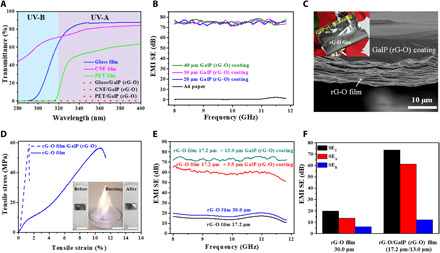

Fig. 3. GalP on various substrates as a UV or electromagnetic shielding coating.

(A) UV-vis spectra of glass/GalP (rG-O), CNF/GalP (rG-O), and PET/GalP (rG-O) film. The transparent glass, CNF, and PET films exhibit complete shielding of UV rays in both the UV-B and UV-A regions, after coating with 1-μm-thick GalP (rG-O) coating. (B) EMI SE of GalP (rG-O) of different thicknesses coated on a commercial A4 paper. (C) SEM image of the cross section of an rG-O/GalP (rG-O) film. Inset: Photo showing the rG-O film with a GalP (rG-O) coating; the composite film is highly flexible and can be rolled up. (D) Tensile strain-stress curves of a rG-O and rG-O/GalP (rG-O) film. Inset: The GalP (rG-O) coating is heat-resistant and has a strong adhesion to the rG-O film; a piece of rG-O/GalP (rG-O) composite film remains unchanged after being burned in an alcohol solution in air. (E) EMI SE of rG-O films at a thickness of 17.2 and 30.0 μm, and 17.2-μm-thick rG-O films with 3.5- and 13.0-μm-thick GalP (rG-O) coatings. (F) Total EMI SE (EMI SET) and its absorption (SEA) and reflection (SER) components in ~30.0-μm-thick rG-O film and rG-O/GalP (rG-O) film at 8.0 GHz.