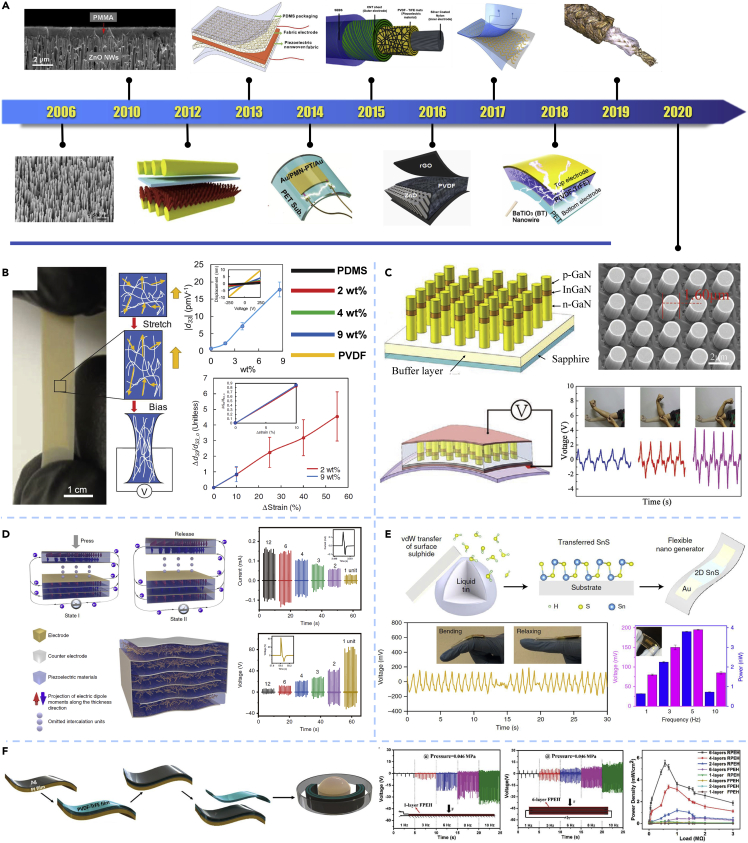

Figure 3.

Recent progress of wearable PENGs

(A) A road map of representative wearable PENGs in the past decade. Reprinted from ref (Huang et al., 2017; Hwang et al., 2014; Jeong et al., 2018; Kim et al., 2012; Mokhtari et al., 2019; Shin et al., 2016; Sim et al., 2015; Zeng et al., 2013; Zhu et al., 2012) with permission, Copyright©2009 Elsevier Ltd, Copyright©2012 American Chemical Society, Copyright©2012 The Royal Society of Chemistry, Copyright©2013 The Royal Society of Chemistry, Copyright©2014 WILEY-VCH Verlag GmbH & Co, Copyright©2015 WILEY-VCH Verlag GmbH & Co, Copyright©2016 Elsevier Ltd, Copyright©2017 Elsevier Ltd, Copyright©2018 WILEY-VCH Verlag GmbH & Co, Copyright©2019 The Royal Society of Chemistry.

(B) A stretchable PENG based on BNNT/PDMS with tunable piezoelectricity and enhanced mechanical strength and thermal conductivity. Reprinted from ref (Snapp et al., 2020) with permission, Copyright©2020 WILEY-VCH Verlag GmbH & Co.

(C) A wearable strain sensor based on GaN pn junction microwire arrays with high sensitivity and robustness. Reprinted from ref (Cheng et al., 2020) with permission, Copyright©2020 WILEY-VCH Verlag GmbH & Co.

(D) A PENG with novel three-dimensional intercalation electrode with improved current density. Reprinted from ref (Gu et al., 2020) with permission, Copyright©2020 The Authors.

(E) A flexible PENG based on monolayer 2D material SnS. Reprinted from ref (Khan et al., 2020) with permission, Copyright©2020 The Authors.

(F) A bull-structured PENG with multilayer P(VDF-TrFE). Reprinted from ref (Yuan et al., 2020) Copyright©2020 The Royal Society of Chemistry.