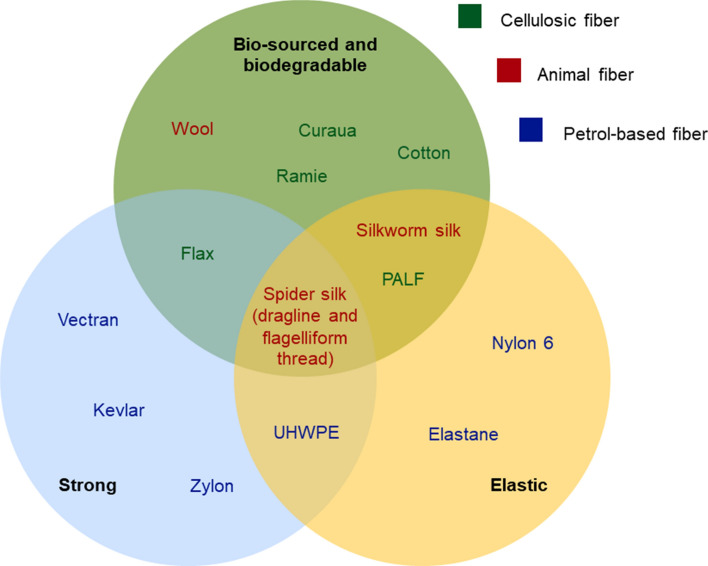

Fig. 6.

Position of diverse fibers. Are considered strong materials with an average ultimate tensile strength over 0.95 GPa, elastic materials with a strain at break over 7%. These thresholds were based on the median value of all our fibers’ average numbers for each property. Of all fibers compared for their mechanical characteristics in this review, only spider silk (dragline and flagelliform threads) embodies a crossover between strength (values obtained for ultimate tensile strength), elasticity (values obtained for strain at break) and organic nature. The advantage of a bio-sourced fiber in comparison with petrol-based material, is that not only its synthesis is realized in water and without high energy input, but also its breakdown after use can be achieved in nature without toxic consequences for ecosystems. References for Kevlar® (n = 2/2) (Quintanilla), Zylon® (n = 3/3) (Seely et al. 2004; Kumar et al. 2002; Zhang et al. 2018; Hao et al. 2019), Vectran® (n = 1/1) (Tanaka and Moritaka; Clements 1998; Ward 2012), UHWPE (n = 1/1) (Ogawa et al.; Dayyoub et al. 2019), elastane (n = 1/1) (Senthilkumar et al. 2011), Nylon 6 (n = 4/4) (Rangari et al. 2008; Bhattacharyya et al. 2009), spider’s silk (n = 4/4) (Heim et al. 2009; Teule et al. 2012), silkworm’s silk (n = 13/18) (various sources referenced in) (Zhao et al. 2006), Curaua (n = 3/2) (Yan et al. 2016; Monteiro et al. 2010), PALF (n = 2/2) (Yan et al. 2016), Ramie (n = 1/1) (Kumar et al. 2020), cotton (n = 2/2) (Yan et al. 2016), Flax (n = 2/2) (Yan et al. 2016; Zhu et al. 2013) and wool (n = 3/4) (Smith et al. 2014; Yükseloğlu et al. 2015). n: number of gathered values per mechanical property (ultimate tensile strength/strain at break)