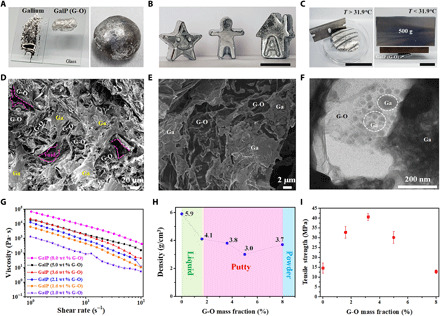

Fig. 1. Synthesis and characterization of a metallic putty made from liquid gallium with a graphene oxide filler.

(A) Left photo shows liquid gallium and GalP (G-O) (3.6 wt % G-O) on glass slides; right photo shows a GalP (G-O) (8.0 wt % G-O) ball with some brown regions on its surface due to the high G-O loading—this GalP (G-O) is easy to crack. (B) GalP (G-O) is highly processable and versatile; it can be readily reshaped to a five-pointed star, a figurine, and a house. Scale bar, 2 cm. (C) Photos showing that GalP (G-O) can be either soft or stiff depending on the temperature: A 5-g piece of soft GalP (G-O) can be sliced easily when T > 31.9°C (left), and the slice can support a 500-g steel block when T < 31.9°C (right). Scale bars, 2 cm. (D) SEM image of GalP (G-O); pink dotted lines indicate some pores generated by the stacking of the G-O sheets. (E) Magnified SEM image and (F) TEM image showing the combination of a G-O sheet with gallium. (G) Viscosity of GalP (G-O) (with different G-O mass loading) under different shear rates. (H) Density of GalP (G-O) as a function of the G-O mass fraction. (I) Tensile strength of GalP (G-O) with different G-O mass fractions. Photos in (A) and (B) were taken at 26°C, and Ga in (A) is liquid due to supercooling. Photo credits: Chunhui Wang, Center for Multidimensional Carbon Materials, Institute for Basic Science.