Abstract

Background and objectives

Pharmaceutical sterile wastes are not only environmental hazard but an economical loss. There are many strategies employed in various parts of the world for minimizing the parenteral admixture returns in hospitals, however, they are not practiced in Saudi Arabia. Therefore, this study was done to assess the impact of a) intravenous (IV) pharmacy round and b) twice daily batching, as reduction strategies on the number of IV admixture returns and the associated cost of medication wastage.

Method

This study was conducted at the central IV room of the in-patient pharmacy unit at King Fahad Medical City, Riyadh, Saudi Arabia for general intensive care unit (ICU) IV returns. Phase 1 of the study was intended to measure the baseline parameters, while the Phase 2 and 3 were measured with the application of IV pharmacy round plan, and twice-daily batching strategies, respectively. Comparison of IV returns were done in each of the phases and economical loss was calculated.

Results

Out of number of IV admixtures prepared and supplied to ICU during a month, 4.85% of the items were deemed wasted during baseline phase with as estimated cost of IV wasted items to be 2,128.02 USD. In the IV pharmacy round and twice-daily batching strategies, the percentage of the wasted items decreased to 4.27% and 3.73%, respectively. Moreover, there is 13.84% and 42. 48% reduction in the estimated cost in the wasted items in, pharmacy round and twice-daily batching strategies, respectively, compared to baseline phase.

Conclusion

Implementation of interventions caused reduction in total recycled, wasted items and the associated cost of medication wastage of sterile pharmaceutical preparations. Twice daily batching strategy has better effect in decreasing the IV returns and its associated cost.

Keywords: Batching strategy, ICU, IV waste, IV returns, IV medications, Pharmacy round, Saudi Arabia

1. Introduction

Compounding intravenous (IV) medication is one of the major operational tasks of the inpatient pharmacy department and a standard operating procedure (SOP) at hospitals acquiring national and international accreditation. The wastage of IV admixture is a well-documented source of financial loss to the hospital pharmacy budget (Daughton, 2003). Internationally, the observed rate of IV wastage is 6% from total IV preparation in the majority of hospitals (Newhouse et al., 1988). A study reported IV admixture wastage totaled USD 72000 (8.8%) of the annual budget (Hoolihan and Erickson, 1987). Another study reported an estimated loss of USD 26077 annually (6.2% intravenous admixture preparations) due to IV waste in their centralized pharmacy (Salberg et al., 1984). A report from Uchida et al (1994) quoted the cost of IV medication waste in the retrospective study for a 12-month period by USD 90000. In Saudi Arabia, King Khalid University Hospital reported that their monthly IV admixture wastage was USD 7700 which correlated to 4.4% of the total IV budget (Al-Dhawailie, 2011). While, in King Abdulaziz Medical City, a tertiary care hospital in Saudi Arabia, recently estimated that the total cost of all IV medications returns reached USD26805.80, which accounts for almost 13.7% of the total pharmacy’s budget (AlSamanhodi et al., 2017).

As 80% of compounded sterile product (CSP) get cancelled within 7 days of its initiation and usually returned to the pharmacy (Dobson et al., 2015), it is imperative to implement strategies that can work on streamlining the flow of medication from pharmacy to inpatient units. The major documented reasons for high percentage of IV admixture returns are medication discontinuation, switching from IV to oral route, dose changed, providing extra dose, patient discharge, patient transfer or patient death (Abbasi and Gay, 2017, AlSamanhodi et al., 2017). Several strategies are developed and successfully implemented during the past three decades to reduce IV medication returns. One of these strategies is preparing daily IV admixtures in multiple batches distributing the workload into standard hours such as every 12 h, 8 h or 6 h (Chiu and Chien-Hsiang, 2010, Toerper et al., 2014, Dobson et al., 2015). In a previous study conducted in children’s hospital confirmed that switching from one daily batch to a three times per day batching strategy resulted in 31.3% reduction in medication waste with an estimated cost saving USD183380 annually (Toerper et al., 2014). Another study suggested strategy of implementing an IV pharmacy round, in which the pharmacist engages in various activities to reduce the IV medication returns (Lin et al., 2018).

Till date, no published literature is available regarding impact of batching or pharmacy rounding strategies on the number of IV admixture returns in Saudi Arabia. In King Fahad Medical City (KFMC), preliminary data found that the average number of IV preparations in inpatient pharmacy of the Main Hospital, excluding chemotherapy using single daily batch, is approximately 50,000 monthly (1600 IV preparations daily). Therefore, the objective of this study was to assess the effects of implementing twice daily batching and IV pharmacy rounding as reduction strategies on the number of IV admixture returns and the associated cost of medication wastage.

2. Materials and methods

2.1. Study design and setting

This study was conducted in the IV admixture room of the central in-patient pharmacy of the main hospital at King Fahad Medical City (KFMC), a tertiary care hospital in Riyadh, Saudi Arabia, with 500 adult beds, of which, 36 are located in the general intensive care unit (ICU). The data collected from general ICU during September to December 2019. All wasted and recycled items (IV medications) returned to the IV admixture preparation room from general adult ICU were included in the study, whereas IV returns from neuroscience ICU, CCU, and pediatric ICU, as well as oncology IV preparations, were excluded from this study.

2.2. Data collection

Data was gathered and entered on Excel sheet during the study period using the following variables: number of daily IV preparations items, date of preparation, the name of recycled medications, name of wasted medications, strength of the drug, total vials quantity, reason of waste, type and the volume of diluents, and total wasted item cost. Data collection was done on a daily basis by the pharmacist and assistant pharmacist and submitted to the principal investigator. All IV returns were placed in an allocated container in the refrigerator to be sorted by the assistant pharmacist into recycled and wasted items based on the stability of the IV preparation items. Recycled preparation items defined as an admixture medication that can be re-used before the expiry date. The wasted preparation item is defined as expired admixture medication that cannot be administered to the patient.

2.3. Study interventions

There were three phases of this study. In the first phase (month 1), before implementing the study intervention, all data mentioned above were collected as baseline data using the KFMC routine practice (once daily batch) in preparing the IV medications to assess the number of IV returns and to calculate the cost of IV wasted medications. A washout period of one week was given at the end of baseline line phase to allow sufficient clearance so that all IV admixtures produced under the baseline phase (24-h batching frequency) to be consumed/ or returned to the IV unit before the start of the second phase.

The second phase (month 2), IV pharmacy round strategy was implemented for all items from general ICU to measure its effect on IV returns in comparison to baseline (phase 1). During this phase, the pharmacist performs three initiatives on daily basis as a part of his/her tasks. (i) The pharmacist resolves any discrepancies between electronic medication record and manual physician order by taking the list of patients on IV medications and compares the electronic sheet to the medication administration record (manual medical record), removes unused IV preparations in the medication refrigerator allocated in the ICU ward by checking the medications refrigerator and medications room for any extra dose and verifying adequate doses until next delivery, (ii) coordinates IV preparation for scheduled discharge and transfer patients by holding the IV preparation items for all patients planned for discharge or transfer (discharge patients list sent through KFMC mail) unless further notification from primary nurse, and (iii) separates expensive IV medication from ongoing medications to be prepared 2 h prior administration in order to avoid abrupt drug discontinuation or modification resulting in medication waste. All three initiatives of phase 2 were implemented for the first time in KFMC until this study was done.

At the end of washout period of one week after phase two, we studied the impact of utilizing twice daily batching strategy (Phase three) instead of once daily batch for IV medication preparation in general ICU and evaluated its effect in IV wastage and returns. Time of printing medication labels (prints out labels for all of the patients doses needed to be administered over a specific period), the timing of IV admixture preparation, and medication delivery to the units for the first and the second batch are listed in compounded sterile products batch frequency schedule (Table 1). The first batch started in the morning with printing labels of scheduled medication dose at 06:00, then preparation of sterile IV medications at 07:30, finally to be delivered via nurse at 14:00 to cover the patient scheduled dose from 16:00 to 03:59. On the other hand, the printing time at 13:00, preparation time at 14:00, delivery time at 17:30, and covering administration time from 04:00 to 15:59 is for the second batch; since the study conducted in one unit, re-staffing and changing staff arrangement was feasible. One modification in the staff schedule was done for the technician to start the shift from 10:30 instead of 07:30 (late shift) for assisting in preparing second batch items. Time selection for the second batch to prepare IV admixture medications was specified at 14:00 at which time most of the physicians finished the daily round and consequently fewer order modifications.

Table 1.

Batching schedule-Phase 3.

| Batch No | Printing time | Preparation time | Delivery time | Administration time |

|---|---|---|---|---|

| 1 | 06:00–07:00 | 07:30–12:30 | 14:00 | 16:00–3:59 |

| 2 | 13:00–14:00 | 14:00–17:00 | 17:30 | 04:00–15:59 |

Each item of IV medications returns was calculated by unit price cited by the pharmaceutical planning officer at KFMC. Only direct cost of medications items were calculated.

2.4. Ethical approval

The institutional review board of King Fahd Medical City, Riyadh, Saudi Arabia provided ethical approval to carry out this research during their meeting in July 2019 with a validity of one year to complete this study.

2.5. Data management and analysis

Data obtained from the study were categorical and expressed as frequency and percentages. Statistical Package for the Social Sciences (SPSS 22.0) was used for further analysis.

3. Results

During the first phase (baseline), out of 3750 IV medications items prepared for general ICU patient (36 beds), 408 (10.88%) medications were returned to the pharmacy including 226 (55.4%) recycled items and 182 (44.6%) wasted items (Table 2). The total cost of IV wasted items from ICU in one-month baseline is 2128.02 USD (7974.87 SAR) representing 4.85% of the items wasted monthly prior to the intervention of intended strategy.

Table 2.

Comparison of the IV medications returns and cost before and after implementation of the study interventions.

| Strategy | Total number of items returned to pharmacy | Recycled items, n (%) | Wasted items, n (%) | Cost of wasted items (USD) |

|---|---|---|---|---|

| Baseline | 408 | 226 (55.4) | 182 (44.6) | 2,218.02 |

| IV Pharmacy round | 360 | 201 (55.8) | 159 (44.2) | 1,911.02 |

| Twice daily batching | 244 | 141 (57.8) | 103 (42.2) | 1,276.05 |

Subsequently, a washout period of one week was given to allow sufficient clearance so that all IV admixtures produced under the baseline phase (24-h batching frequency) to be consumed/ or returned to the IV unit before the start of the second phase.

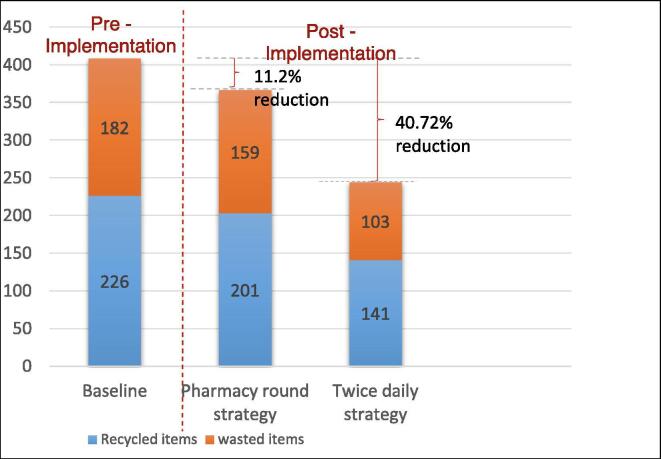

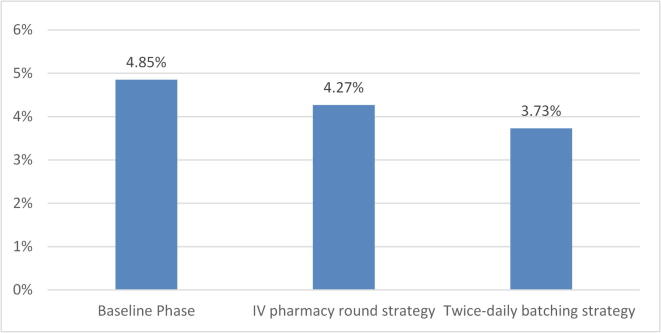

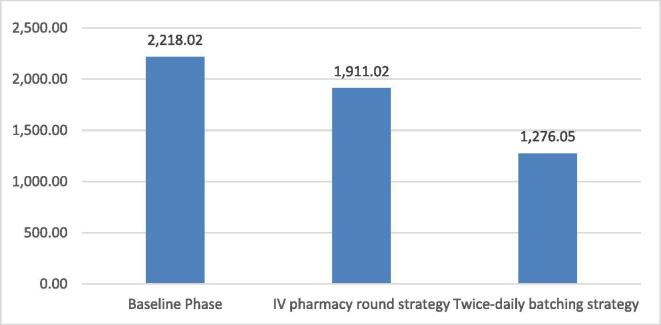

After adapting IV pharmacy round strategy, out of the 3720 items prepared and supplied during this month, only 360 items were returned exhibiting a drop in the percentage of IV return from 10.88% in the phase 1 compared to 9.67% in this phase, so a total decrease in IV returns of 11.2% observed in this phase compared to baseline phase (Fig. 1). Out of these returned items, 201 (55.8%) and 159 (44.2%) were recyclable and wasted items, respectively. The total cost of IV wasted items during the IV pharmacy round estimated to be 1911.02 USD which is accounted by 13.84% cost reduction from baseline. Therefore, the percentage reduction of the wasted items in the pharmacy round strategy decreased to 4.27% from 4.85% of the baseline phase (Fig. 2).

Fig. 1.

Change in return before and after implementation of the study interventions in general ICU.

Fig. 2.

Percentage of wasted items.

After the end of one week washout period, twice-daily batching strategy was implemented. There were 3780 IV admixtures prepared and supplied by pharmacy to ICU units during this month, 244 (6.45%) of them were returned. This exhibit a drop in percentage of IV admixtures returns during this phase from 10.88% in baseline phase to 6.45% with an overall decline of 40.72% (Fig. 1). Of 244 items, 141 items (57.8%) were recycled while 103 items were wasted (42.2%) (Table 2). The estimated cost (1276 USD) reduction percent of IV wasted items is 42.48% as compared to the cost of the wasted items in baseline phase (Fig. 3). The percentage reduction in the wasted items in twice daily batching strategy dropped to 3.73% compared to 4.85% of the baseline phase.

Fig. 3.

Cost of wasted items (USD).

The estimated annual cost reduction from general ICU during pharmacy round strategy is 3684 USD, while for batching strategy is 11303 USD if similar pattern of supplies and returns are maintained throughout the year.

4. Discussion

Wastage of sterile pharmaceutical compound is one among the many reasons for escalation in hospital pharmacy budget. This study experimented some strategies that can minimize such wastages.

Although the IV medications wastage (4.85%) prior to the intervention of our strategies were below the acceptable international rate of IV wastage which is 6% of total IV preparation in the majority of hospitals (Salberg et al., 1984), with the implementation of our strategies, IV pharmacy round and twice-daily batching, the percentage of wastage of IV admixtures could be further decreased to 4.27% and 3.73%, respectively. Diehl et al. (1992) developed IV waste reduction program which involved totally ten measures. Two measures were adapted in our study during pharmacy round plan include removing unused solutions from nursing units and verifying telephone orders whereas fives measures were already established before conducting the study which included recycling solutions, using a standardized administration schedule, using automatic stop orders, using commercially prepared products, and preparing labile products immediately before administration. In this study, some measures of pharmacy round strategy were concomitantly studied with the batching plan but not evaluated separately. Thus, absolute cost saving from each measure cannot be predicted. Moreover, there was no pre and post comparison percentage of IV waste, so it is difficult to demonstrate the real impact of cost saving for these strategies. On the other hand, our results showed twice daily batching strategy have substantially reduced the IV returns and its associated waste cost by 42.28%. Moreover, our results illustrated that the twice-daily batching has greater effect in decreasing the IV returns and cost than IV pharmacy round. Similarly, a study conducted by Chiu and Chien-Hsiang (2010) showed that adapting twice daily batching strategy can decrease their monthly medication waste from USD 9909 in once daily batching compared to USD 4828 for twice daily batching which represents 48.72% IV waste reduction. Increasing daily batches helps in reducing IV waste and missing doses and ultimately provide substantial advantages in term of cost saving and improved patient care (Gorrel, 2012, Toerper et al., 2014).

In a comparison of different batching frequencies which simulated computer modeling technique, three-time daily batching schedules have a higher reduction rate of wasted medications and lower wasted cost compared to twice daily and once daily batching strategies (Chiu and Chien-Hsiang, 2010). It was reported that three daily batching schedule decreased monthly wasted dose by 80% (79.70–81.06%) and monthly waste cost reached 3,548$ to 3,804$ compared to twice daily batching strategy lowered wasted medications by 71–76% monthly with estimated cost 4,197 to 5,511$ (Chiu and Chien-Hsiang, 2010). Moreover, previous studies revealed that adaptation of the batching process lowers the staff workload (labor requirements) and considers cost saving process (Abbasi and Gay, 2017, Jenkins et al., 2010). A 24-hour dose coverage time frame during once daily batching creates larger opportunity for uncontrollable factors of medications waste such as discontinued doses and patients discharge or death. In our study, twice-daily batching schedule succeeded in lowering the IV returns and waste by overcoming some of the reasons of medications waste such as medication discontinuation, switching from IV to oral route, dose changed and patient death. On the other hand, pharmacy round plan lowered the IV returns and cost from patient discharge, patient transfer and discrepancy in the required dose.

Time selection for the second batch played an important role in controlling the medications waste. According to a previous study, the best option of twice daily schedule is preparing ongoing medications at 04:00 and 12:00 (Chiu and Chien-Hsiang, 2010). The timing of the second batch is determined by knowing the period in which order modification and discontinuation are high. The proportion of order modification and medications discontinuations is surging at 9 to 11 AM after daily morning rounds (Toerper et al., 2014). Thus, the second batch of our study is preceded at 14:00 after physicians’ rounds end where the medications discontinuation and modification are frequent.

Minimizing IV medications waste can be accomplished by implementing different strategies (Hintzen et al., 2009, L’Hommedieu and Kappeler, 2010, Paoletti and Casey, 2000). Purchasing premixed IV solutions approach has been shown to minimize IV waste to 2.35% and also able to absorb an additional 37% increase in workload (Newhouse et al., 1988). Paoletti and Casey (2000) adapted centralization and standardization of an IV admixture program. It consists of 8 strategies includes constructing a class 10,000 clean room to provide a cleaner environment resulting in IV medications stability prolongation, standardizing the concentration of IV solution, and supporting pharmacy staff to contribute in IV round which results in minimization IV waste from 5% to 2% over 5 months. Although renovation of clean room costed 97,500 USD, total cost savings from this program was 191,640 per year. However, such program cannot be implemented in our hospital because of difficulty in standardizing IV medications since dosing is based on the weight and age.

These current results provide general insights that might help pharmacy leaders to adapt new strategies for IV preparation to decrease the number of IV admixture returns and the associated cost of medication wastage.

Since the frequency of medications cancellation or modification is varied from critical and non-critical units (medical, oncology, cardiology, neurology, nephrology ward), the answer of what is the optimal number of batches for each unit question is not readily available and need to be studied in order to determine the appropriate frequency of batching strategy for each unit in the hospital.

There are some limitations in this study as it was conducted in a single adult ICU unit which may not provide similar IV waste reduction percentage in other units. Staff resistance to the changes in the workflow may preclude extrapolating batching strategies. Other limitations are short duration and not calculating the non-direct costs of IV medications such as staff workload and disposable material used during IV preparation. Delivery of compounded sterile products to ICU unit is one drawback of batching strategy.

5. Conclusions

Implementation of IV pharmacy round and twice batching plans lowered the total IV returns and the cost of associated wasted medications. Twice daily batching strategy had better effect in reducing the IV returns and its associated cost, thus, it is more economical.

Role of funding source

The authors would like to thank the Research Center at King Fahd Medical City, Riyadh, for their financial support provided for the manuscript.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

The author extends warm thanks to all pharmacist and nursing staff for helping us to accomplish the research procedures. The authors are thankful to AlMaarefa University, Riyadh for providing support to conduct this research.

Footnotes

Peer review under responsibility of King Saud University.

References

- Abbasi G., Gay E. Impact of sterile compounding batch frequency on pharmaceutical waste. Hospital Pharm. 2017;52(1):60–64. doi: 10.1310/hpj5201-60. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Al-Dhawailie Abdulatif A. Control of intravenous medication wastage at a teaching hospital in Saudi Arabia. Saudi Med. J. 2011;32(1):62–65. [PubMed] [Google Scholar]

- AlSamanhodi H., Almeshary M., Amoh K., Aldekhael S., Alkatheri A., Alharbi S. Evaluation of the causes and cost impact of returned intravenous medications at a tertiary care hospital in Riyadh, Saudi Arabia. Trop J. Pharm. Res. 2017;16(1):231–237. [Google Scholar]

- Chiu, Chien-Hsiang . University of Cincinnati; 2010. The effects of intravenous admixture batching schedules on waste-a computer simulation approach. Diss. [Google Scholar]

- Daughton C.G. Cradle-to-cradle stewardship of drugs for minimizing their environmental disposition while promoting human health. I. Rationale for and avenues toward a green pharmacy. Environ. Health Perspect. 2003;111:757–774. doi: 10.1289/ehp.5947. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Diehl L.D., Goo E.D., Sumiye L., Ferrell R. Reducing waste of intravenous solutions. Am. J. Hosp. Pharm. 1992;49(1):106–108. [PubMed] [Google Scholar]

- Dobson G., Tilson D., Tilson V. Optimizing the timing and number of batches for compounded sterile products in an in-hospital pharmacy. Decis. Support Syst. 2015;1(76):53–62. [Google Scholar]

- Gorrel J.J. Reduce waste by increasing daily IV batches. Pharm. Purchasing Products. 2012;9(6):2. [Google Scholar]

- Hintzen B.L., Knoer S.J., Van Dyke C.J., Milavitz B.S. Effect of lean process improvement techniques on a university hospital inpatient pharmacy. Am. J. Health-Syst. Pharm. 2009;66(22):2042–2047. doi: 10.2146/ajhp080540. [DOI] [PubMed] [Google Scholar]

- Hoolihan Roar J., Erickson Bruce A. Strategies for reducing IV drug waste and coping with increased workload. Hospital Pharm. 1987;22(9):871–876. [PubMed] [Google Scholar]

- Jenkins A., Rowe E., Granko R., Pfeiffenberger T., Daniels R. Effects of a new sterile product preparation and delivery process on operational efficiency and cost. Am. J. Health-Syst. Pharm. 2010;67(19):1645–1649. doi: 10.2146/ajhp090470. [DOI] [PubMed] [Google Scholar]

- L’Hommedieu T., Kappeler K. Lean methodology in iv medication processes in a children’s hospital. Am. J. Health-Syst. Pharm. 2010;67(24):2115–2118. doi: 10.2146/ajhp100151. [DOI] [PubMed] [Google Scholar]

- Lin A.C., Penm J., Ivey M.F., Deng Y., Commins M. Applying lean techniques to reduce intravenous waste through premixed solutions and increasing production frequency. J. Healthcare Qual. (JHQ) 2018;40(1):2–8. doi: 10.1097/JHQ.0000000000000043. [DOI] [PubMed] [Google Scholar]

- Newhouse J.G., Paul V.M., Waugh N.A., Frye C.B. Reducing iv waste to under 2.25 percent. Hospital Pharm. 1988;23(3):241–242. [PubMed] [Google Scholar]

- Paoletti R.D., Casey E.W. Reducing costs through centralization and standardization of an iv admixture program. Am. J. Health-System Pharm. 2000;57(12):1147–1149. [PubMed] [Google Scholar]

- Salberg D.J., Newton R.W., Leduc D.T. Cost of wastage in a hospital intravenous admixture program. Hospital Formulary. 1984;19(5):375–378. [PubMed] [Google Scholar]

- Toerper M.F., Veltri M.A., Hamrock E., Mollenkopf N.L., Holt K., Levin S. Medication waste reduction in pediatric pharmacy batch processes. J. Pediatr. Pharmacol. Therapeut. 2014;19(2):111–117. doi: 10.5863/1551-6776-19.2.111. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Uchida Kathryn M., Iteen Scott A., Wong Noreen T. Identifying costs of intravenous solution wastage. Pharmacoeconomics. 1994;6(3):240–248. doi: 10.2165/00019053-199406030-00008. [DOI] [PubMed] [Google Scholar]