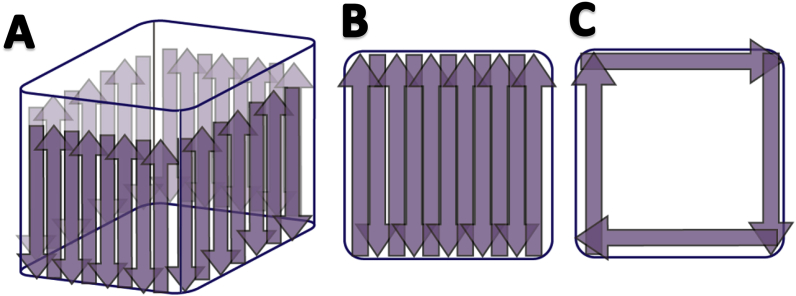

Fig. 8.

Schematic drawing of scraping procedure. A) Firstly, all surfaces of the walls were scraped in an up-and-down motion while pumping with the pipet. B) Secondly, the bottom were scraped in a back-and-forth motion while pumping with the pipet. C) Finally, the edge between the walls and bottom and the corners, were scraped while pumping the pipet, before the supernatant was removed, followed by another suction to insure removal of all fluid., followed by ultra-sonication (230 VAC, Branson, USA) of the whole plate in a regime of 5 min degassing followed by 5 min of ultra-sonication. The degassing step was used to remove excess gas build-up and bubbles in the samples, which could otherwise inhibits the effect of the ultra-sonication treatment. Biomass was subsequently pipetted out, before it was 10-fold serial diluted and plated on LB plates (1.5% agar). The effectiveness of biomass removal by means of both scraping and ultra-sonication was evaluated using CLSM, as described above.