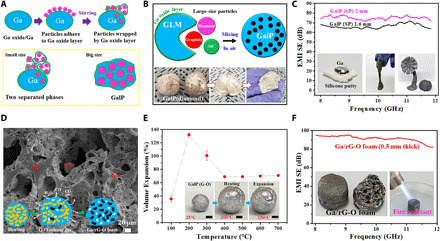

Fig. 2. Fabrication of various nonmetallic/GLM composites and a porous Ga/rG-O foam.

(A) Illustration of the formation mechanism of GalP; the particle size and Ga oxide layer are two key factors in the formation of GalP. (B) Illustration showing the fabrication of GLM composites by mixing graphite flakes, diamond, or SiC particles with GLM; as long as the particle size is large enough, it is able to be incorporated with GLM. (C) EMI SE of a GalP (SP) composite with thicknesses of 1.6 and 2.0 mm. Inset: Photos showing that GalP (SP) is stretchable. (D) SEM image of a porous Ga/rG-O foam. Inset: Illustration showing the volume expansion of GalP (G-O); the blue background represents the Ga matrix, the yellow sheets represent G-O, the black sheets represent rG-O, and the white dots are the pores formed. (E) Volume expansion of GalP (G-O) with different G-O mass loadings as a function of temperature. Inset: Optical photos showing the volume expansion of a GalP (G-O) (3.6 wt % G-O) ball upon heating. Scale bars, 2.0 cm. (F) EMI SE of porous Ga/rG-O foam with a thickness of 0.5 mm. Inset: Left photo shows the exterior and interior of a Ga/rG-O foam; right photo shows that the Ga/rG-O foam is heat resistant, as it remains stable under a blowtorch. Photos in (B) and (C) were taken at 26°C. GalP (D) and GalP (SP) are soft due to being handheld. Photo credits: Chunhui Wang, Center for Multidimensional Carbon Materials, Institute for Basic Science.